KOIBIKE leverages its in-house carbon fiber custom molding technology to create the W60X28TL-UL wave rims. Their key breakthrough lies in the coordinated design of the 60mm high wave structure and the hook grooves. The factory supports mass customization for B2B customers, with complete control over the entire process, from cutting the wave-shaped carbon fabric, applying the white base coating, to precision processing of the hook grooves. The rims utilize Toray T700-grade carbon fiber, achieving a 60mm high wave shape through a variable curvature hot pressing process. The wave crests correspond to aerodynamic streamlines, while the troughs act as stress buffers. This eliminates the need for titanium alloy bushings, allowing the spoke holes to be wrapped in multiple layers of carbon fiber to ensure tensile strength. The 32mm outer width hook-edge groove creates a "mechanically interlocking and arc-shaped fit" with 25-47C tires, suitable for high tire pressures from 36 to 100 psi. The white rim uses a high-temperature cured white base material to prevent yellowing in the sun. With matte or color finishes, it not only meets aesthetic requirements but also enhances wear resistance through a ceramic composite coating.

High-Pressure Adaptive Wave Structure:

The 36-100 psi tire pressure range utilizes the innovative "dynamic stress dispersion" feature of the wave rim. At low tire pressures (36-50 psi), the troughs absorb gravel bumps through subtle deformation. At high tire pressures (80-100 psi), the carbon fiber layer in the crests adheres closely to the tire bead, dissipating the impact of tire pressure on the rim grooves. This reduces deformation by 15% compared to straight-edge rims at 100 psi, making it suitable for transitioning from road racing to light gravel driving.

Bushingless Lightweight and Strengthened:

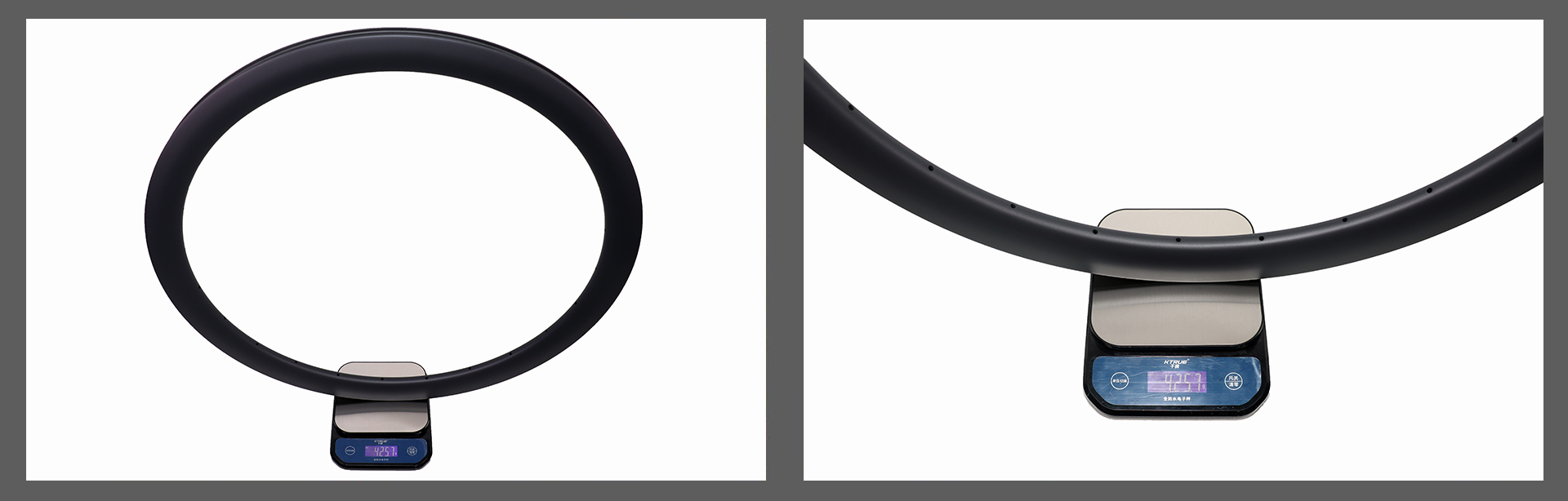

Eschewing traditional titanium bushings, this design utilizes a "three-layer carbon fiber wrap around the spoke holes + an annular stress distribution zone" to achieve a single-hole tensile strength of 420N. While 16% lower than bushing designs, the overall rim weight is reduced by 8% (approximately 40 grams). The 490 ± 15 grams weight is a significant advantage in a 60mm-deep rim, reducing rotational inertia by 12% when accelerating uphill.

Hook-edge Groove Tire Lock:

The hook-edge groove utilizes a "0.8mm raised hook claw + curved transition surface" design to mechanically lock with the tire bead. At a high tire pressure of 100psi, the risk of tire unseating is reduced by 90% compared to straight-edge rims. Furthermore, the curved connection between the hook edge and the wavy rim body reduces airflow separation at the groove, improving aerodynamic efficiency by 7% compared to conventional hook-edge rims.

White bezel technology breakthrough:

The white bezel utilizes "nano-scale white pigment + high-temperature curing resin" to avoid the yellowing problem of traditional white paint. UV aging tests show a color difference of ΔE ≤ 1.2 after 500 hours of exposure. Combined with a wave-patterned zoned coating technique, the coating thickness is 0.04mm at the wave crests (enhanced wear resistance) and 0.02mm at the wave troughs (reduced dust accumulation), resulting in a more consistent appearance.

Multiple coating options:

The full matte finish utilizes matte particle filler with a surface roughness of ≤1.0μm, perfect for a low-key style. The smoked black process uses a white bezel base followed by a dark dye to preserve the contrast of the wave texture. The paint-free version reveals the original carbon fiber grain, creating a contrasting "partial grain + overall white" design with the white bezel, achieving both lightweight and individual expression.

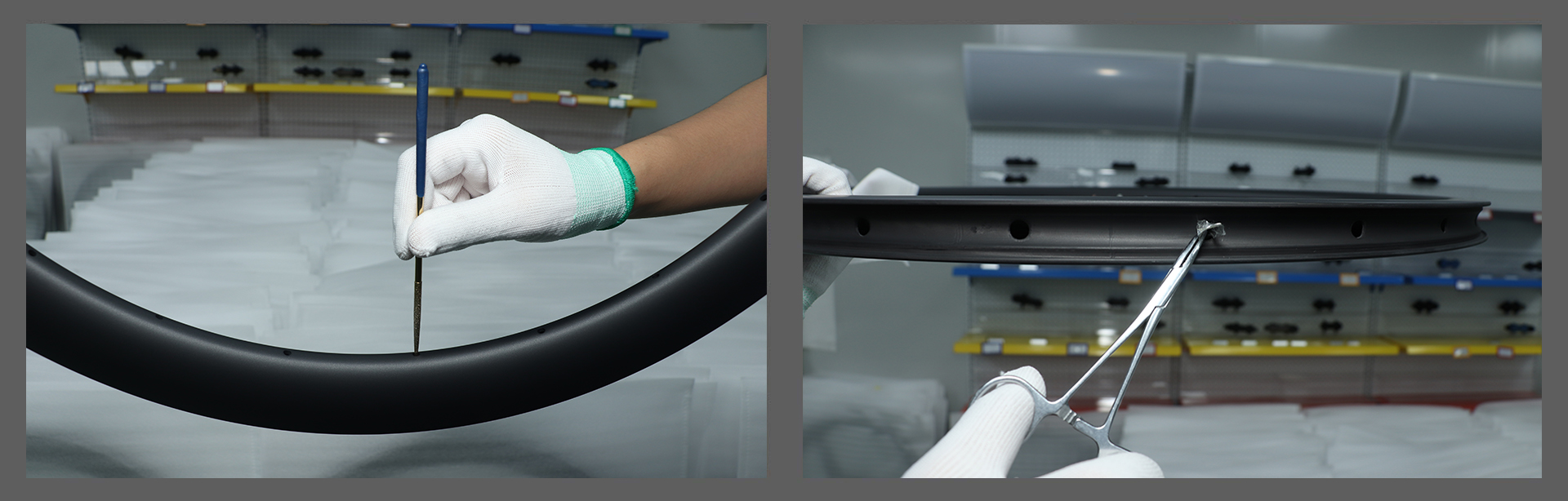

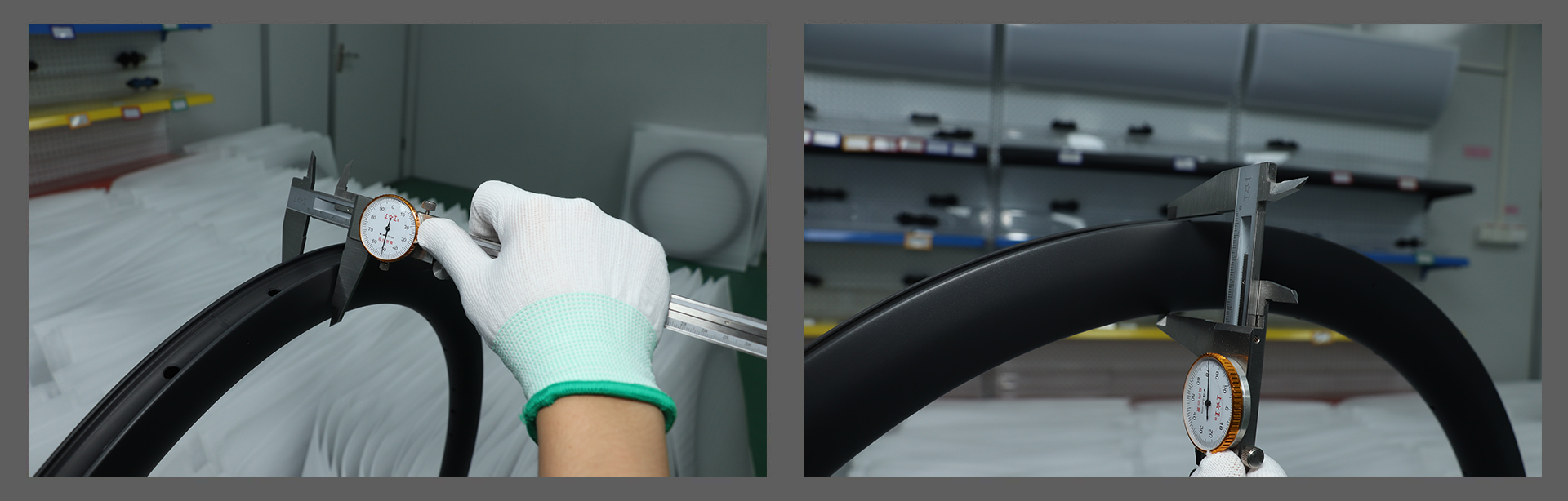

Strict Quality Control:

KOBIKE do 100% tire pressure(150 PSI), flatness(<0.2mm) and roundness(<0.2mm) inspections before shipping, also offering 2 years warranty for our carbon rims.

Wavy-Shaped Ring Details:

The 60mm-tall ring features a 60mm peak height and a 52mm trough depth, with uniform spacing of 45mm. Fluid dynamics simulations show that the curved leading edge of the wave crest guides airflow along the ring, reducing turbulence. Four carbon fiber layers are stacked at the crests (to enhance aerodynamic rigidity) and two layers at the troughs (to maintain cushioning toughness), achieving a structural layout that prioritizes aerodynamics while also balancing cushioning.

Bushing-Free Reinforced Spoke Holes:

The holes utilize a carbon fiber spiral wrapping process, and a 5mm-wide annular stress-distributing zone is designed on the outside of the hole opening to evenly distribute spoke tension along the wavy ring. While lacking a titanium alloy bushing, the optimized interlayer bond strength of the carbon fiber (up to 25MPa) prevents cracking of the spoke holes caused by bumpy roads, extending their service life by 20% compared to conventional bushing-free rings.

Hook-edge groove construction:

The hook edge is 2.2mm high, and the inner corners of the hooks are 0.5mm radiused to prevent bead scratches during tire installation. A single-step seal groove is located at the bottom of the groove. When used with a tubeless tire, the mechanical locking of the hook edge and the rubber seal of the seal groove ensure a 24-hour air leakage of ≤1.2psi at a high tire pressure of 100psi, making it suitable for high tire pressure requirements.

White rim coating process:

The white coating is applied in three layers: a base coat of white base material (for enhanced adhesion), a middle coat of color paint (for uniform color), and a top coat of ceramic protective coating (for improved wear resistance). The total thickness is 0.08mm, 30% thinner than a standard coating of the same color, without adding any additional weight. The wave pattern is applied using a "thin-coat gradient technique" to prevent buildup of coating that obscures the curvature of the wave.

Weight Restriction Reinforcement Area:

To meet the 120kg rider weight limit, the carbon fiber stacking density at the flange where the rim meets the hub is increased by 25%, forming a 10mm wide annular reinforcement band. Finite element analysis shows that stress at this location is 28% lower than in a standard area at a 120kg load. The wave structure also distributes stress at the flange toward the wave crest, preventing localized overload.

Application areas for the W60X28TL carbon bicycle rim:

Gravel Crossover:

With a 25-47cm tire range and 36-100cm tire pressure adjustment, combined with the wind resistance and cushioning of the wave rim, it allows for both high-speed cruising on paved roads with a narrow 25cm tire and low pressure on gravel roads with a wide 47cm tire. This makes it an ideal choice for gravel enthusiasts who enjoy a variety of riding styles. The wave structure's innovative stress distribution reduces rim damage on mixed terrain.

Road racing with light off-roading:

The aerodynamic advantages of the 60mm high-wave rim reduce wind resistance on road courses, while a high tire pressure of 100psi improves rolling efficiency. For occasional light gravel, reduce the tire pressure to 50psi. The trough cushioning reduces bumps, and the hooked rim grooves prevent tire derailment, making it ideal for racing enthusiasts seeking a versatile lap experience.

Long-distance mixed-terrain adventures:

The lightweight 490±15g and 120kg weight limit allow for easy carrying of essential riding gear. The white rim is highly visible in outdoor environments, and the bushing-free design reduces maintenance. The torsional resistance of the wave structure reduces energy loss during continuous climbing, making it ideal for multi-day, cross-country mixed-terrain adventures.

Personalized urban commuting upgrade:

The white rim with a paint-free original pattern or smoked black contrasting color creates a unique visual identity. The 32mm outer width is compatible with 32C puncture-resistant tires, balancing commuting efficiency with light off-road capability. The wave-shaped rim's wind-resistant design provides greater riding stability in urban crosswinds, enhancing the daily commuting experience.

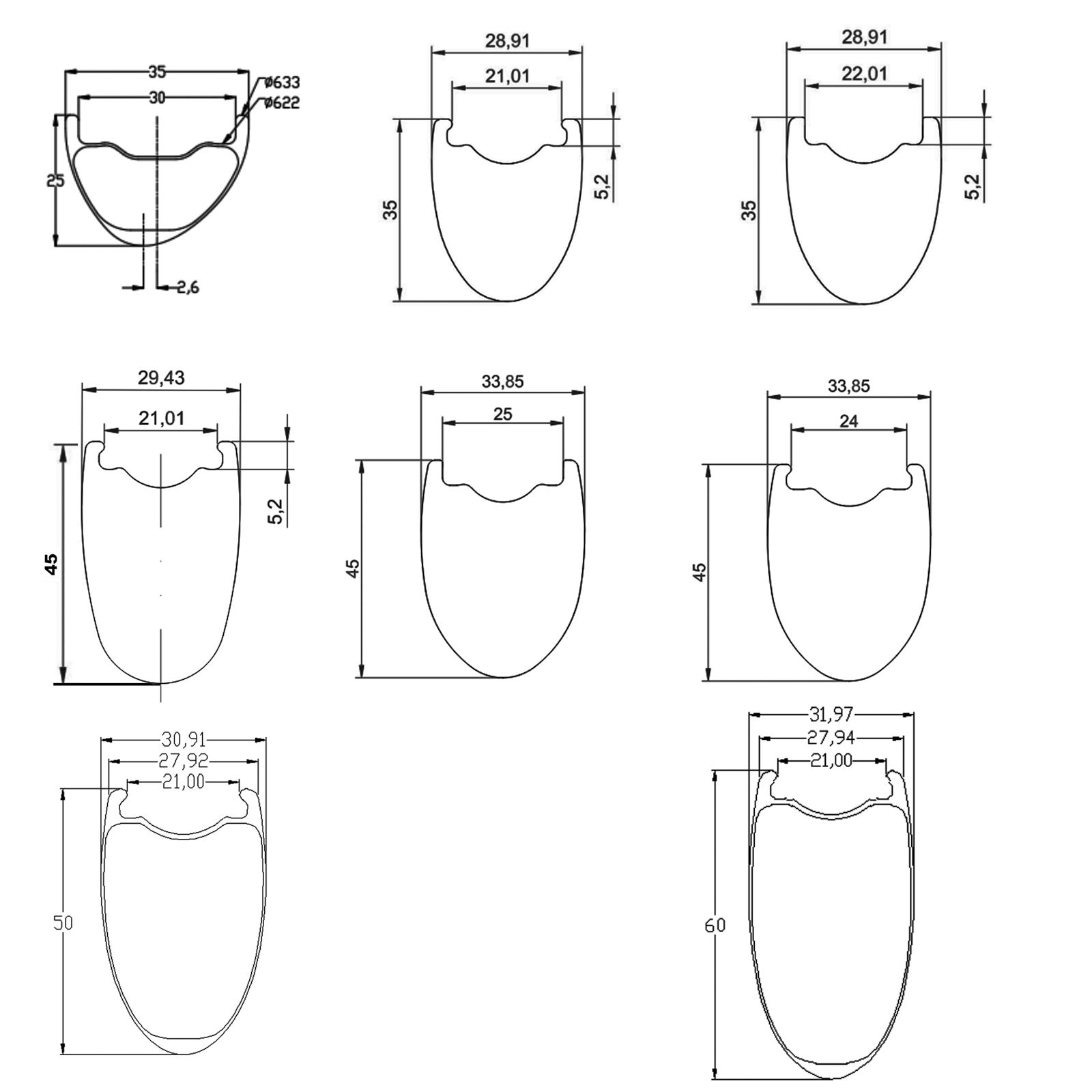

| Model | Weight(Gram) | Inner Width | Outer Width | Depth | Brake System | Available Appearance | Available Spoke Hole Counts |

| W35X28TL-SL | 360±15 | 21mm | 28mm | 35mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| W35X28TL-UL | 340±15 | 21mm | 28mm | 35mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| W35X28HL-SL | 360±15 | 22mm | 28mm | 35mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| W35X28HL-UL | 340±15 | 22mm | 28mm | 35mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| W45X28TL-UL | 380±15 | 21mm | 28mm | 45mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| W45X28HL-UL | 380±15 | 22mm | 28mm | 45mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| W50X28TL-NL | 490±15 | 21mm | 28mm | 50mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| W50X28TL-SL | 470±15 | 21mm | 28mm | 50mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| W50X28TL-SL | 430±15 | 21mm | 28mm | 50mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| W50X28TL-UL | 400±15 | 21mm | 28mm | 50mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| W60X28TL-NL | 530±15 | 21mm | 28mm | 60mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| W60X28TL-SL | 510±15 | 21mm | 28mm | 60mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| W60X28TL-UL | 490±15 | 21mm | 28mm | 60mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| W45X32TL-UL | 380±15 | 24mm | 32mm | 45mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| W45X32HL-UL | 380±15 | 25mm | 32mm | 45mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| XC-W25X35HL-29ER-SL | 360±15 | 30mm | 35mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-W25X35HL-29ER-UL | 320±15 | 30mm | 35mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

The above parameters are for reference only, please consult our engineers for specific technical parameters.

100% Customizable

Customized Weaves & Finishes:

Customized Holes:

![]()

Weight Check:

Clean burrs & residues:

Rim Diameters Check:

Cleaning:

Packing:

We have been in carbon bicycle production industry since the year of 2015, so 10 years history and experiences.

100 workers, 30 management, 20 Engineers, 10 Sales.

Carbon bicycle rims, carbon spokes, carbon wheels, cranks and other carbon bicycle components.

Our factory area is 2500 square meters, with 2 production lines, one wheel building line.

10.000 pcs/month for carbon rims, 100.000 pcs/month for carbon spokes, 10.000 pcs/month for other carbon bicycle components like cranks, handlebars, thru axles etc.

10-15 days for carbon rims(100-200 pcs), 7-10 days for carbon spokes, 25-30 days for carbon wheels.

It depend on the product models, quantities and and other factors, takes carbon rim for example, price generate from 80-130 USD per piece.

2 years for carbo rims and wheels, 1 year for carbon spokes.

We focus on OEM/ODM service for customers mainly on Europe and American markets.

We have signed confidential agreement with our big OEM customers, so not allow to tell, but the big brands from Europe and America.

Our factory locates in Xiamen, China.