The design and development of carbon fiber rims is not only a technical challenge, but also an ultimate pursuit of performance and aesthetics. KOIBIKE (KOI) combines material science, aerodynamics and precision manufacturing processes through continuous innovation, and is committed to creating lightweight, high-rigidity and aerodynamic carbon fiber rims. We provide customers with high-performance products with efficient and reliable mold development processes, while promoting the popularization of carbon fiber technology in the bicycle industry and promoting green travel.

KOIBIKE AERODYNAMIC RESEARCH

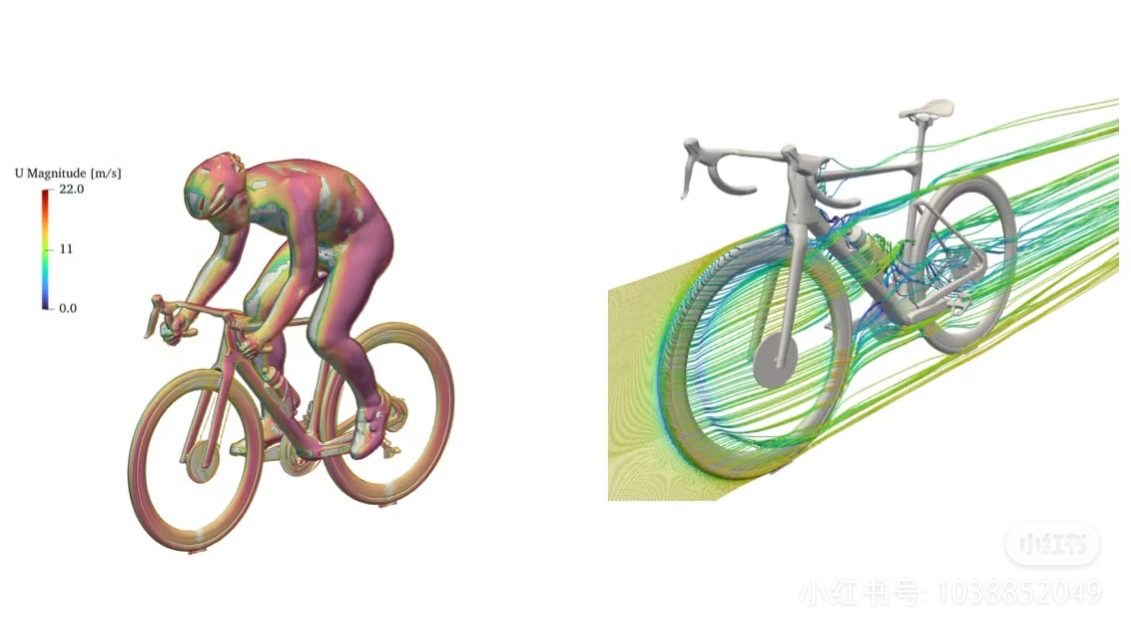

The aerodynamic performance of the rim directly affects riding efficiency, especially stability in high-speed scenarios. The KOI R&D team used CFD (Computational Fluid Dynamics) simulation technology from the initial design stage to analyze the wind resistance of the rim shape. By optimizing the transition curve between the rim edge curvature and the airflow contact surface (Figure 1), we ensure that the airflow separation point is minimized, turbulence generation is reduced, and wind resistance is reduced.

Rims Structure Design And Mechanical Analysis

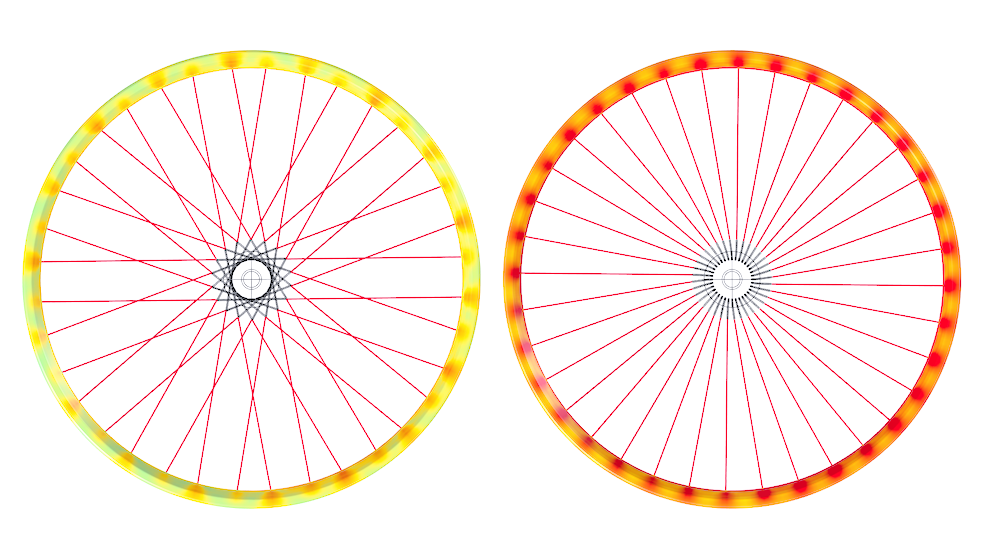

On the basis of aerodynamic optimization, the rims need to meet the requirements of high rigidity, impact resistance and light weight. KOI uses a multi-objective topology optimization algorithm, combined with the distribution of spoke holes on the rim, the structural characteristics of the brake edge (if applicable) and the tire lip contact area, to build a mechanical model (Figure 2). Through FEA simulation of the stress distribution of the rim under radial load (simulated riding support), lateral bending (simulated cornering) and impact load, it ensures that key areas (such as the brake edge and around the spoke holes) have redundant strength. At the same time, through iterative optimization of the layup angle and local reinforcement design, the best ratio of weight and rigidity is achieved.

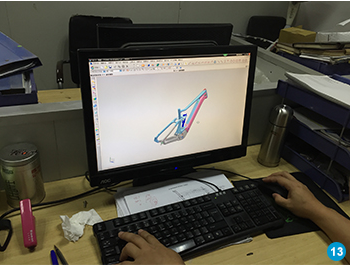

The KOI engineering team uses CAD software to design the wheel rim geometry (rim height, width, cross-sectional shape, etc.), combines CFD fluid mechanics data analysis and FEA to optimize force distribution, and draws 3D drawings (Figure 4).

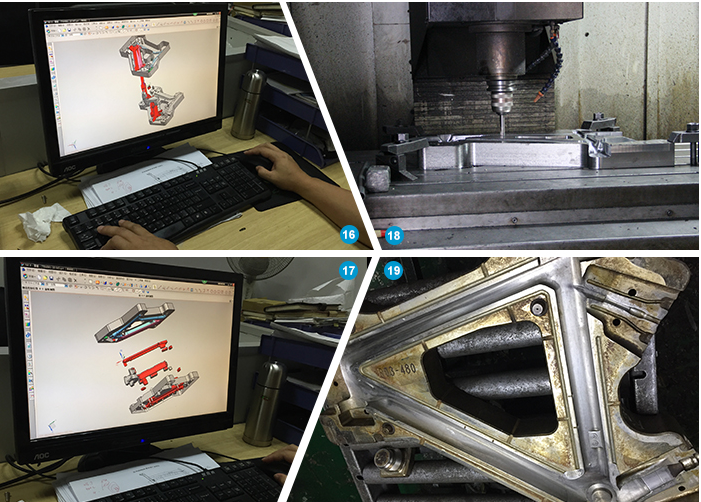

Rims Mold Development

Mold design is the core of rims mass production. KOI adopts a modular mold solution based on the 3D wheel rim model (Figure 5):

Rims Mold Verification And Finished Product Testing

The first sample needs to go through four stages of verification:

Dimension inspection: Use CMM to measure and compare the rim roundness, width and eccentricity (Figure 7);

Dynamic load test: simulates radial fatigue during riding (EN 14781 standard, 100,000 loadings) and lateral impact (ISO 5775 standard);

Destructive testing: overload to 150% of the design strength, analyze failure modes to optimize ply design;

Real vehicle road testing: Conduct long-distance comprehensive road condition tests in conjunction with professional teams to evaluate actual performance and durability.