As a high-end manufacturer deeply engaged in the field of carbon fiber composite materials, KOIBIKE has been focusing on the field of carbon fiber rims since 2015. With mature experience in road rims, mountain rims and gravel rims, we have extended cutting-edge material technology and precision manufacturing processes to the research and development and production of carbon fiber bicycle frames and accessories, and are committed to creating high-performance products that are both lightweight, high rigidity, aerodynamics and durable. The following are the core production processes and quality control systems of carbon fiber rims:

Rims Production Process

Carbon fiber cutting → preforming → high temperature and high pressure molding → precision machining → bonding and assembly → primer treatment → dynamic balance test → surface coating → full inspection and packaging → logistics and transportation

Note: Each process is subject to 100% inspection and can only proceed to the next stage after passing QC certification. For detailed quality control standards, please refer to the "Quality Control System" at the end of this article.

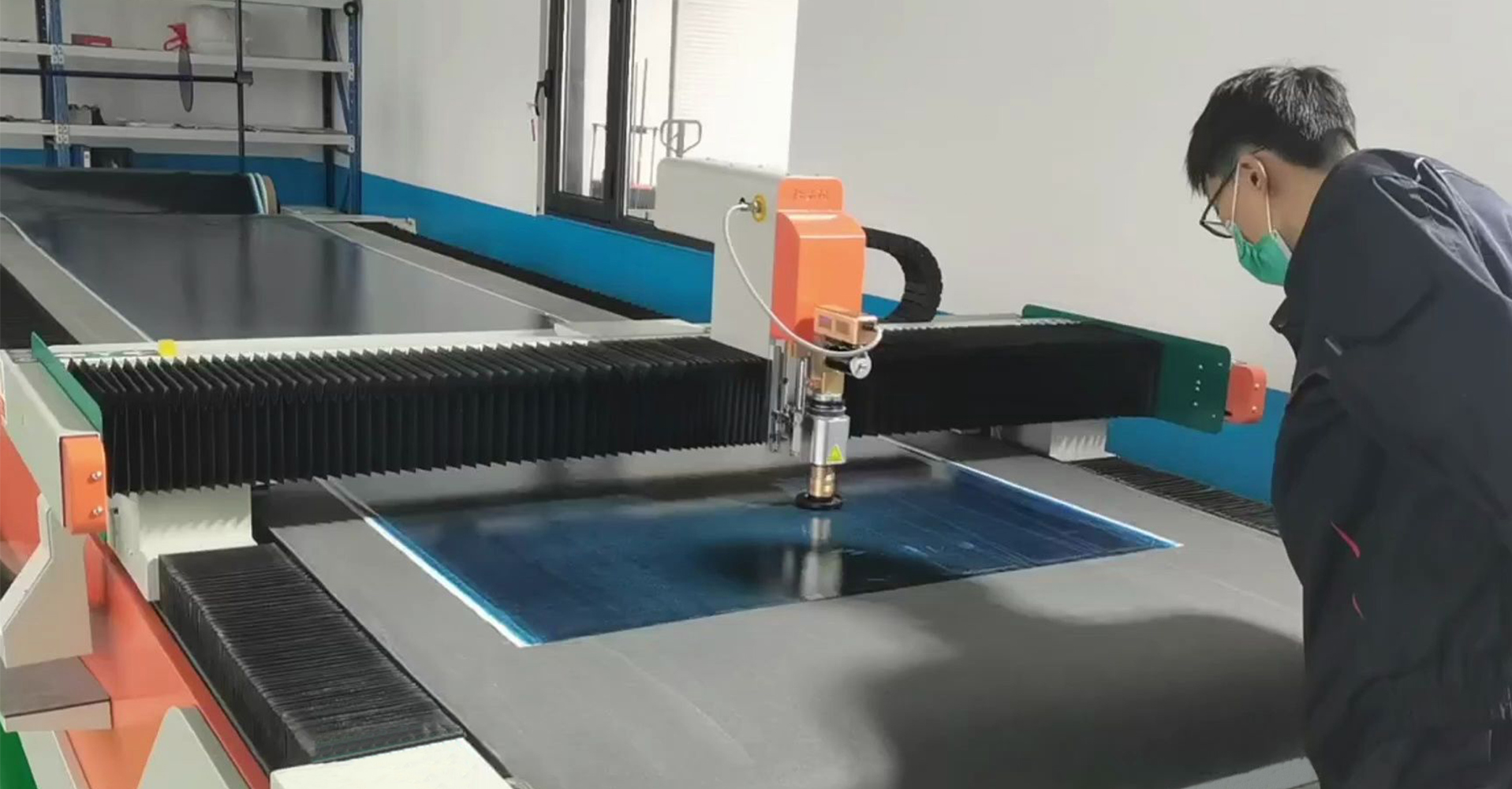

Carbon fiber prepreg cutting

Material management: Use Japan Toray T700/T800/T1000 grade carbon fiber prepreg, store in a constant temperature warehouse (5-18℃), use up within 10 days after opening, and the remaining material should be sealed and frozen (0-5℃).

Precision cutting: High-precision cutting is performed by an automated cutting machine. A single wheel rim requires 120-140 layers of carbon cloth. Special personnel classify and sort out the scraps to ensure material utilization and consistency of the layers.

Preforming Process

Lamination positioning: Vacuum-assisted molding technology is used, and laser is used to assist in positioning the carbon fiber cloth layer by layer. Key stress-bearing areas (such as brake edges and spoke holes) are directionally reinforced, and epoxy resin guide channels are pre-embedded.

Process standardization: Operators strictly follow the SOP to perform 150+ layering steps to ensure that the contour accuracy error of each wheel rim is ≤0.2mm, laying the structural foundation for subsequent high-temperature molding.

High Temperature And High Pressure Molding

A high pressure of 150 psi is applied in the mold, and the mold is cured at a constant temperature of 130°C for 1.5 hours to allow the resin to fully penetrate the fiber gaps and achieve the best strength/weight ratio.

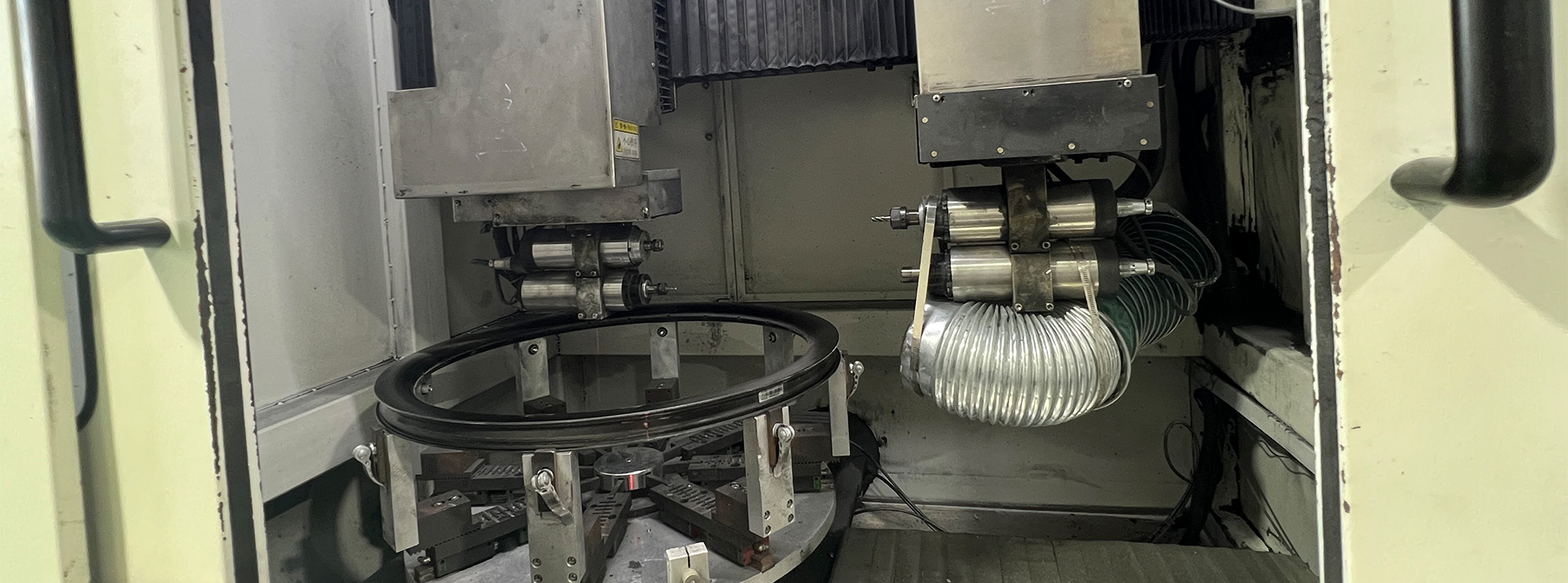

Precision Machining

Burr treatment: CNC machine tools cut off excess pipes, and mirror polish the brake surface and tire lip seat to ensure that the installation surface flatness is ≤0.1mm.

Structural reinforcement: The spoke holes are made using a fully automated machine tool drilling + chamfering process, combined with sandblasting roughening to improve bonding strength and eliminate micro cracks caused by stress concentration.

Ultrasonic Non-destructive Testing

X-ray testing is used to verify the integrity of the bonding surface and to remove semi-finished products with bubbles or delamination defects.

Dynamic performance Test

Radial fatigue test: simulate 120kg continuous impact for 100,000 times to detect the radial deformation of the rim (standard value <1.5mm).

Dynamic balance calibration: High-speed rotation test (>60km/h) ensures that the residual imbalance is less than 5g·cm to avoid shaking during high-speed riding.

Quality Control System

Raw material traceability: Samples of each batch of carbon fiber prepreg are retained and can be traced back to the Toray original factory batch number.

100% full inspection: Each process is equipped with a full-time QC to perform dimensional measurement (CMM), hardness test (Shore D hardness tester ≥90HD) and visual inspection.

Finished product certification: Passed EN 14781 (road rims) and EN 14766 (mountain bike rims) standard tests, and provides a 2-year warranty commitment.

KOIBIKE redefines the performance boundaries of carbon fiber wheels with military-grade quality control and innovative technology. From professional competitions to long-distance endurance riding, we inject reliable genes into every pair of wheels.