KOIBIKE leverages its in-house precision carbon fiber processing technology to create the W45X32TL-UL Wave rims. Their core breakthrough lies in elevating the "wave-shaped structure" from a decorative design to a functional innovation. The factory supports customizable coatings and parameter fine-tuning, offering complete control over the entire process, from carbon fiber cutting and wave lamination to finished product inspection. The rims utilize Toray T800-grade carbon fiber, achieving a wave-shaped profile through a "variable curvature lamination process." The 45mm peak-to-valley spacing is optimized through mechanical simulation, while the 32mm outer width provides stable support for wide tires. A 28-50cm tire range accommodates tires from hardtail off-road to all-mountain, while a 28-81cm tire pressure adjustment handles complex terrain such as gravel and mud. Among the various coating options, the paint-free process preserves the original carbon fiber grain and reduces weight by 6-8 grams, while a full matte coating enhances scratch resistance.

The wave structure offers torsional strength:

The unique wave-shaped rim utilizes a "dynamic stress dispersion" design, with wave crests corresponding to the spoke holes forming rigid support points and troughs acting as elastic buffers. This results in 18% greater torsional strength than a similarly sized straight-sided rim. When a 120kg rider negotiates corners or bumps, rim deflection is kept to within 0.2mm, preventing damage caused by localized stress concentration.

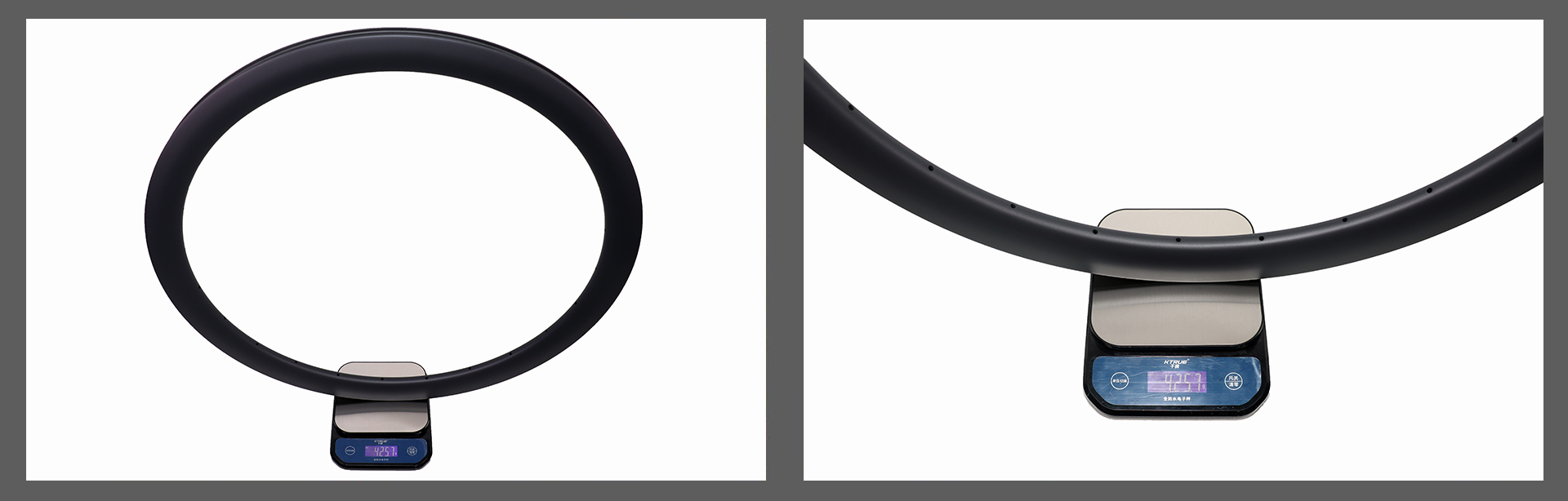

Extremely lightweight and efficient:

The 380±15g weight is achieved thanks to "wave-shaped optimized material distribution"—the wavy curves in non-stressed areas reduce carbon fiber usage, resulting in an 8% reduction in material consumption compared to traditional straight-sided rims. The high strength of T800 carbon fiber ensures load-bearing performance and improves climbing acceleration by 12%.

Wide Tire Compatibility and Sealing:

The 32mm outer width combined with the wavy bead creates a "curved fit" with tires ranging from 28-50cm, increasing the sealing area by 15% compared to straight-sided rims. Compatible with tire pressures ranging from 28-81cm, the bead securely engages the wavy grooves at low pressures, providing a high level of airtightness that reduces the risk of air leakage after a puncture on gravel roads.

Safety Weight Limit:

To meet the 120kg rider weight limit, the wave rim features an additional layer of carbon fiber reinforcement at the flange. A wave-shaped stress-distribution zone is used around the spoke holes, allowing a single hole to withstand up to 300kg of tension, a 20% increase over conventional designs, providing enhanced structural stability during loaded riding.

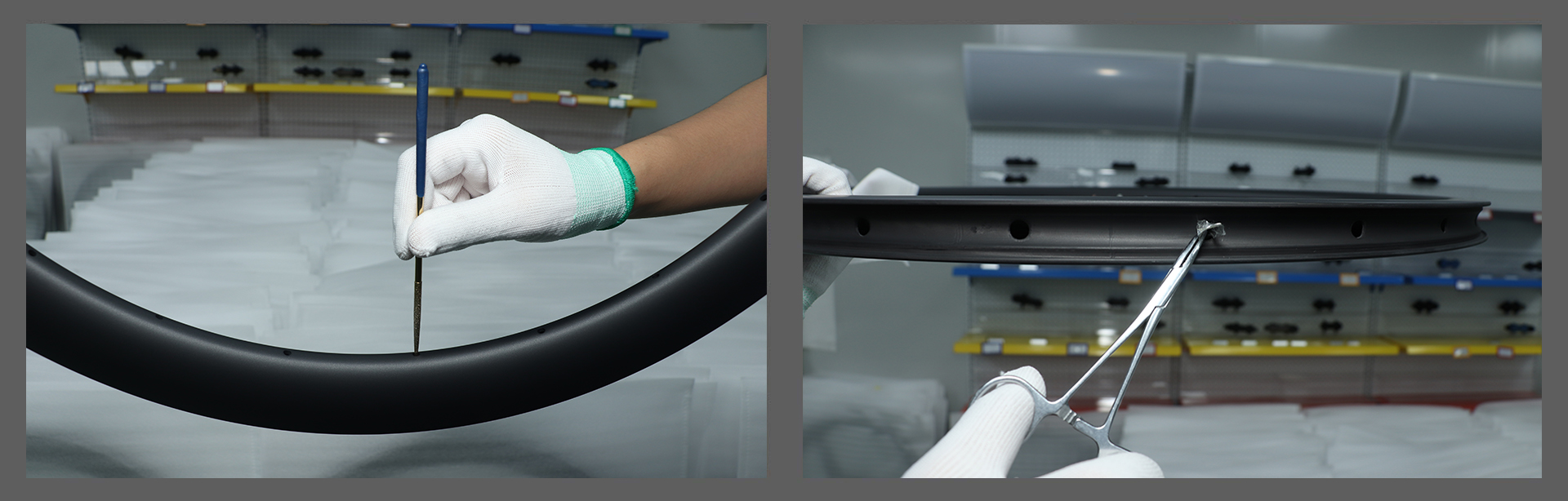

Strict Quality Control:

KOBIKE do 100% tire pressure(150 PSI), flatness(<0.2mm) and roundness(<0.2mm) inspections before shipping, also offering 2 years warranty for our carbon rims.

Wave-shaped rim details:

The rim's peak height is 45mm, the trough depth is 38mm, and the spacing is evenly distributed at 50mm. Optimized for fluid dynamics, this reduces crosswind interference. Three carbon fiber layers are stacked at the crests and two at the troughs, achieving a precise balance of rigidity and lightweight.

Spoke Hole Reinforcement System:

A wave-shaped stress-distribution ring surrounds the outside of the rim, evenly distributing spoke tension to the rim. Combined with the wave structure, spoke tension tolerance is controlled within 5%, and radial runout is ≤0.1mm during rotation.

Bead Seal Design:

The inner side features a wave-shaped, conformable seal that complements the curved structure of the tubeless tire lip, creating a double seal. At 81psi, 24-hour air leakage is ≤0.8psi. Both straight-edge and hook-edge bead grooves are available to accommodate a wide range of tire pressures.

Adaptive Coating:

The wavy surface utilizes a zoned coating technique—coating thickness is 0.03mm at the wave crests (for enhanced wear resistance) and 0.02mm at the wave troughs (to reduce dust accumulation). This prevents coating buildup and missing coatings that can occur with uniform flat coating within the wavy texture, resulting in a more consistent appearance.

Reinforced Weight Zone:

The flange where the rim meets the hub features a wave-shaped, thickened design. The carbon fiber stacking density is increased by 30%, creating a circular reinforcement band. In a 120kg load test, stress levels in this area were reduced by 22% compared to the normal zone, effectively extending tire life.

Application areas for the W45X32HL carbon bicycle rim:

All-Mountain Flexible Riding:

The wave structure's torsion resistance and cushioning properties make it suitable for steep slopes and bumpy sections in all-mountain riding. Wide 28-50cm tires paired with low tire pressures easily handle muddy and gravel terrain, providing stable control for the rider.

Light Cross-Country Racing:

The ultra-light weight of 380 grams reduces rotational inertia, and the 45mm high wave-shaped cross-section reduces wind resistance, making it suitable for flat sprints and climbs in light cross-country events, helping riders conserve energy and improve performance.

Long-Distance Mixed Terrain Riding:

The wide tire compatibility and high airtightness allow it to carry additional loads such as camping gear. The wave coil's shock absorption reduces hand fatigue on long rides, making it ideal for multi-day, cross-country, mixed-terrain adventures.

High-End Cross-Country Vehicles:

As a core component of high-end hardtail or all-mountain bikes, the wave structure's innovative design and lightweight performance enhance the vehicle's market competitiveness, attracting consumers who value performance and differentiation.

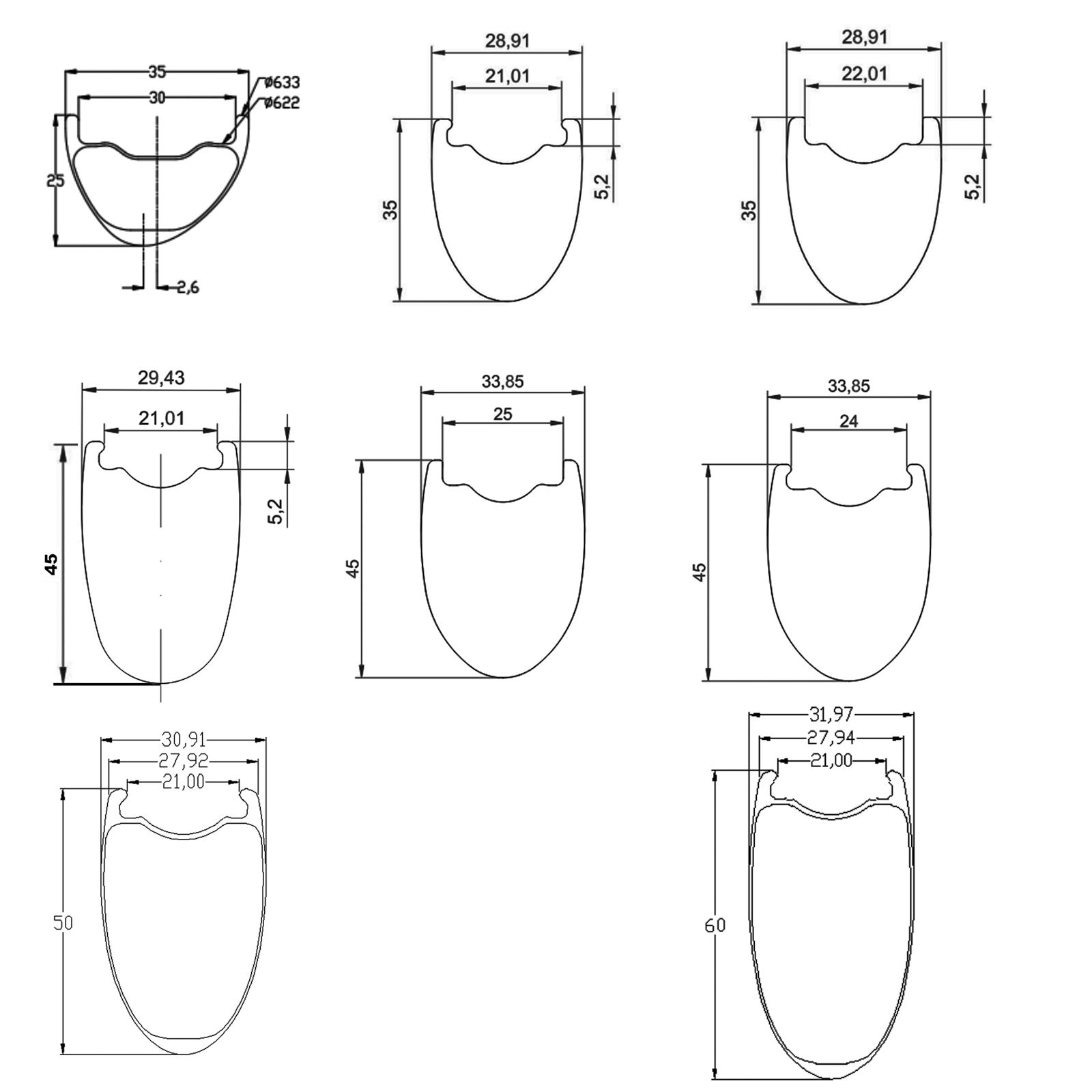

| Model | Weight(Gram) | Inner Width | Outer Width | Depth | Brake System | Available Appearance | Available Spoke Hole Counts |

| W35X28TL-SL | 360±15 | 21mm | 28mm | 35mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| W35X28TL-UL | 340±15 | 21mm | 28mm | 35mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| W35X28HL-SL | 360±15 | 22mm | 28mm | 35mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| W35X28HL-UL | 340±15 | 22mm | 28mm | 35mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| W45X28TL-UL | 380±15 | 21mm | 28mm | 45mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| W45X28HL-UL | 380±15 | 22mm | 28mm | 45mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| W50X28TL-NL | 490±15 | 21mm | 28mm | 50mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| W50X28TL-SL | 470±15 | 21mm | 28mm | 50mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| W50X28TL-SL | 430±15 | 21mm | 28mm | 50mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| W50X28TL-UL | 400±15 | 21mm | 28mm | 50mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| W60X28TL-NL | 530±15 | 21mm | 28mm | 60mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| W60X28TL-SL | 510±15 | 21mm | 28mm | 60mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| W60X28TL-UL | 490±15 | 21mm | 28mm | 60mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| W45X32TL-UL | 380±15 | 24mm | 32mm | 45mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| W45X32HL-UL | 380±15 | 25mm | 32mm | 45mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| XC-W25X35HL-29ER-SL | 360±15 | 30mm | 35mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-W25X35HL-29ER-UL | 320±15 | 30mm | 35mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

The above parameters are for reference only, please consult our engineers for specific technical parameters.

100% Customizable

Customized Weaves & Finishes:

Customized Holes:

![]()

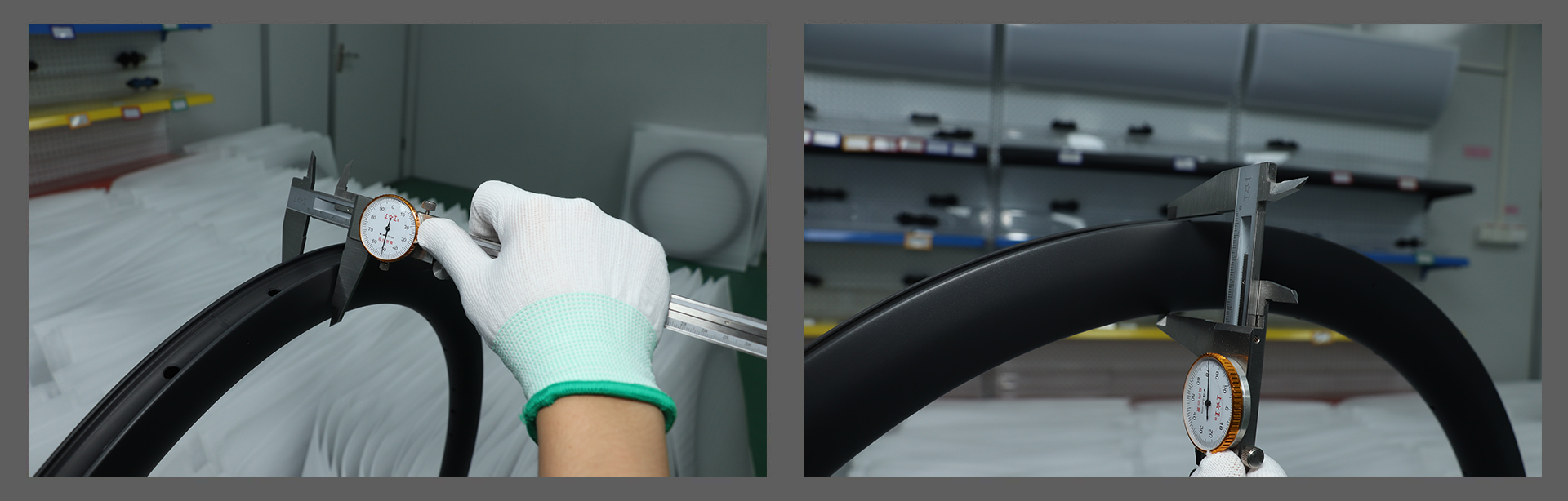

Weight Check:

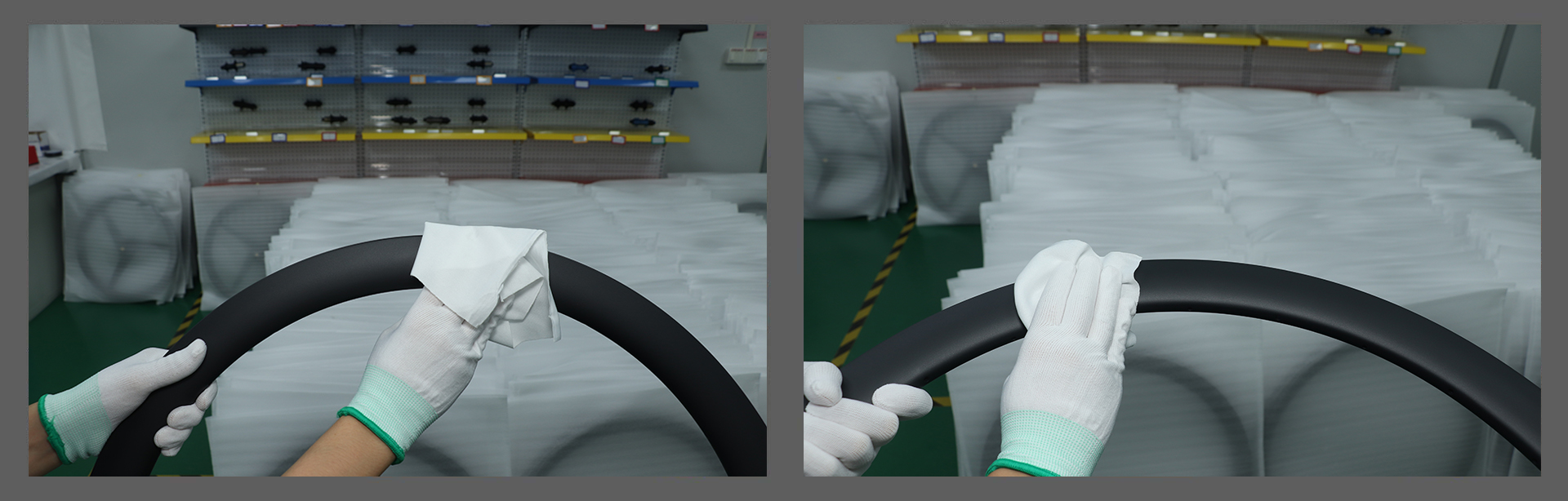

Clean burrs & residues:

Rim Diameters Check:

Cleaning:

Packing:

We have been in carbon bicycle production industry since the year of 2015, so 10 years history and experiences.

100 workers, 30 management, 20 Engineers, 10 Sales.

Carbon bicycle rims, carbon spokes, carbon wheels, cranks and other carbon bicycle components.

Our factory area is 2500 square meters, with 2 production lines, one wheel building line.

10.000 pcs/month for carbon rims, 100.000 pcs/month for carbon spokes, 10.000 pcs/month for other carbon bicycle components like cranks, handlebars, thru axles etc.

10-15 days for carbon rims(100-200 pcs), 7-10 days for carbon spokes, 25-30 days for carbon wheels.

It depend on the product models, quantities and and other factors, takes carbon rim for example, price generate from 80-130 USD per piece.

2 years for carbo rims and wheels, 1 year for carbon spokes.

We focus on OEM/ODM service for customers mainly on Europe and American markets.

We have signed confidential agreement with our big OEM customers, so not allow to tell, but the big brands from Europe and America.

Our factory locates in Xiamen, China.