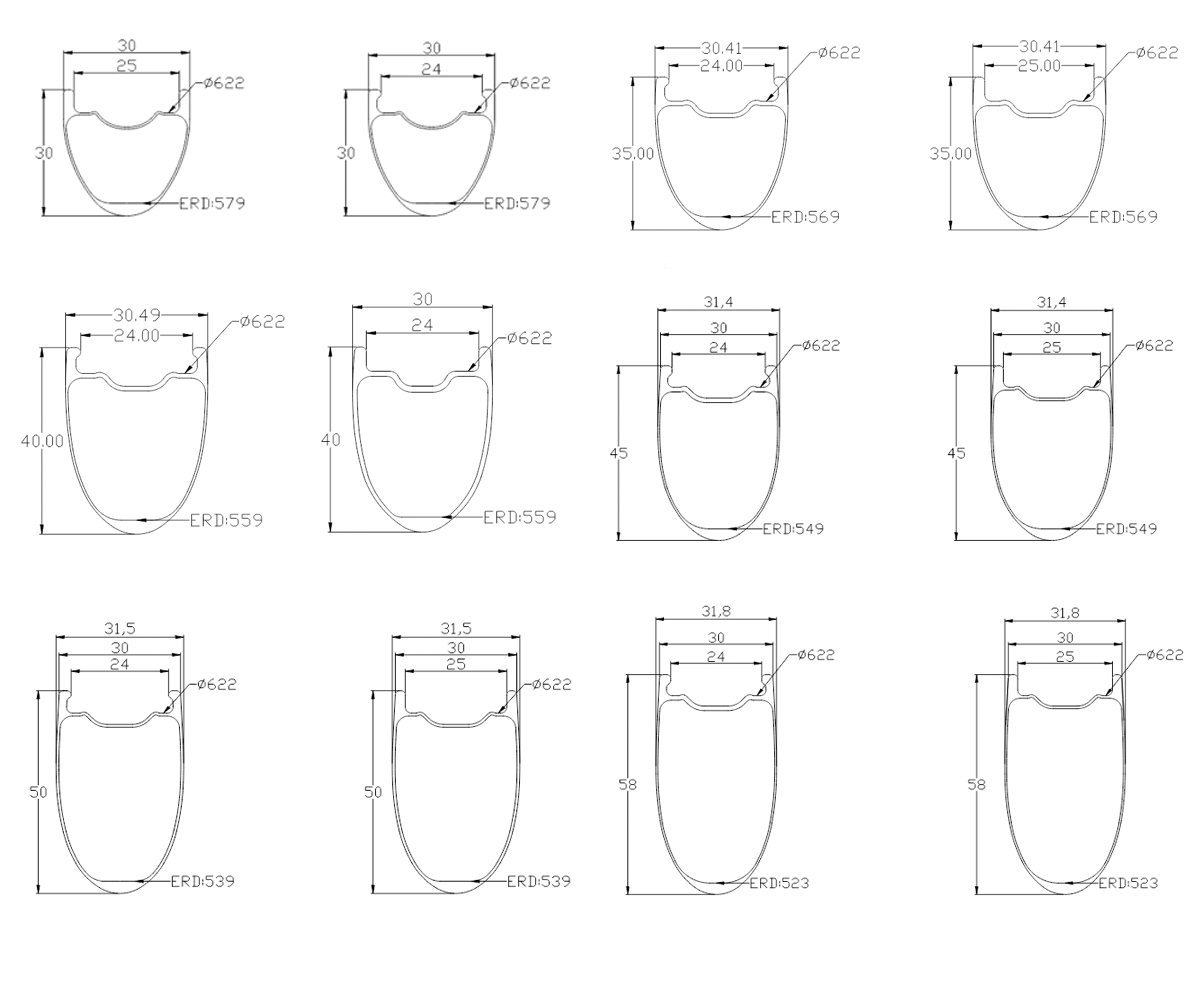

KOIBIKE's D45X30TL/HL-UL lightweight disc brake road wheelset is a core product produced by the factory. Leveraging years of experience in the carbon fiber wheel industry, the factory integrates R&D, production, and sales, ensuring a comprehensive supply chain. This wheel is constructed using Toray T700-T1100 grade carbon fiber fabric from Japan, formed through a lamination process and high-temperature curing technology. The 45mm rim increases control and flexibility, and the 24mm inner width and 30mm outer width allow for use with 28-50c tires, effectively reducing resistance. The straight-side rim supports vacuum tires, while the hook-edge (HL) rim is compatible with both vacuum tires and open tires. The single-rim weight is 385±15g, achieving a perfect balance between lightness and rigidity. The UD paint finish is the most stable coating method, resistant to scratches and sunlight. With independent production capabilities, we support customized spoke hole counts and carbon fiber fabric customization, providing a stable source of products to global trading partners, professional racing teams, and automakers. Road bike Tubeless ultral weight rim wheels 700c rim brake

Diverse tire compatibility:

The straight-side rim is designed for tubeless tires and offers reliable sealing, while the hook-side rim is compatible with both tubeless and clincher tires, catering to diverse user preferences and expanding application scenarios.

Lightweight and agile:

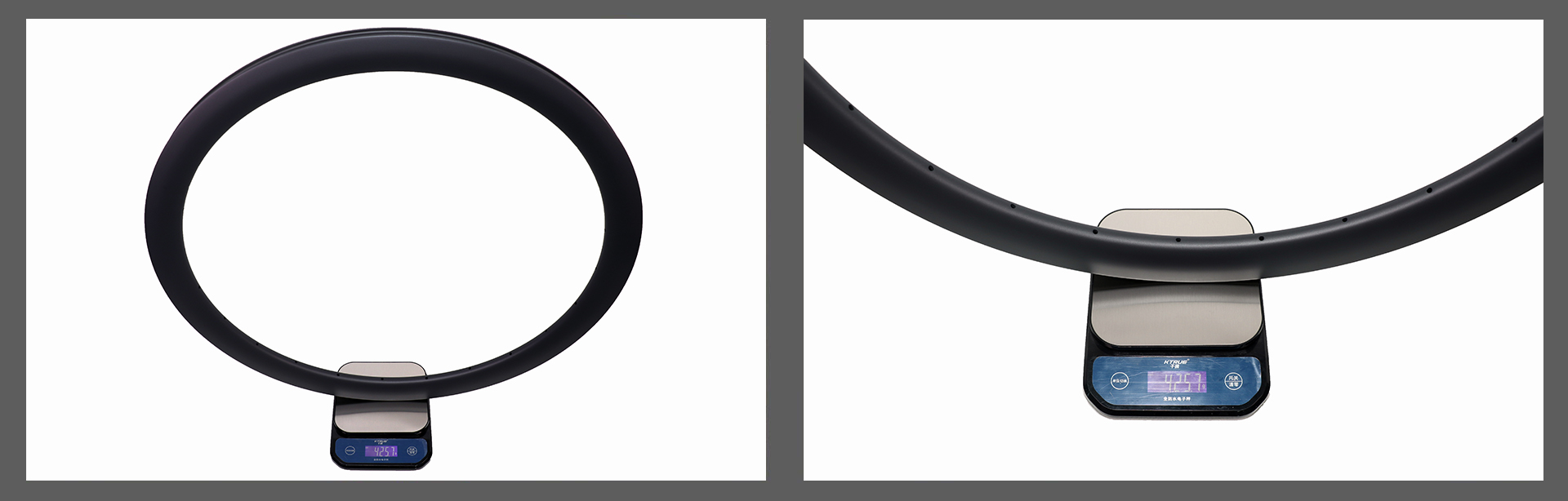

A 45mm rim depth provides agile handling, and the 385±15g lightweight design significantly reduces rotational inertia, making acceleration and climbing easier.

Safe and reliable braking:

The 30mm wide brake track, combined with the heat-resistant properties of carbon fiber, provides efficient heat dissipation and minimizes thermal decay during continuous braking, ensuring a safe ride.

Strong structural rigidity:

Utilizing Toray carbon fiber with factory-optimized layup, the rim offers excellent torsional and deformation resistance, ensuring direct pedaling power and stable cornering.

Quick customization:

Leveraging our factory's in-house production capabilities, we support customization of spoke hole counts (e.g., 24/28/32/36 holes) and carbon fiber types, quickly meeting the individual needs of our customers.

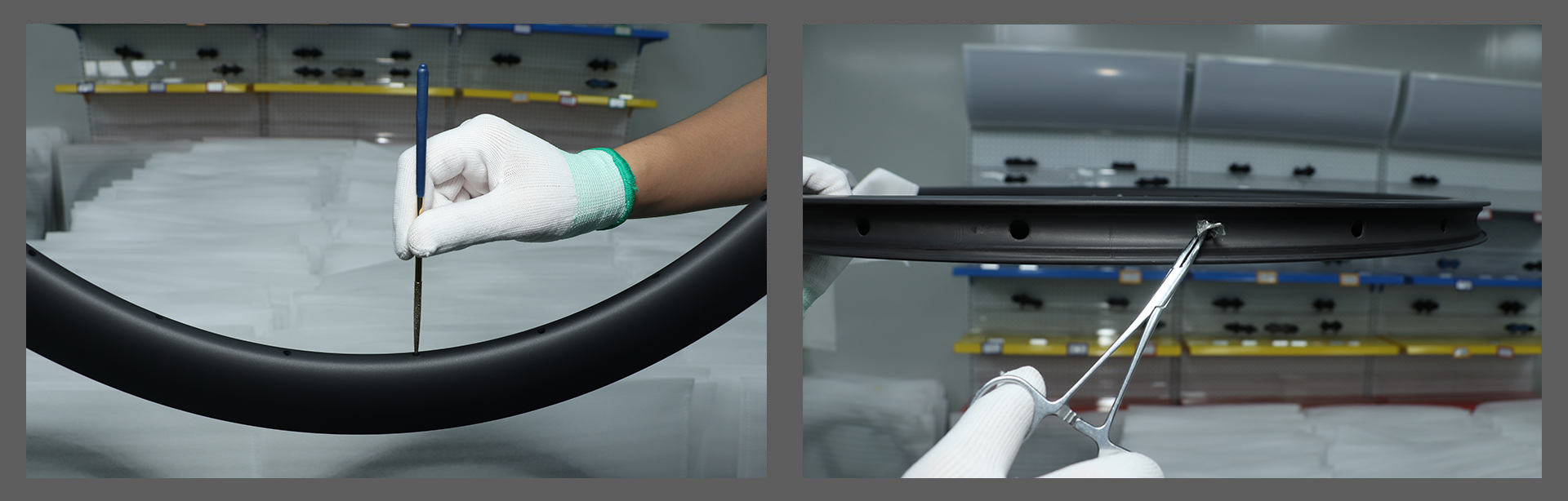

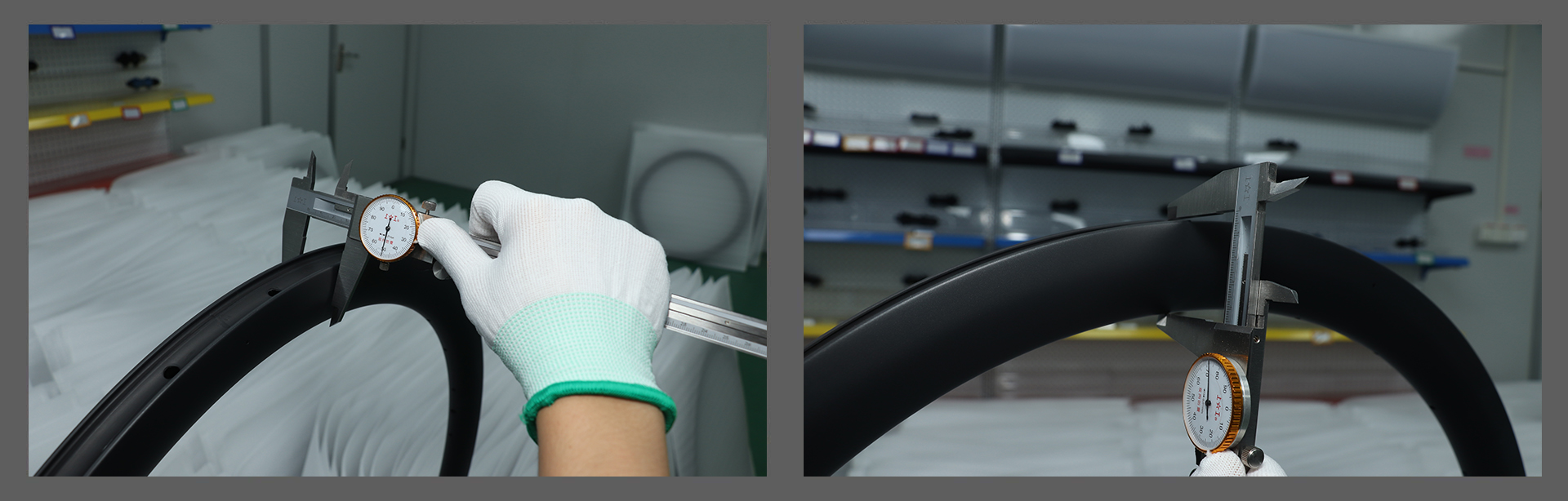

Strict Quality Control:

KOBIKE do 100% tire pressure(150 PSI), flatness(<0.2mm) and roundness(<0.2mm) inspections before shipping, also offering 2 years warranty for our carbon rims.

Spoke Hole Design:

Customizable spoke hole counts are available in various sizes. Holes are treated with our proprietary carbon fiber reinforcement wrapping process to evenly distribute spoke tension, accommodate various lacing methods, and enhance overall wheel rigidity.

Rim Appearance:

The rim is fully coated with a matte UD paint finish, with the carbon fiber grain clearly visible. The surface is treated with a special factory-applied wear-resistant coating that is scratch-resistant and UV-resistant, combining industrial aesthetics with practical durability.

Brake Track Structure:

The 30mm wide design features a flat straight-edge design for a secure seal with the tubeless tire bead. The hook-edge design features mechanical snap-in grooves for tubeless-compatible sealing and clincher retention, providing a smooth and stable braking contact surface.

Rim Body and Aerodynamic Construction:

The streamlined rim, with a 45mm deep rim and 30mm outer width, is factory-optimized for aerodynamics to minimize airflow interference. The carbon fiber layup is strategically adjusted to distribute force, enhancing stiffness while maintaining a lightweight design.

Application areas for the D45X30TL/HL-UL carbon bicycle rim:

Road Cycling Training:

Its lightweight and agile features make it suitable for daily road training and help riders improve their riding efficiency.

Sprint Racing:

Its balanced aerodynamic performance and flexible handling make it suitable for a variety of short-distance racing events, helping riders achieve top results.

Cycling Equipment Trading:

Factory-direct products are suitable for traders, expanding their market share with premium performance and customization.

Original Vehicle Manufacturer Support:

Customized production is supported, adapting to the assembly of road bikes of varying positioning, providing manufacturers with cost-effective wheel rim solutions.

Club and Team Purchasing:

The hook-rim style's tire compatibility meets the diverse tire needs of club and team members, facilitating unified purchasing and management.

| Model | Weight (Gram) | Brake System | Inner Width | Outer Width | Depth | Available Appearance | Available Spoke Hole Counts |

D30X30TL/HL-NL | 400±15g | Disc Brake | 24mm | 30mm | 30mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D30X30TL/HL-SL | 380±15g | Disc Brake | 24mm | 30mm | 30mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D30X30TL/HL-UL | 330±15g | Disc Brake | 24mm | 30mm | 30mm | UD | 16/18/20/21/24/28/32/36H |

D35X30TL/HL-NL | 415±15g | Disc Brake | 24mm | 30mm | 35mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D35X30TL/HL-SL | 395±15g | Disc Brake | 24mm | 30mm | 35mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D35X30TL/HL-UL | 350±15g | Disc Brake | 24mm | 30mm | 35mm | UD | 16/18/20/21/24/28/32/36H |

D40X30TL/HL-NL | 430±15g | Disc Brake | 24mm | 30mm | 40mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D40X30TL/HL-SL | 410±15g | Disc Brake | 24mm | 30mm | 40mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D40X30TL/HL-UL | 365±15g | Disc Brake | 24mm | 30mm | 40mm | UD | 16/18/20/21/24/28/32/36H |

| D40X30TL/HL-650B-NL | 410±15g | Disc Brake | 24mm | 30mm | 40mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| D40X30TL/HL-650B-NL | 390±15g | Disc Brake | 24mm | 30mm | 40mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| D40X30TL/HL-650B-NL | 345±15g | Disc Brake | 24mm | 30mm | 40mm | UD | 16/18/20/21/24/28/32/36H |

D45X30TL/HL-NL | 450±15g | Disc Brake | 24mm | 30mm | 45mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D45X30TL/HL-SL | 430±15g | Disc Brake | 24mm | 30mm | 45mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D45X30TL/HL-UL | 385±15g | Disc Brake | 24mm | 30mm | 45mm | UD | 16/18/20/21/24/28/32/36H |

D50X30TL/HL-NL | 470±15g | Disc Brake | 24mm | 30mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D50X30TL/HL-SL | 450±15g | Disc Brake | 24mm | 30mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D50X30TL/HL-UL | 400±15g | Disc Brake | 24mm | 30mm | 50mm | UD | 16/18/20/21/24/28/32/36H |

| FB25X80-24ER | 580±15g | Disc Brake | 75mm | 80mm | 25mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| FB25X65-26ER | 600±15g | Disc Brake | 60mm | 65mm | 25mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| FB25X80-26ER | 680±15g | Disc Brake | 75mm | 80mm | 25mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| FB25X100-26ER | 750±15g | Disc Brake | 95mm | 100mm | 25mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

FB28X80-27.5ER | 615±15g | Disc Brake | 74mm | 80mm | 28mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

FB40X85-27.5ER | 660±15g | Disc Brake | 79mm | 85mm | 40mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| BR/BD50X25TL-20”-406-NL | 320±15g | Rim/Disc Brake | 18.4mm | 25mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| BR/BD50X25TL-20”-406-UL | 290±15g | Rim/Disc Brake | 18.4mm | 25mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| BR/BD50X25TL-20”-451-NL | 355±15g | Rim/Disc Brake | 18.4mm | 25mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| BR/BD50X25TL-20”-451-UL | 320±15g | Rim/Disc Brake | 18.4mm | 25mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

100% Customizable

Customized Weaves & Finishes:

Customized Holes:

![]()

Weight Check:

Clean burrs & residues

Rim Diameters Check:

Cleaning & Packing

D45X30TL/HL-UL Product Show

We have been in carbon bicycle production industry since the year of 2015, so 10 years history and experiences.

100 workers, 30 management, 20 Engineers, 10 Sales.

Carbon bicycle rims, carbon spokes, carbon wheels, cranks and other carbon bicycle components.

Our factory area is 2500 square meters, with 2 production lines, one wheel building line.

10.000 pcs/month for carbon rims, 100.000 pcs/month for carbon spokes, 10.000 pcs/month for other carbon bicycle components like cranks, handlebars, thru axles etc.

10-15 days for carbon rims(100-200 pcs), 7-10 days for carbon spokes, 25-30 days for carbon wheels.

It depend on the product models, quantities and and other factors, takes carbon rim for example, price generate from 80-130 USD per piece.

2 years for carbo rims and wheels, 1 year for carbon spokes.

We focus on OEM/ODM service for customers mainly on Europe and American markets.

We have signed confidential agreement with our big OEM customers, so not allow to tell, but the big brands from Europe and America.

Our factory locates in Xiamen, China.