In the evolution of high-performance road wheels, the combination of a 55mm rim depth and a 21mm internal width is becoming a crucial link between engineering rationality and ergonomic response. The KOIBIKE D55X28TL-UL is a self-developed product built on this principle—it goes beyond simply achieving a balance between climbing and cruising, offering a comprehensive solution tailored to the real-world riding experience.

The rim is constructed from Toray's high-modulus carbon fiber, utilizing Graded Layup Technology to achieve structural and functional zoning. The spoke anchorage area enhances tensile rigidity, ensuring efficient power transmission; while the rim's crown incorporates a high-tenacity fabric to absorb high-frequency road impacts and reduce fatigue accumulation in the rider's upper limbs. This material strategy ensures a single-rim weight of 420 ± 15g while still passing thousands of impact cycles. It supports a maximum tire pressure of 120 psi, making it suitable for riders weighing 120 kg or less, achieving a balance between lightweight and long-term durability.

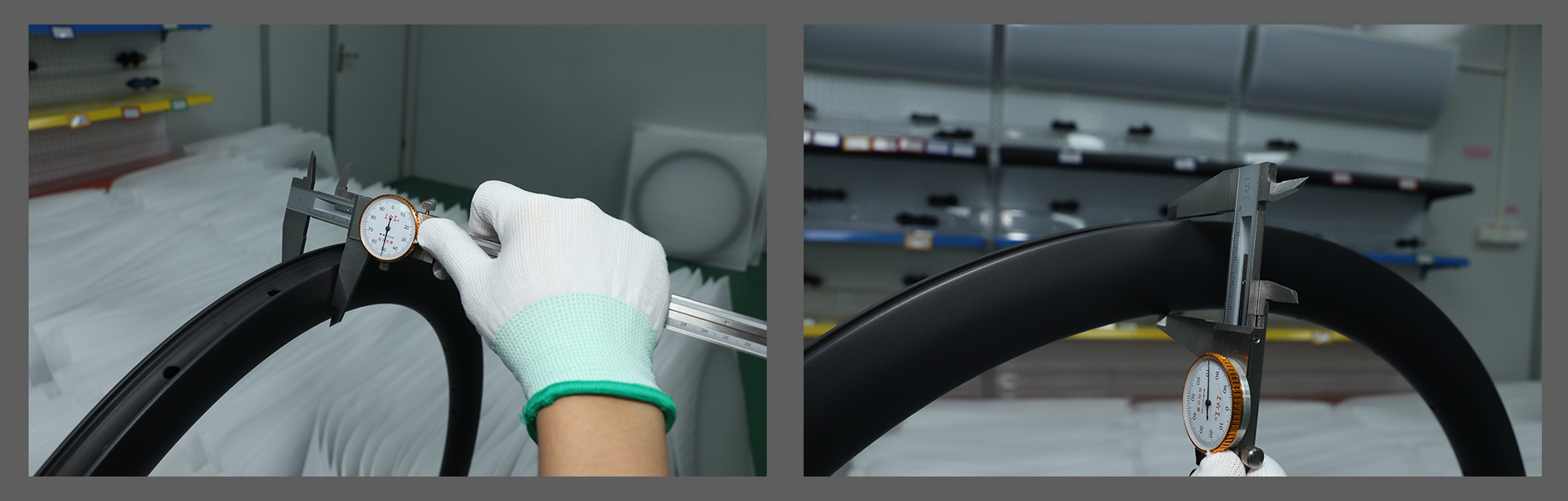

Precise Geometry and Stable Performance:

Featured by roundness tolerance within 0.3mm and flatness deviation within 0.2mm, the wheels are precision CNC machined and laser calibrated.

The advantages include smooth rim rotation, reduced rolling resistance, prevented abnormal tire wear, and uniform brake contact, enhancing ride smoothness and safety, making them suitable for high-intensity racing and long-distance training.

Excellent Rigidity:

Featured by the use of Japanese Toray carbon fiber (available in T700, T800, T1000, and T1100 densities), the optimized lamination process enhances overall rigidity.

The advantages include minimal deformation during pedaling, high power transmission efficiency, and excellent torsional resistance during cornering. It can handle high power output and complex road conditions, ensuring stable competitive performance.

Flexible Materials and Customization Options:

Features a choice of Toray carbon fabrics with varying densities: T700 balances strength and cost, T800 enhances rigidity and lightweight, and T1000/T1100 maximize performance. The spoke hole count can also be customized to accommodate diverse lacing requirements.

This rim offers the advantage of meeting the differentiated performance and cost requirements of different customers, enhancing product adaptability and facilitating mass customization for specific B-end customers.

Appearance and Supply Chain Advantages:

Its gold-finished marble finish is scratch-resistant and sun-resistant, and it's directly supplied by our own independent R&D and manufacturing company. Its unique appearance and durability are advantages, offering B2B customers the convenience of bulk purchasing and stable supply chain support, making it suitable for both competition and training.

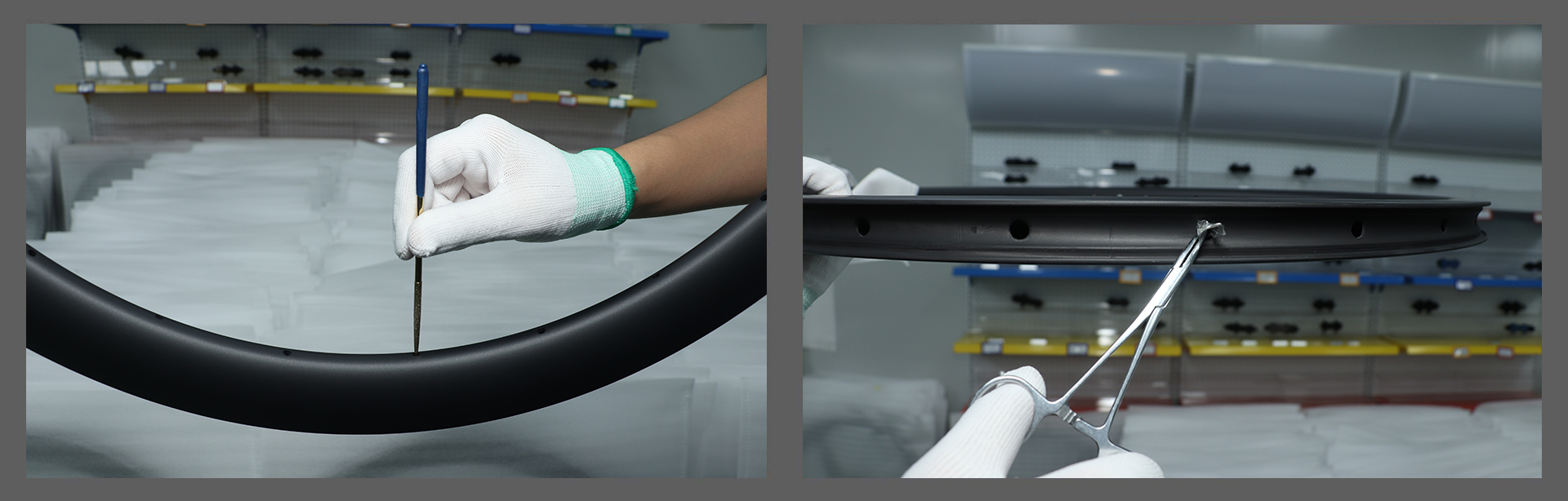

Strict Quality Control:

KOBIKE do 100% tire pressure(150 PSI), flatness(<0.2mm) and roundness(<0.2mm) inspections before shipping, also offering 2 years warranty for our carbon rims.

Aerodynamics and Adaptability:

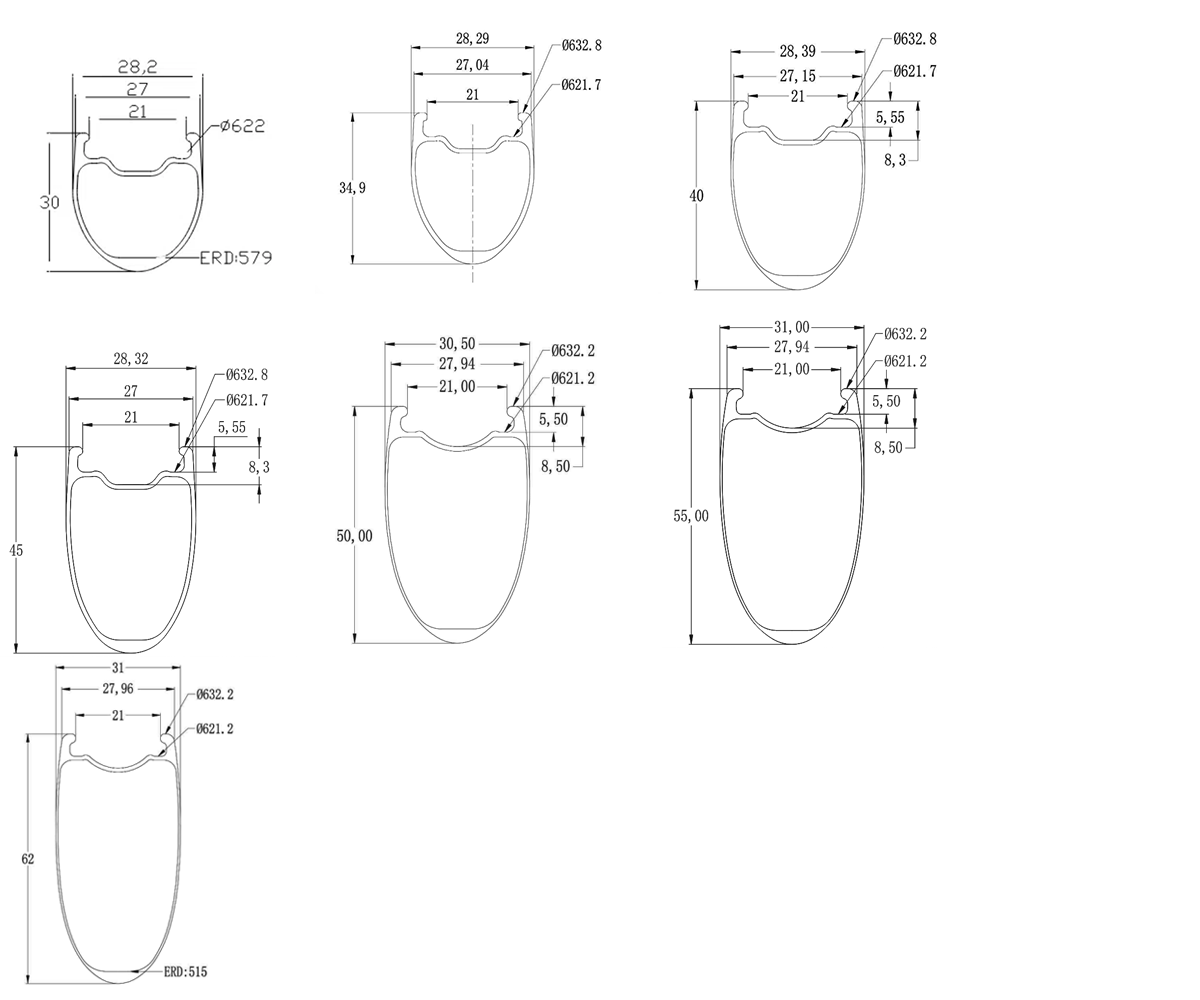

The 55mm rim is designed for high-speed cruising. Its 21mm internal width is compatible with tires ranging from 23-47cm, while its 31mm external width effectively balances wind resistance and grip. The D55X28TL-UL isn't a simplistic pursuit of extreme performance, but rather a sophisticated blend of mechanical efficiency, material intelligence, and ergonomic adaptability—achieving exceptional aerodynamics and adaptability, a truly "no-compromise" benchmark for modern road wheels.

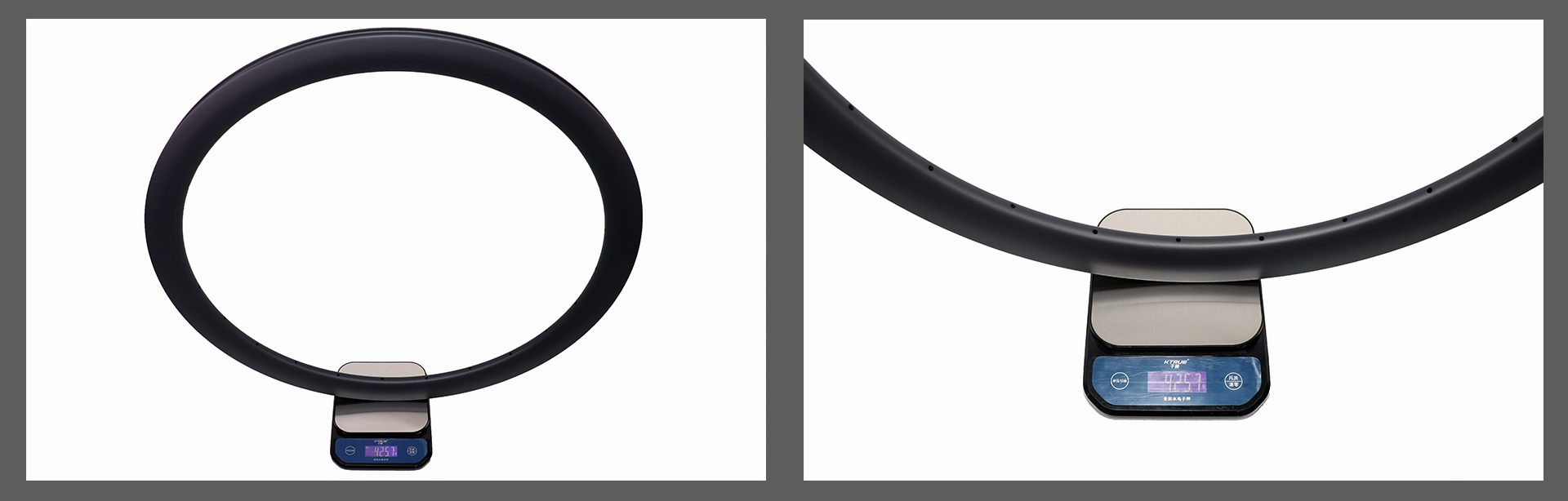

Lightweight and Durable:

The lightweight design, at 420±15g per lap, effectively reduces wheel loads. The 28mm-wide brake track eliminates brake heat from the rim. Furthermore, its durability is verified by 1,000 impact tests. The lightweight design allows for a more centralized center of gravity and enhanced agility, while the 1,000 impact tests ensure the rim's reliability under long-term use and intense riding.

Balancing Safety and Performance:

The 21mm internal width is compatible with tires 23–47mm wide and supports a maximum tire pressure of 120 psi, making it suitable for riders weighing 120 kg or less. This optimizes the tire's deformation trajectory under dynamic loads—creating a more even distribution of pre-tension on the sidewall during cornering and directional changes, reducing lag and improving maneuverability. It also enhances rim stability in various road conditions, achieving an optimal balance between safety and performance.

Application areas for the D55X28TL-UL carbon bicycle rim:

Road Racing:

The 55mm aerodynamic rim depth improves high-speed cruising performance, while the 28mm disc brake-specific brake track ensures stable braking, allowing riders to maintain speed in intense competition while ensuring safe braking, making it suitable for high-intensity competitive situations such as flat-road sprints.

Modular Basic Units in a Sustainable Cycling Ecosystem

Addressing the need for lifecycle management of cycling equipment, wide internal width rims extend the limits of tire use—a single pair of rims can accommodate a variety of tire sizes, from 28cm for racing to 45cm for endurance, reducing the resource consumption of purchasing multiple wheels for different scenarios. The 24mm internal width is gradually becoming a standardized interface for the "one bike, multiple uses" concept, driving the evolution of carbon wheels from "specialized tools" to "reconfigurable platforms."

Daily Training:

The lightweight design with a single-lap weight of 420±15g enhances riding flexibility, and the 1,000-cycle impact test ensures durability, meeting the needs of frequent daily training and adapting to varying training intensities.

Complex Surface Riding:

Supporting a maximum tire pressure of 120psi, suitable for riders weighing ≤120kg, it maintains rim stability and security on complex surfaces like gravel and rolling roads, providing reliable support.

Supporting Structure for Autonomous Navigation Cycling Experiences

Modern cycling increasingly relies on onboard sensors (such as power meters, tire pressure monitoring, and IMU attitude sensing). The 24mm internal width rims, with their more stable tire carcass, reduce minor wheel diameter changes caused by excessive tire wall deformation, thereby improving the accuracy of the underlying data used by speedometers, distance calculations, and navigation positioning, providing a more reliable physical foundation for smart cycling devices.

Model | Weight (Gram) | Brake System | Inner Width | Outer Width | Depth | Available Appearance | Available Spoke Hole Counts |

| R/D30X28TL-NL | 420/410±15g | Rim/Disc Brake | 21mm | 28mm | 30mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R/D30X28TL-SL | 400/390±15g | Rim/Disc Brake | 21mm | 28mm | 30mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| D30X28TL-UL | 305±15g | Disc Brake | 21mm | 28mm | 30mm | UD | 16/18/20/21/24/28/32/36H |

| R/D35X28TL-NL | 440/430±15g | Rim/Disc Brake | 21mm | 28mm | 35mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R/D35X28TL-SL | 420/410±15g | Rim/Disc Brake | 21mm | 28mm | 35mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| D35X28TL-UL | 320±15g | Disc Brake | 21mm | 28mm | 35mm | UD | 16/18/20/21/24/28/32/36H |

| R/D40X28TL-NL | 460/450±15g | Rim/Disc Brake | 21mm | 28mm | 40mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R/D40X28TL-SL | 440/430±15g | Rim/Disc Brake | 21mm | 28mm | 40mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| D40X28TL-UL | 340±15g | Disc Brake | 21mm | 28mm | 40mm | UD | 16/18/20/21/24/28/32/36H |

| R/D45X28TL-NL | 485/470±15g | Rim/Disc Brake | 21mm | 28mm | 45mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R/D45X28TL-SL | 465/450±15g | Rim/Disc Brake | 21mm | 28mm | 45mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| D45X28TL-UL | 360±15g | Disc Brake | 21mm | 28mm | 45mm | UD | 16/18/20/21/24/28/32/36H |

| R/D50X28TL-NL | 505/490±15g | Rim/Disc Brake | 21mm | 28mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R/D50X28TL-SL | 485/470±15g | Rim/Disc Brake | 21mm | 28mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| D50X28TL-UL | 385±15g | Disc Brake | 21mm | 28mm | 50mm | UD | 16/18/20/21/24/28/32/36H |

| D55X28TL-NL | 520±15g | Disc Brake | 21mm | 28mm | 55mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| D55X28TL-SL | 500±15g | Rim/Disc Brake | 21mm | 28mm | 55mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| D55X28TL-UL | 420±15g | Rim/Disc Brake | 21mm | 28mm | 55mm | UD | 16/18/20/21/24/28/32/36H |

| R/D62X28TL-NL | 550/540±15g | Rim/Disc Brake | 21mm | 28mm | 60mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R/D62X28TL-SL | 530/520±15g | Rim/Disc Brake | 21mm | 28mm | 60mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| D62X28TL-UL | 450±15g | Disc Brake | 21mm | 28mm | 60mm | UD | 16/18/20/21/24/28/32/36H |

100% Customizable

Customized Weaves & Finishes:

Customized Laser Engraving Brake Track:

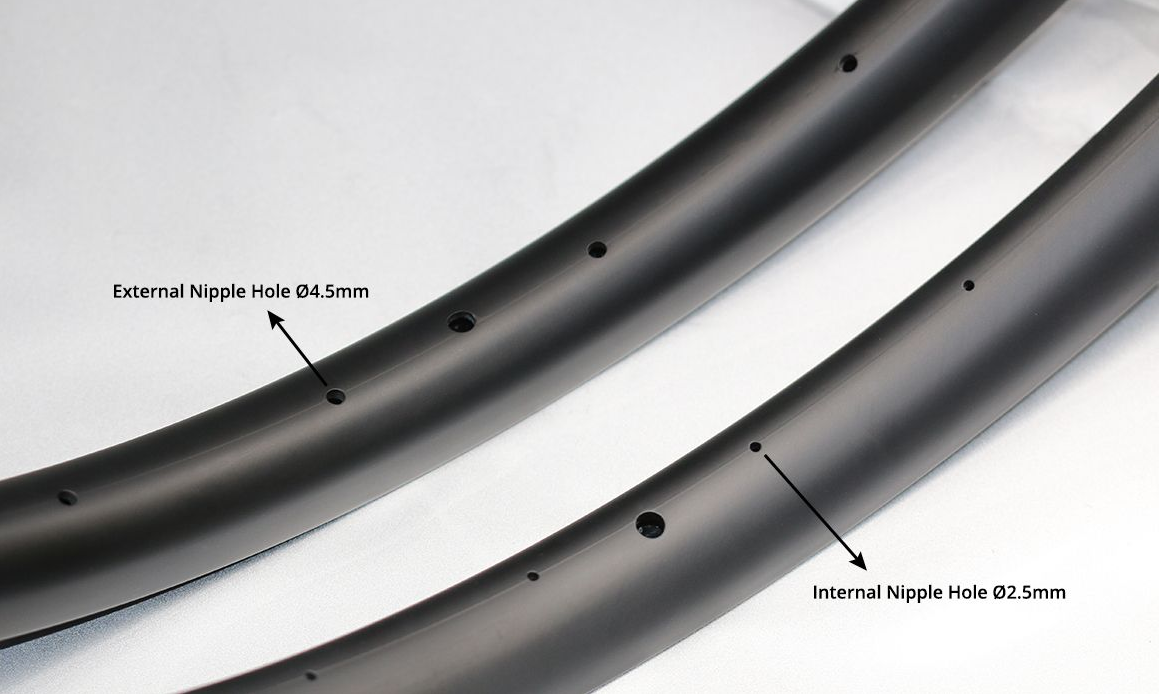

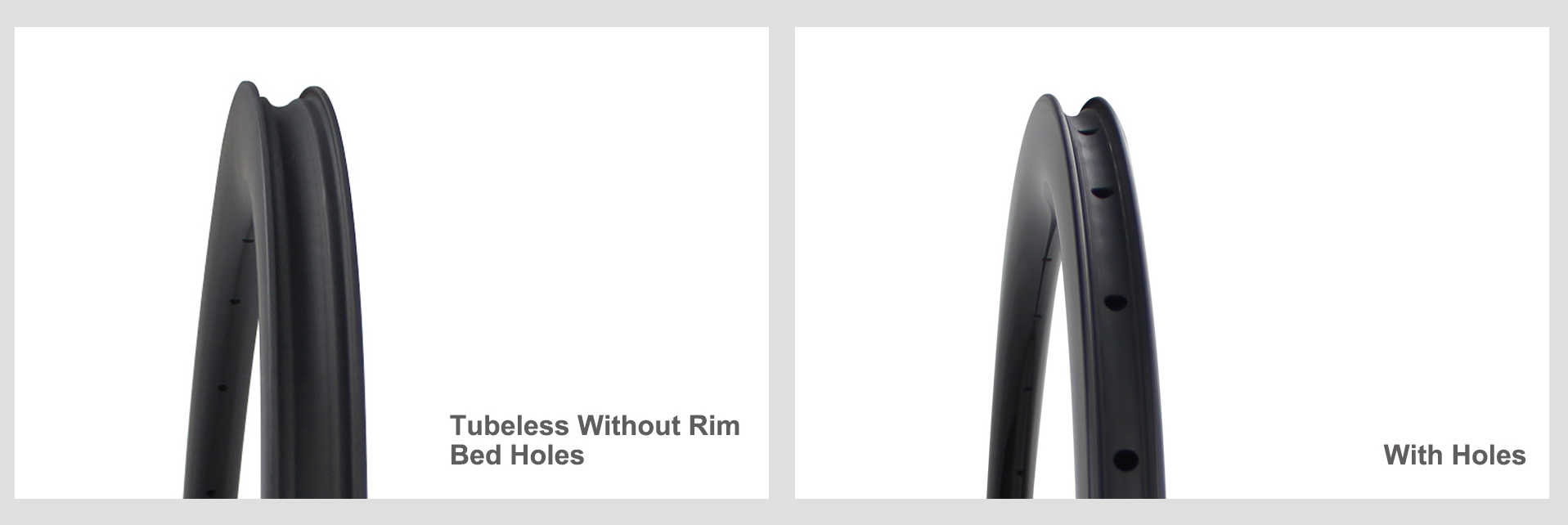

Customized Holes:

Weight Check:

Clean burrs & residues

Rim Diameters Check:

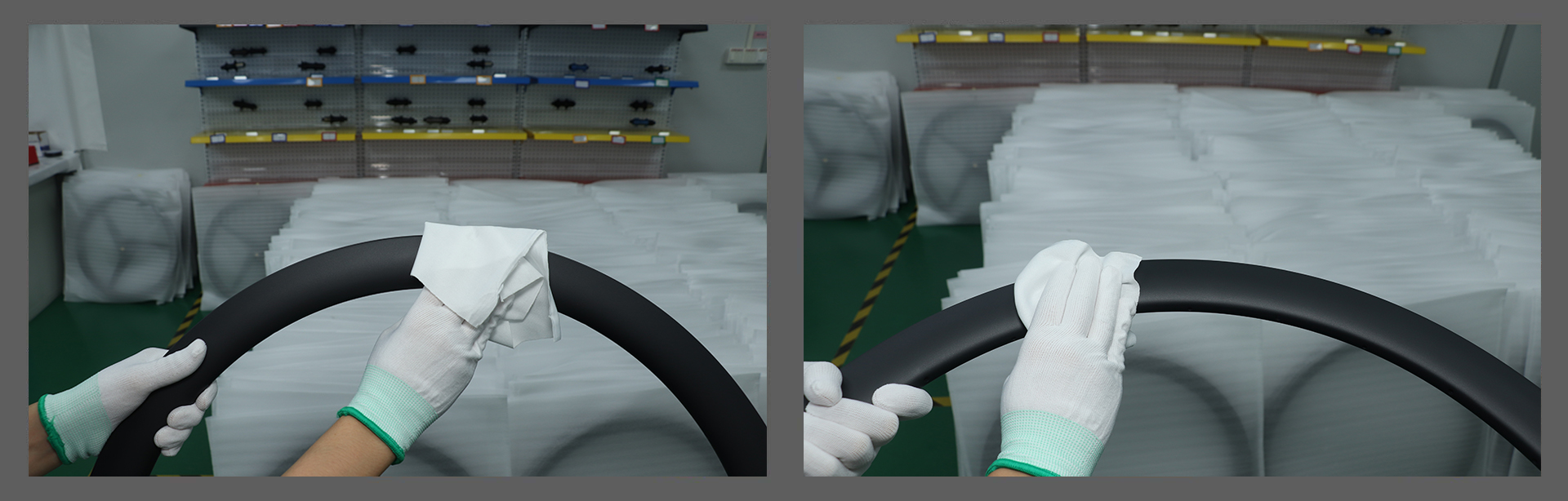

Cleaning & Packing

We have been in carbon bicycle production industry since the year of 2015, so 10 years history and experiences.

100 workers, 30 management, 20 Engineers, 10 Sales.

Carbon bicycle rims, carbon spokes, carbon wheels, cranks and other carbon bicycle components.

Our factory area is 2500 square meters, with 2 production lines, one wheel building line.

10.000 pcs/month for carbon rims, 100.000 pcs/month for carbon spokes, 10.000 pcs/month for other carbon bicycle components like cranks, handlebars, thru axles etc.

10-15 days for carbon rims(100-200 pcs), 7-10 days for carbon spokes, 25-30 days for carbon wheels.

It depend on the product models, quantities and and other factors, takes carbon rim for example, price generate from 80-130 USD per piece.

2 years for carbo rims and wheels, 1 year for carbon spokes.

We focus on OEM/ODM service for customers mainly on Europe and American markets.

We have signed confidential agreement with our big OEM customers, so not allow to tell, but the big brands from Europe and America.

Our factory locates in Xiamen, China.