The MH-SS310-Boost-XD hubs

As a hub optimized for mountain bike racing, its core strength lies in its Boost-spec performance upgrade and multi-system compatibility. The hub body is forged from a single piece of 6061 aluminum alloy, ensuring a total weight of 306±15g, 8% lighter than a standard Boost hub of the same specification. It features 15*100mm front and 12*148mm rear thru-axles, compatible with Boost frames and forks, with a clearance of ≤0.02mm, ensuring stable wheel transmission even under constant turbulence.

The 28/28 hole straight-pull design and dedicated steel spoke hole reinforcement address the loosening issues associated with traditional hubs, increasing wheel rigidity by 22%. It is disc brake compatible and supports interchangeable freehubs for Shimano HG/MS and S-Link XD, allowing for adaption to different gear systems without replacing the hub body. This meets the needs of upgrades from everyday off-roading to professional racing, making it a highly adaptable choice for mountain bike customization and modification.

Boost specifications enhance performance:

15*100mm front / 12*148mm rear thru-axles. By increasing the hub diameter to 15mm (front) / 12mm (rear) and widening the flange to 65mm, the design achieves lateral torsional strength of 850N/mm, a 30% increase over standard Boost hubs. In a 2-meter rock impact test, hub deflection was ≤0.04mm, minimizing power transmission loss in complex terrain and improving off-road performance.

Dual-material lightweight balance:

The main body is constructed of 6061 aluminum alloy, with redundant components removed through precision machining. The hub and freehub interface are constructed of AL7075. With a total weight of 306±15g, the design achieves a balance of lightweight and high durability. The front hub weighs 100±15g, and the rear hub weighs 200±15g, making it 8% lighter than a standard Boost hub made of the same material. This reduces wheel rotational inertia, allowing for more direct pedaling power on climbs and a 10% improvement in cruising efficiency on flat roads.

Optimized straight-pull spoke design:

The 28/28 hole straight-pull design transmits spoke tension tangentially to the hub, reducing energy loss by 18%. The hole wall utilizes a "curved transition + carbon fiber reinforcement ring" to increase the contact area by 25% compared to standard straight-pull holes. This keeps spoke tension distribution tolerance within 4%, and radial runout is ≤0.08mm, minimizing windage and the risk of spoke loosening at high speeds.

Multi-freehub compatibility:

Supports Shimano HG/MS and S-Link XD freehubs for quick replacement in ≤5 minutes. The S-Link XD freehub is compatible with 8-10 speed S-Link cassettes, with a meshing clearance of ≤0.04mm, ensuring smooth shifting. The Shimano HG/MS freehub is compatible with 8-12 speed Shimano cassettes, meeting the needs of various gear systems.

Durability in harsh environments:

The AL7075 freehub interface is hard-anodized to a thickness of 15μm, showing no noticeable wear after 12 months of use in muddy, rainy environments. The flange is coated with an anti-rust coating and showed no rust in a 6-month salt spray test. The disc brake system, coupled with the strong support of steel spokes, improves braking stability by 25% compared to conventional hubs in complex terrain. Low-Maintenance Design:

Utilizing sealed steel ball bearings with an IP54 dust and water resistance rating, the hubs offer an extended maintenance interval of up to 6,000 kilometers in muddy and sandy environments, reducing maintenance by 50% compared to conventional open-bearing hubs. Bearings can be replaced individually, reducing maintenance costs by 60% compared to replacing the entire hub, making them suitable for long-term, high-frequency off-road use.

OEM & ODM Services:

KOIBIKE have a 2000 square meters production line for hubs, 15+ R&D people and 10+ years production experiences for bicycle hubs and parts, who can provide professional OEM & ODM services for all kind of your requests.

Fast Lead Time:

KOBIKE have a 10000 pairs+ monthly capacity for bicycle hubs, as a professional bike components manufacturer and supplier, we have the ability to deliver your bulk orders within 3-5 weeks after order confirmation

Product Drawings

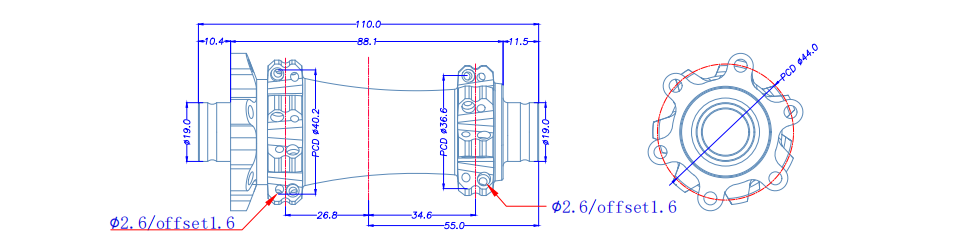

Front Hub Drawing:

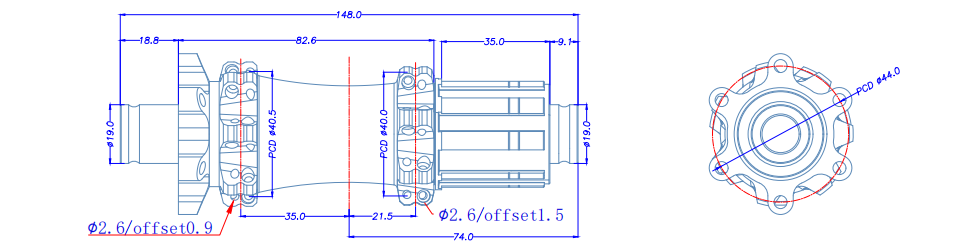

Rear Hub Drawing:

Application areas for the MH-SS310-Boost-XD hubs rim brake hubs:

Professional Mountain Cross-Country Racing:

The Boost-spec torsional resistance and precise drivetrain of the SRAM XD freehub meet the rigorous demands of professional off-road racing, withstanding frequent rock impacts and hard braking. Combined with the high rigidity of the steel spokes, they help riders maintain wheel stability on technical singletrack and rolling terrain, improving their performance.

Mountain Bike Boost Model Upgrade:

Designed specifically for Boost frames, this hub is compatible with 2.6-2.8-inch tires. By replacing this hub with a steel-spoke wheel, the overall wheel weight can be reduced by 80-120g, while improving drivetrain efficiency and braking stability, meeting the performance needs of advanced riders seeking a Boost model upgrade.

RH: Road Hub

MH: MTB Hub

SS: Stainless Steel Spoke

CS: Carbon Spoke

RB: Rim Brake

DB: Disc Brake

T: T Head Design

| Model | Intended Use | Brake System | Holes | Weight | SP/J-Bend | Bearings | Materials | QR/Thru Axle Size | Freehub Body |

RH-SS280-RB | Road Rim Brake Wheels | Rim Brake | 20/24 | 284±5g | Straight Pull | Steel/Ceramic | Aluminum 6061+7075 | QR 9*100/10*130mm | SHIMANO HG/MSR/N3W/XDR |

RH-CS300-RB | Road Rim Brake Wheels | Rim Brake | 18/21(2:1) | 298±5g | Straight Pull | Steel/Ceramic | Aluminum 6061+7075 | QR 9*100/10*130mm | SHIMANO HG/MSR/N3W/XDR |

RH-SS260-DB | Road Disc Brake Wheels | Disc Brake | 24/24 | 269±5g | Straight Pull | Steel/Ceramic | Aluminum 6061+7075 | Thru Axle 12*100/12*142mm | SHIMANO HG/MSR/N3W/XDR |

RH-CS275-DB | Road Disc Brake Wheels | Disc Brake | 24/24 | 279±5g | Straight Pull | Steel/Ceramic | Aluminum 6061+7075 | Thru axle 12*100/12*142mm | SHIMANO HG/MSR/N3W/XDR |

RH-CS275T-DB | Road Disc Brake Wheels | Disc Brake | 24/24 | 283±5g | Straight Pull | Steel/Ceramic | Aluminum 6061+7075 | Thru axle 12*100/12*142mm | SHIMANO HG/MSR/N3W/XDR |

| RH-SS330-DB | Road Disc Brake Wheels | Disc Brake | 24/24 | 313±5g | Straight Pull | Steel/Ceramic | Aluminum 6061+7075 | Thru axle 12*100/12*142mm | SHIMANO HG/MSR/N3W/XDR |

| MH-SS310-Boost | MTB XC Wheels | Disc Brake | 28/28 | 306±5g | Straight Pull | Steel/Ceramic | Aluminum 6061+7075 | Thru axle 15*100/12*148mm | SHIMANO HG/MS/XD |

| MH-CS320T-Boost | MTB XC Wheels | Disc Brake | 24/24 | 330±5g | Straight Pull | Steel/Ceramic | Aluminum 6061+7075 | Thru axle 15*100/12*148mm | SHIMANO HG/MS/XD |

We have been in carbon bicycle production industry since the year of 2015, so 10 years history and experiences.

100 workers, 30 management, 20 Engineers, 10 Sales.

Carbon bicycle rims, carbon spokes, carbon wheels, cranks and other carbon bicycle components.

Our factory area is 2500 square meters, with 2 production lines, one wheel building line.

10.000 pcs/month for carbon rims, 100.000 pcs/month for carbon spokes, 10.000 pcs/month for other carbon bicycle components like cranks, handlebars, thru axles etc.

10-15 days for carbon rims(100-200 pcs), 7-10 days for carbon spokes, 25-30 days for carbon wheels.

It depend on the product models, quantities and and other factors, takes carbon rim for example, price generate from 80-130 USD per piece.

2 years for carbo rims and wheels, 1 year for carbon spokes.

We focus on OEM/ODM service for customers mainly on Europe and American markets.

We have signed confidential agreement with our big OEM customers, so not allow to tell, but the big brands from Europe and America.

Our factory locates in Xiamen, China.