This mountain bike rim is crafted from high - quality carbon fiber, ensuring an exceptional combination of lightweight performance and durability, making it ideal for off - road adventures. As a factory - direct supply product, we eliminate middlemen, enabling us to offer competitive prices while guaranteeing product quality.

We take pride in our 10 years of industry experience, which has equipped us with profound expertise in carbon fiber rim production. This rich experience allows us to maintain strict quality control throughout the manufacturing process, from material selection to the final product inspection.

Personalized customization is one of our key strengths. We offer a wide range of customization options, including carbon fiber textures (such as 3K twill and UD unidirectional patterns), spoke hole quantities (28 - 36 holes to meet different riding needs), and rim decals (laser - engraved for a unique touch). This ensures that each rim can be tailored to the specific requirements of our customers.

Moreover, we specialize in B2B services, catering to the needs of bicycle manufacturers, distributors, and professional teams. Our efficient production capacity and flexible supply chain management enable us to handle bulk orders smoothly, providing reliable and timely deliveries to our business partners.

Premium Material Performance:

Crafted from high-quality carbon fiber, the rim achieves an excellent balance between lightweight and durability. Each rim weighs only 265-345g, which is significantly lighter than traditional aluminum alloy rims, reducing the overall weight of the bike and making it more agile during off-road rides. At the same time, carbon fiber's inherent strength ensures strong impact resistance, capable of withstanding the bumps and shocks of rough terrains.

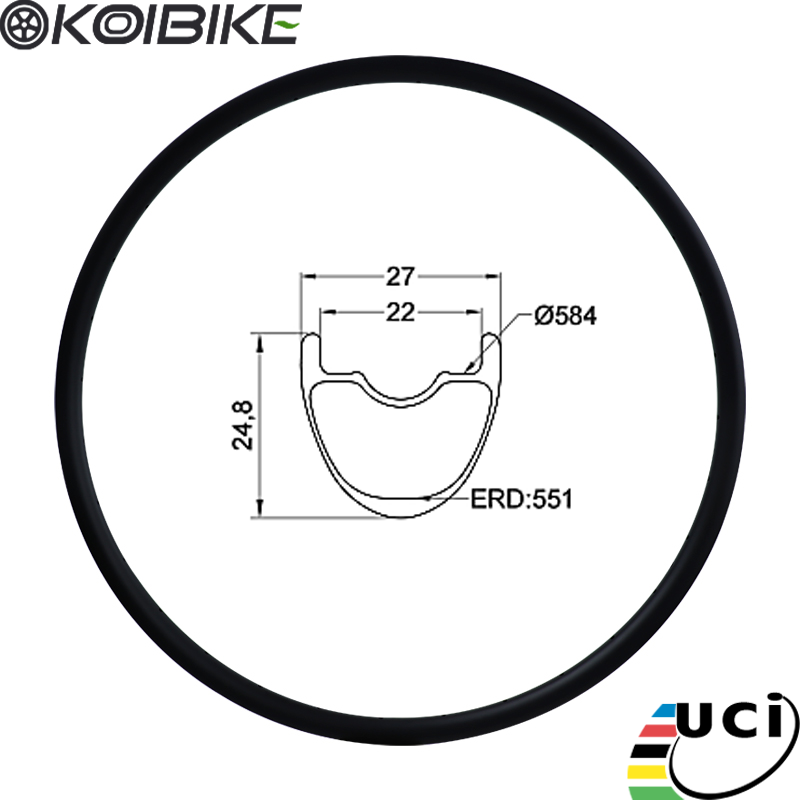

Optimal Size Design:

With a height of 25mm and an outer width of 27mm, this rim is meticulously engineered for off-road use. The 25mm height provides sufficient lateral stiffness, ensuring stable performance when cornering and handling, while the 27mm outer width offers ample support for tires ranging from 21.8" to 2.2". This width not only enhances the tire's contact area with the ground, improving grip, but also helps maintain tire shape under various pressures, suitable for different off-road conditions.

Straight-Edge Design:

Adopting a straight-edge design, the rim brings multiple benefits. It simplifies the tire installation process, especially when using vacuum tires, ensuring a tighter seal between the tire and the rim. Additionally, this design reduces unnecessary weight compared to traditional hooked rims, further contributing to the overall lightweight of the wheel, and enhances the rim's structural integrity to better resist deformation.

Factory-Direct Advantage:

As a factory-direct supply product, it cuts out middlemen, allowing for more competitive pricing. Meanwhile, direct control from production to sales ensures strict quality supervision, with each rim undergoing rigorous testing such as tension tests and impact resistance tests, providing customers with reliable products.

Extensive Customization Options:

Personalized customization is a standout feature. Customers can choose from various carbon fiber textures (like 3K twill and UD unidirectional patterns) to achieve a unique visual effect. They can also select spoke hole quantities (28-36 holes) based on different riding styles and terrain requirements – fewer holes for lighter weight in XC racing, more holes for enhanced strength in AM all-terrain riding. Moreover, laser-engraved rim decals are available to meet brand or personal logo needs, ensuring the product perfectly matches individual requirements.

Solid Production Expertise:

With 10 years of industry experience, the factory has profound expertise in carbon fiber rim production. This experience guarantees strict quality control throughout the manufacturing process, from the selection of high-grade carbon fiber materials to the precise molding and curing processes, and finally to the detailed inspection of each finished product, ensuring consistent product quality.

Professional B2B Capabilities:

Specializing in B2B services, the factory is well-equipped to meet the needs of bicycle manufacturers, distributors, and professional teams. Its efficient production capacity, with a monthly output of up to a large quantity, and flexible supply chain management enable smooth handling of bulk orders, ensuring reliable and timely deliveries, which is a significant advantage for business partners.

Vacuum Tire Compatibility:

The rim is designed to be compatible with vacuum tires, eliminating the need for inner tubes. This not only reduces the risk of punctures caused by pinch flats during off-road rides but also improves rolling efficiency as there's no friction between the inner tube and the tire. Additionally, it allows for lower tire pressures, enhancing traction on loose or uneven surfaces, thus improving the overall riding experience.

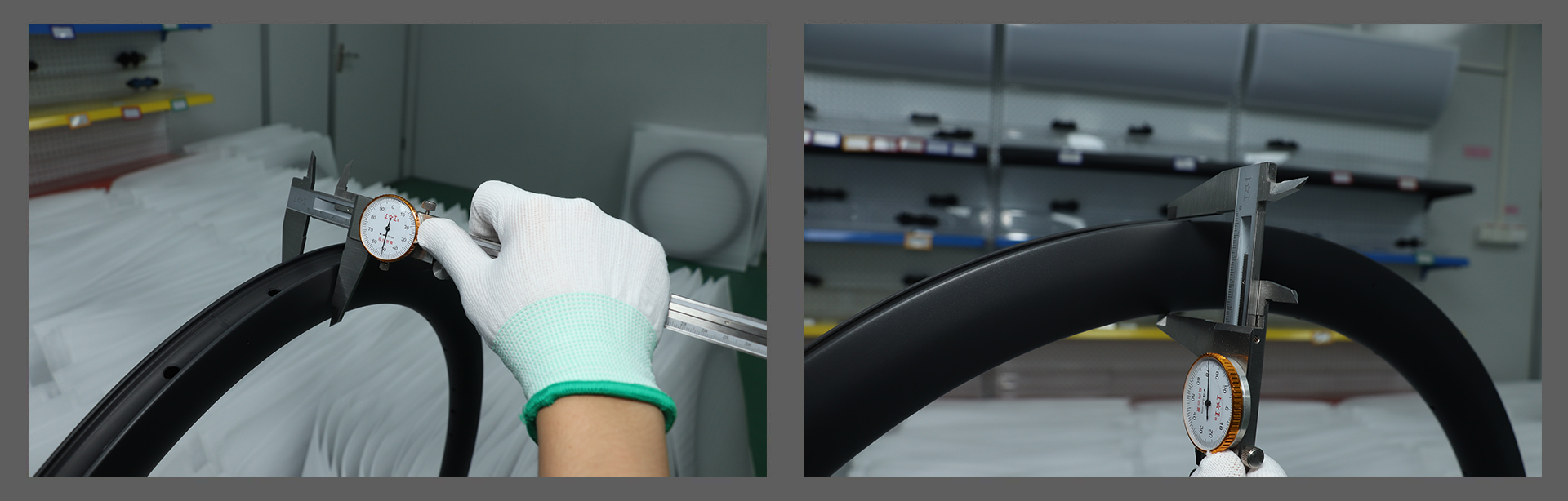

Strict Quality Control:

KOBIKE do 100% tire pressure(150 PSI), flatness(<0.2mm) and roundness(<0.2mm) inspections before shipping, also offering 2 years warranty for our carbon rims.

Integrated Carbon Fiber Construction:

The rim features a one-piece molded structure using high-quality carbon fiber materials. This integrated design eliminates weak points that might exist in assembled structures, enhancing overall structural rigidity and reducing the risk of failure under heavy loads during off-road rides.

Layered Carbon Fiber Arrangement:

The carbon fiber layers are strategically arranged to optimize performance. Multiple layers of carbon fiber cloth with different orientations (such as 0°, 45°, and 90°) are laminated together. The 0° layers primarily provide longitudinal strength for withstanding tension from spokes, while the 45° and 90° layers enhance lateral stiffness and impact resistance, ensuring the rim can handle the twists and impacts of rough terrains.

Reinforced Spoke Hole Zones:

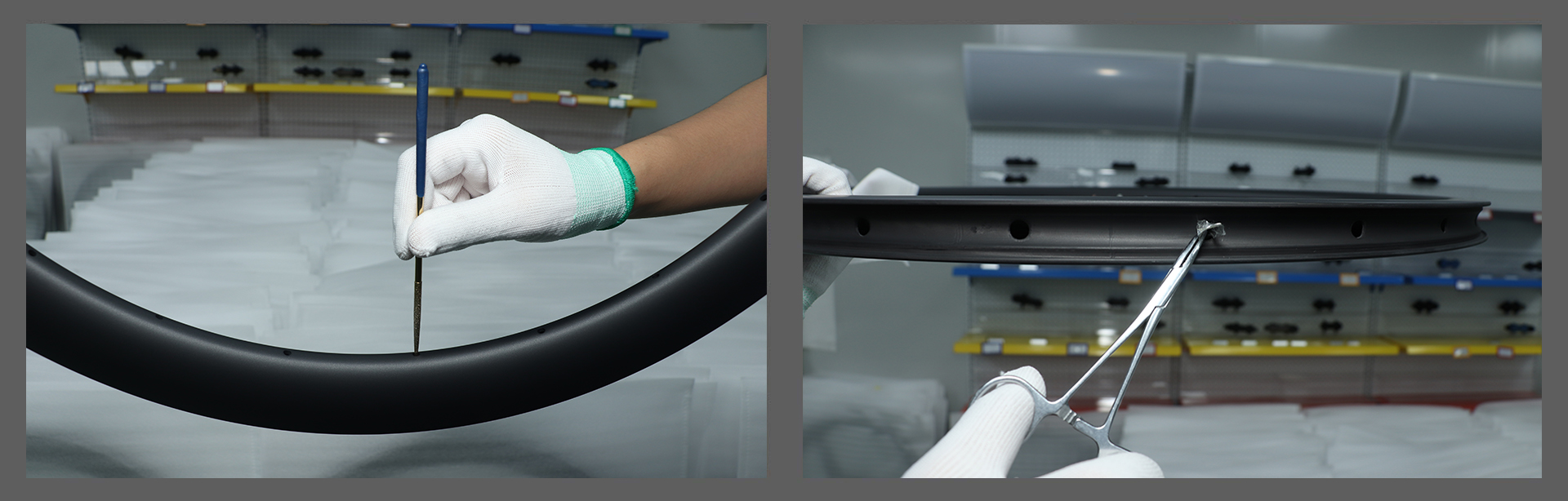

The areas around the spoke holes are specially reinforced. Extra layers of carbon fiber are added here to distribute the tension from the spokes evenly, preventing stress concentration that could lead to cracking. The holes are precisely drilled with smooth edges to further reduce the risk of damage.

Straight - Edge Profile Design:

The straight - edge design not only simplifies tire installation but also contributes to the structural integrity. The smooth, continuous edge distributes forces more evenly when the tire is inflated or when the rim encounters obstacles, reducing the likelihood of deformation compared to rims with complex hooked edges.

Controlled Wall Thickness:

The wall thickness of the rim is carefully controlled during the manufacturing process. It is thicker in areas that bear more stress, such as the bead seat and the central part of the rim, to provide sufficient strength. In less stressed areas, the thickness is optimized to reduce weight, achieving a balance between strength and lightweight.

Application areas for the XC-MA22X30HL carbon bicycle rim:

Cross-Country (XC) Racing:

The lightweight nature of the carbon fiber construction (265-345g) and optimized structural design make this rim ideal for XC racing. Its integrated one-piece molding and layered carbon fiber arrangement ensure sufficient rigidity to handle the ups and downs of cross-country trails, while the controlled wall thickness keeps the weight in check, allowing riders to accelerate quickly and climb efficiently.

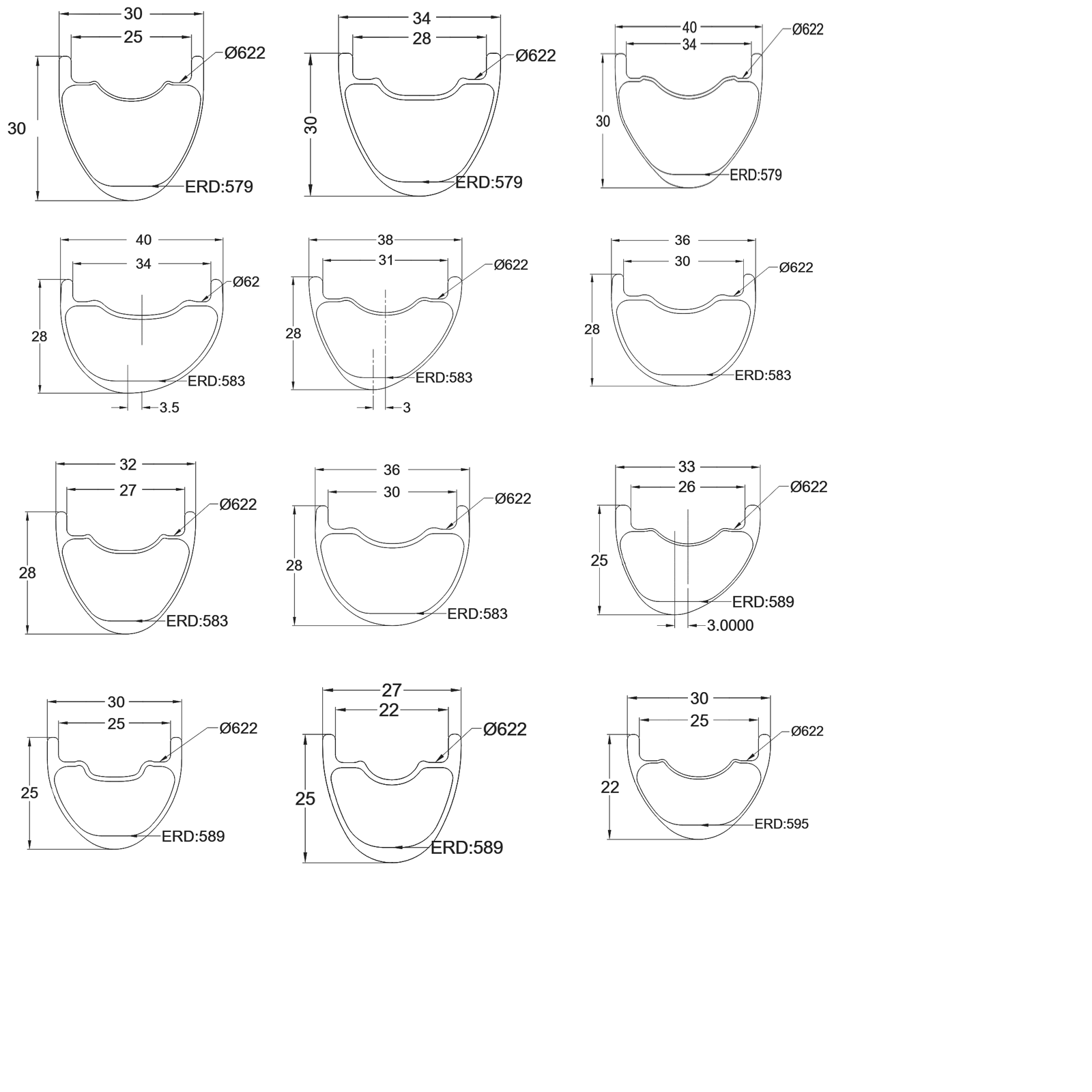

| Model | Weight (Gram) | Inner Width | Outer Width | Depth | Brake System | Available Appearance | Available Spoke Hole Counts |

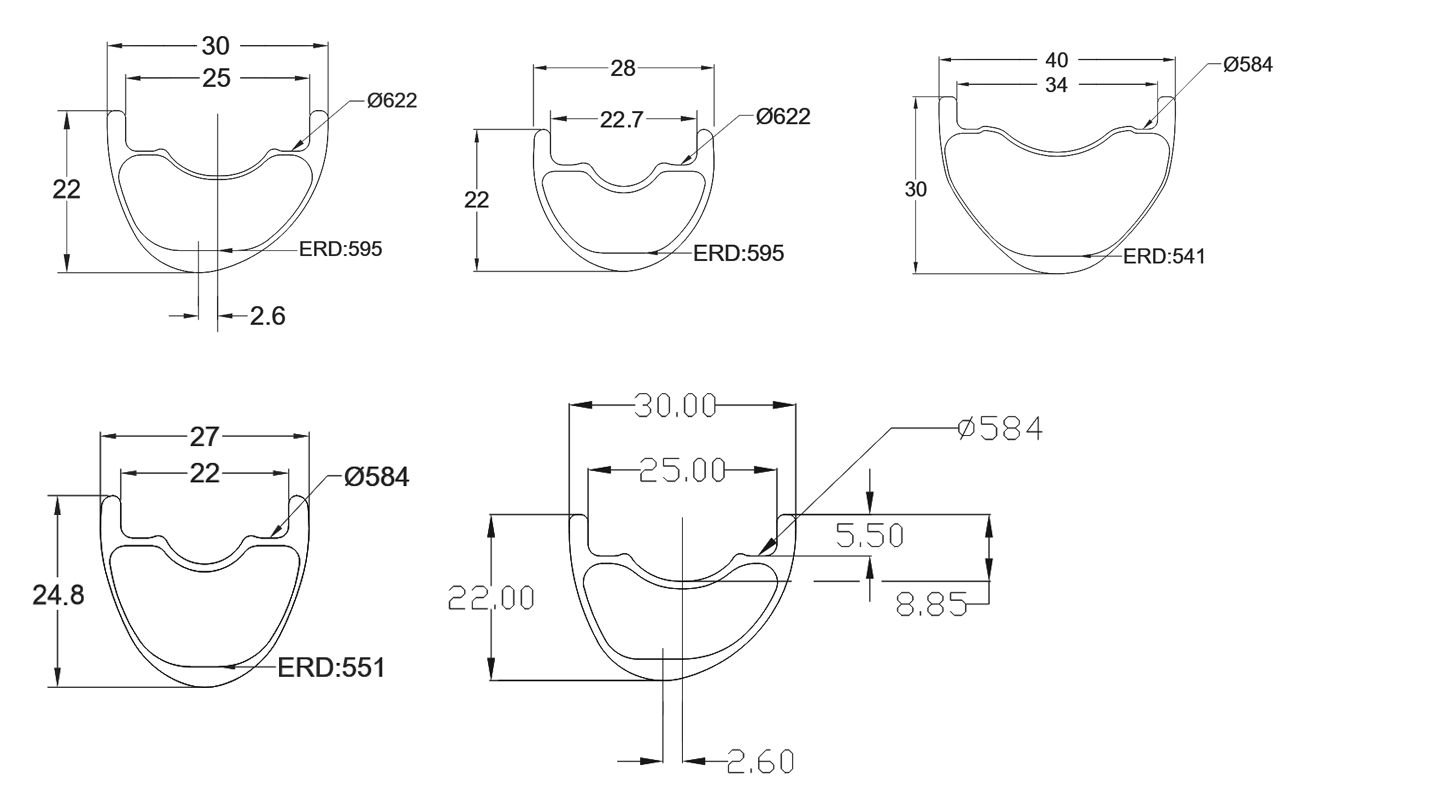

| XC-M25X27HL-27.5-SL | 345±15 | 22mm | 27mm | 24.8mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-M25X27HL-27.5-UL | 265±15 | 22mm | 27mm | 24.8mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-MA22X30HL-27.5-SL | 345±15 | 25mm | 30mm | 22mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-MA22X30HL-27.5-UL | 295±15 | 25mm | 30mm | 22mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| AM-MA25X33HL-27.5-SL | 360±15 | 26mm | 33mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-MA25X33HL-27.5-UL | 320±15 | 26mm | 33mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| EN-M30X40HL-27.5-SL | 460±15 | 34mm | 40mm | 30mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| AM-M30X40HL-27.5-UL | 420±15 | 34mm | 40mm | 30mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-M22X28HL-29ER-UL | 300±15 | 22.7mm | 28mm | 22mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-MA22X30HL-29ER-NL | 360±15 | 25mm | 30mm | 22mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-MA22X30HL-29ER-SL | 310±15 | 25mm | 30mm | 22mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-MA22X30HL-29ER-UL | 255±15 | 25mm | 30mm | 22mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| XC-M22X30HL-29ER-NL | 360±15 | 25mm | 30mm | 22mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-M22X30HL-29ER-SL | 310±15 | 25mm | 30mm | 22mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-M22X30HL-29ER-UL | 255±15 | 25mm | 30mm | 22mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| XC-M25X27HL-29ER-SL | 370±15 | 22mm | 27mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-M25X27HL-29ER-UL | 285±15 | 22mm | 27mm | 25mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| XC-M20X36HL-29ER | 285±15 | 30mm | 36mm | 20mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| XC-M25X30HL-29ER-NL | 360±15 | 25mm | 30mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-M25X30HL-29ER-SL | 310±15 | 25mm | 30mm | 25mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| XC-M25X30HL-29ER-UL | 260±15 | 25mm | 30mm | 25mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| AM-MA25X33HL-29ER | 400±15 | 26mm | 33mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| TR-MA25X33HL-29ER | 380±15 | 26mm | 33mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-MA25X33HL-29ER | 340±15 | 26mm | 33mm | 25mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| AM-M25X35HL-29ER | 385±15 | 28mm | 35mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-MA25X35HL-29ER-NL | 360±15 | 30mm | 35mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-MA25X35HL-29ER-SL | 320±15 | 30mm | 35mm | 25mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| XC-MA25X35HL-29ER-UL | 280±15 | 30mm | 35mm | 25mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| XC-MA25X33HL-29ER-SL | 380±15 | 27mm | 32mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-MA25X33HL-29ER-UL | 330±15 | 27mm | 32mm | 25mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| AM-M22X30HL-29ER-SL | 435±15 | 25mm | 30mm | 22mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-M22X30HL-29ER-UL | 360±15 | 25mm | 30mm | 22mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| EN-MA28X38HL-29ER-SL | 490±15 | 31mm | 38mm | 28mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| AM-MA28X38HL-29ER-UL | 450±15 | 31mm | 38mm | 28mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| EN-MA28X40HL-29ER-SL | 490±15 | 34mm | 40mm | 28mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| AM-MA28X40HL-29ER-UL | 460±15 | 34mm | 40mm | 28mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-M30X30HL-29ER-SL | 380±15 | 25mm | 30mm | 30mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-M30X30HL-29ER-UL | 345±15 | 25mm | 30mm | 30mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| AM-M30X34HL-29ER-SL | 435±15 | 28mm | 34mm | 30mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-M30X34HL-29ER-UL | 350±15 | 28mm | 34mm | 30mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| EN-M30X40HL-29ER-SL | 480±15 | 34mm | 40mm | 30mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| AM-M30X40HL-29ER-UL | 440±15 | 34mm | 40mm | 30mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

100% Customizable

Customized Weaves & Finishes:

Customized Holes:

![]()

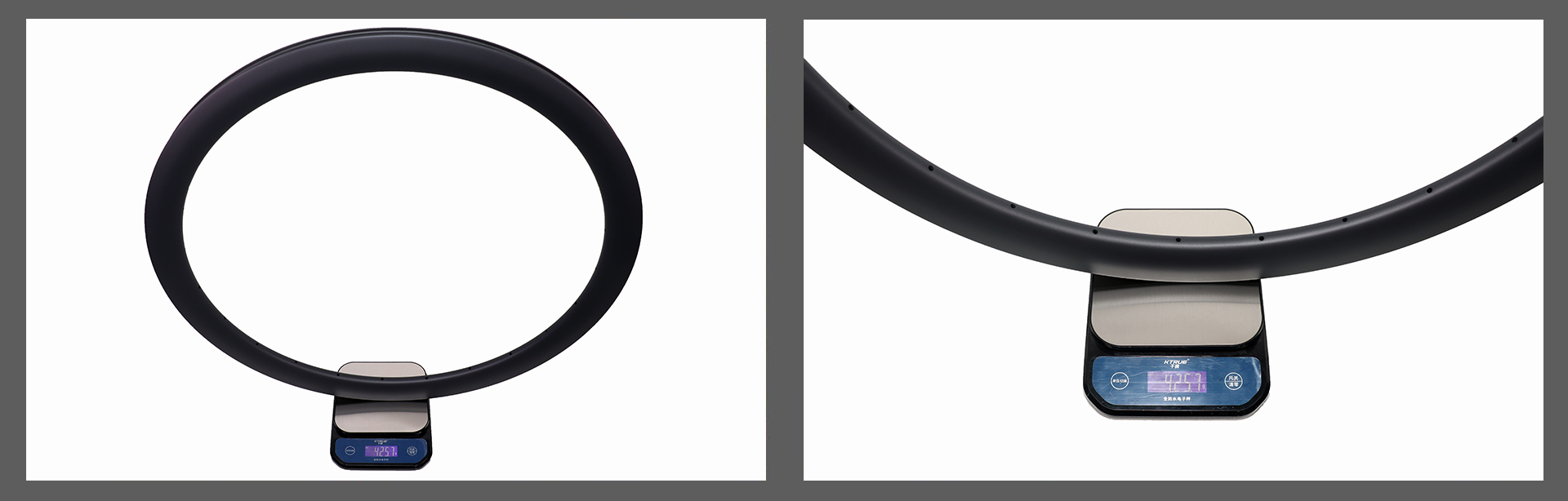

Weight Check:

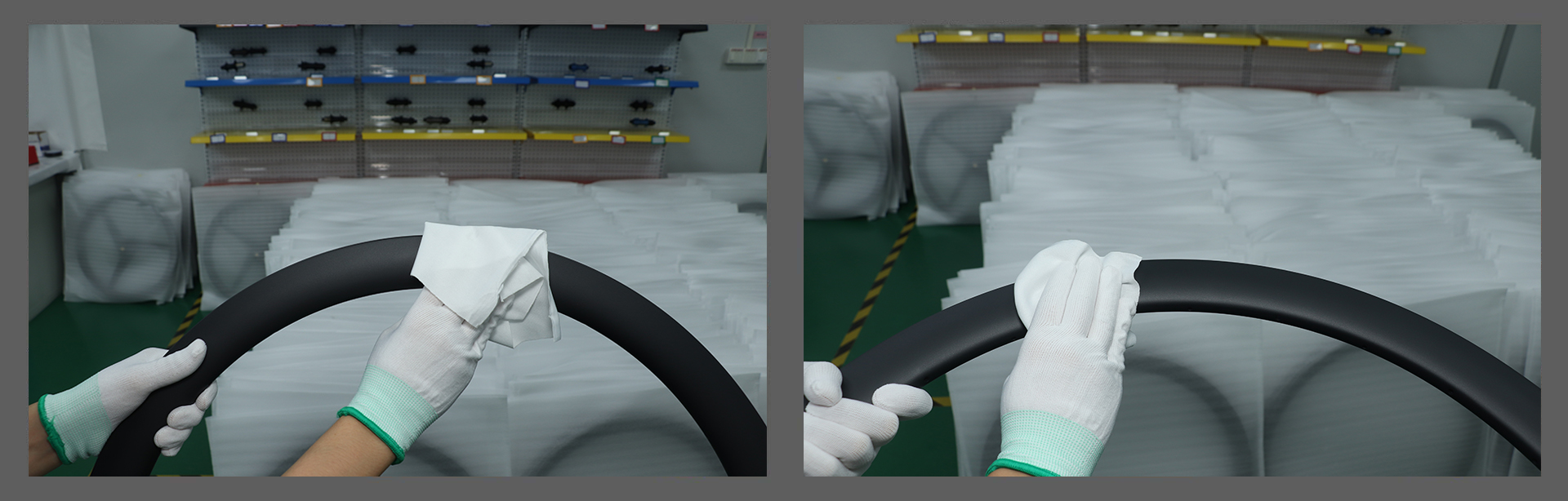

Clean burrs & residues:

Rim Diameters Check:

Cleaning:

Packing:

We have been in carbon bicycle production industry since the year of 2015, so 10 years history and experiences.

100 workers, 30 management, 20 Engineers, 10 Sales.

Carbon bicycle rims, carbon spokes, carbon wheels, cranks and other carbon bicycle components.

Our factory area is 2500 square meters, with 2 production lines, one wheel building line.

10.000 pcs/month for carbon rims, 100.000 pcs/month for carbon spokes, 10.000 pcs/month for other carbon bicycle components like cranks, handlebars, thru axles etc.

10-15 days for carbon rims(100-200 pcs), 7-10 days for carbon spokes, 25-30 days for carbon wheels.

It depend on the product models, quantities and and other factors, takes carbon rim for example, price generate from 80-130 USD per piece.

2 years for carbo rims and wheels, 1 year for carbon spokes.

We focus on OEM/ODM service for customers mainly on Europe and American markets.

We have signed confidential agreement with our big OEM customers, so not allow to tell, but the big brands from Europe and America.

Our factory locates in Xiamen, China.