With the growing demand for lightweight, aerodynamic, and versatile road bikes, the D50X30TL/HL-UL is the ideal choice for riders seeking extreme performance. Its rim design effectively reduces wind resistance, improves cruising efficiency, and enhances grip and comfort. The straight-rim version is designed for tubeless tyres, while the hook-rim version is compatible with both tubeless and clincher tyres. Each rim weighs just 400g ± 15g. This wheel is independently developed and manufactured by KOIBIKE. Leveraging ten years of experience in carbon fiber wheel manufacturing and a robust supply chain within its own factory, KOIBIKE can efficiently meet the bulk purchasing and customization needs of B2B customers.

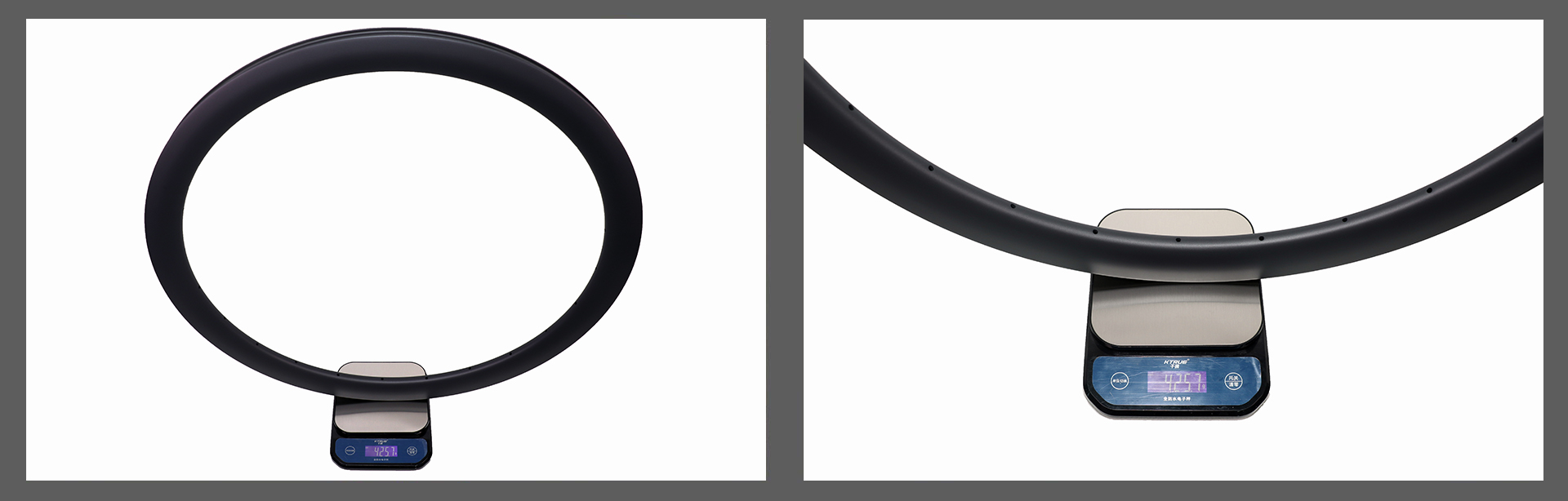

Ultra-lightweight design:

Each rim weighs just 400g ± 15g, reducing rotational resistance and improving acceleration and climbing efficiency.

Compatible with a variety of spoke shapes:

round, oval, tapered, flat, and carbon.

Wide tire compatibility:

The 24mm internal width accommodates tires 28–50c. The straight-sided version is tubeless-ready, while the hook-sided version is compatible with both tubeless and clincher tires, meeting diverse usage scenarios.

High rigidity and durability:

Utilizing Japanese Toray T700 to T1100 carbon fibers, cured by high-temperature lamination, they provide excellent resistance to torsional and deformation.

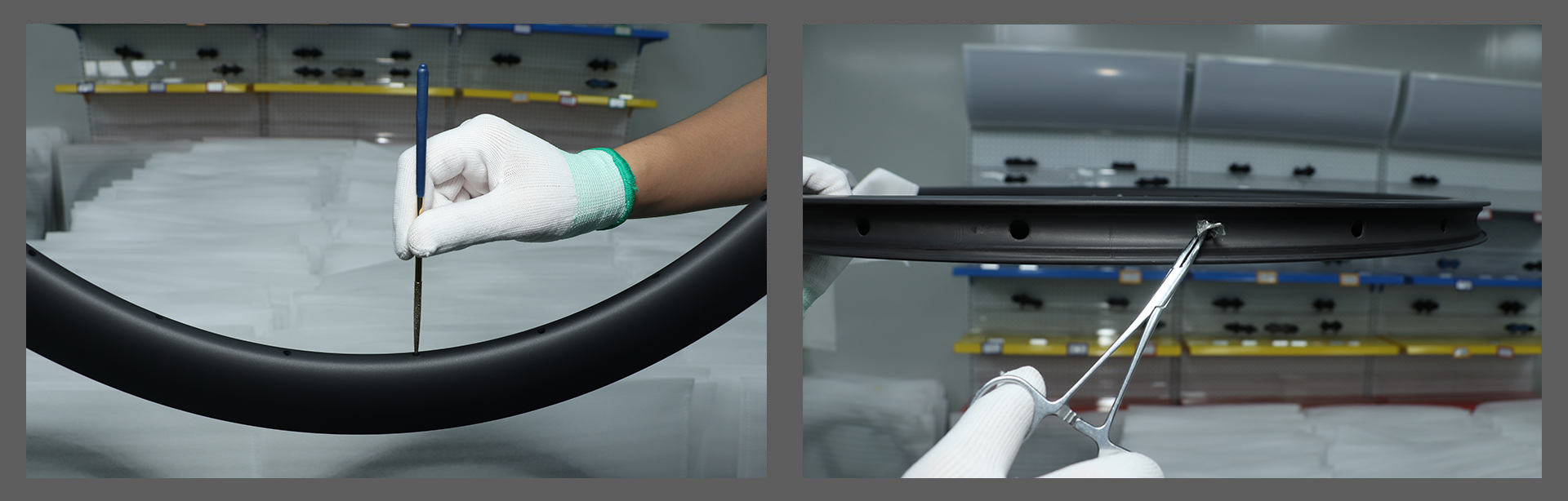

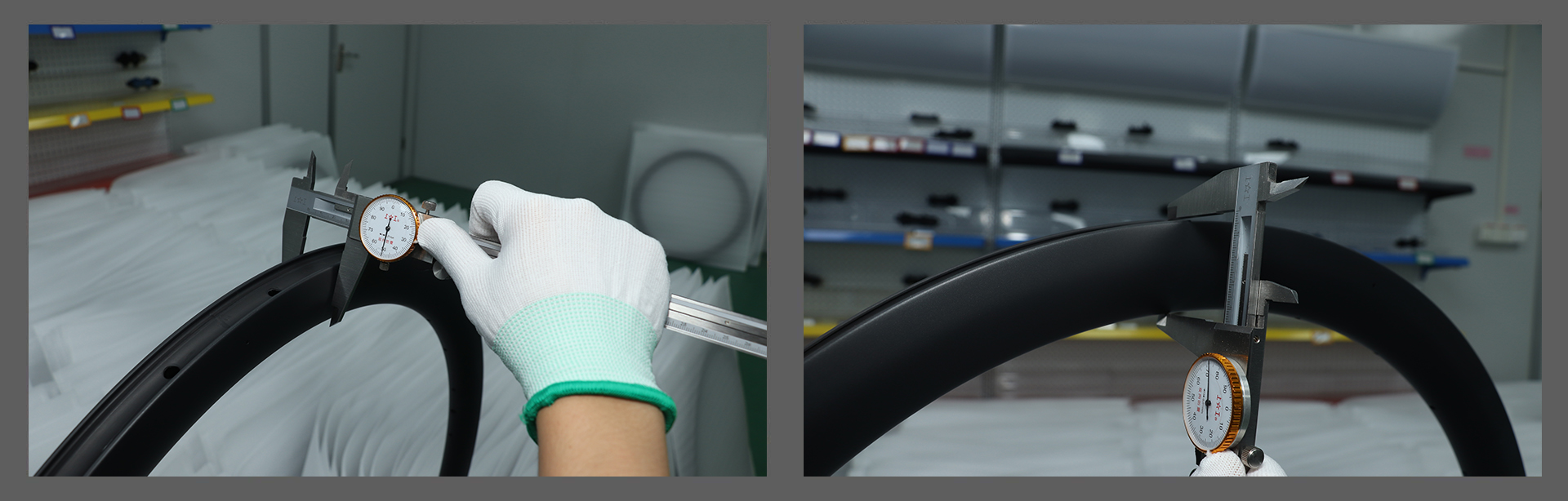

Strict Quality Control:

KOBIKE do 100% tire pressure(150 PSI), flatness(<0.2mm) and roundness(<0.2mm) inspections before shipping, also offering 2 years warranty for our carbon rims.

Rim Height and Usage:

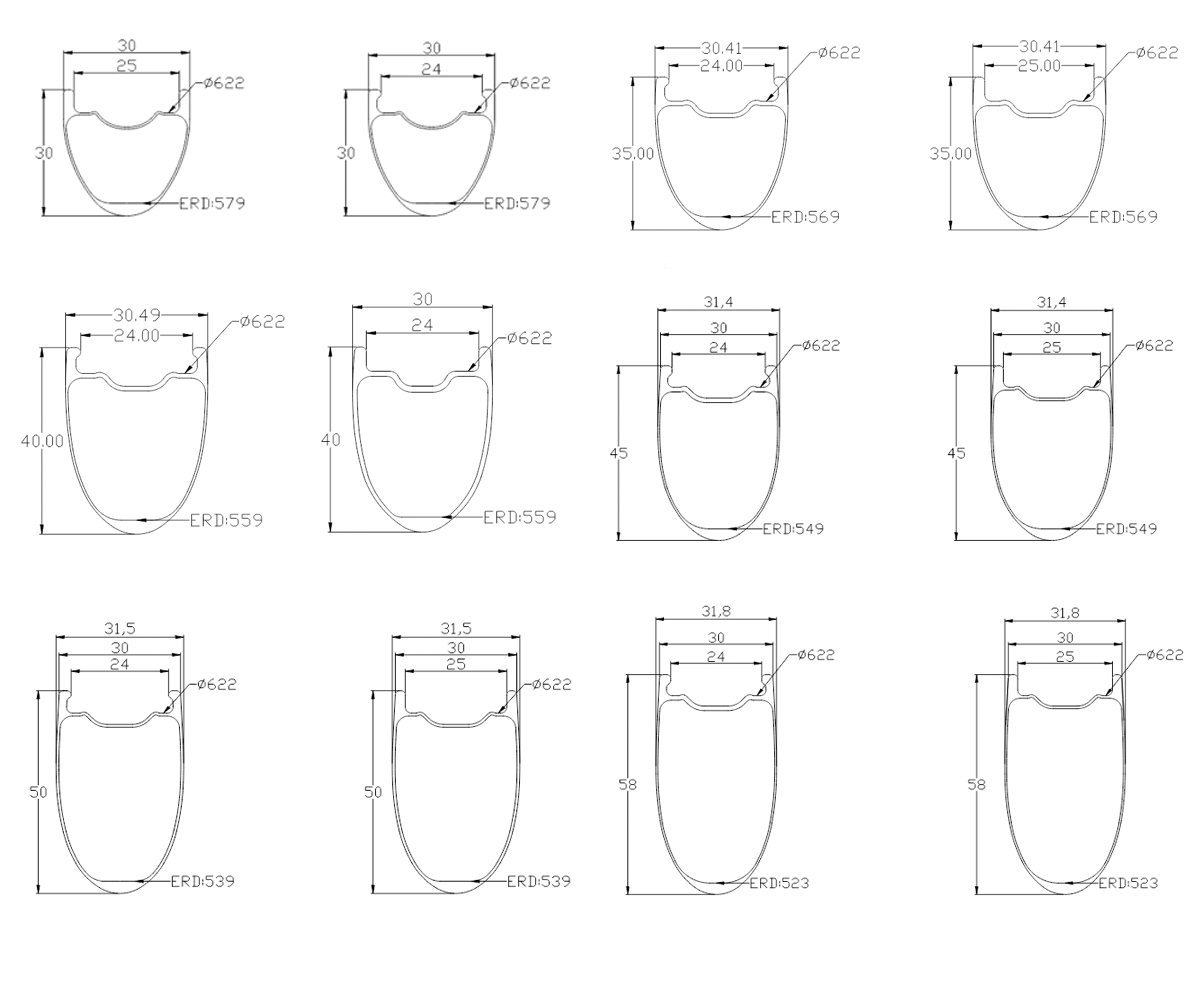

A 50mm rim was designed with lateral stiffness and airflow considerations in mind.

External Width and Tire Compatibility:

The 24mm internal width and 30mm external width rim size optimizes tire airbag geometry, enhances grip and stability, and accommodates a wide range of tire sizes.

Tubeless and Clincher Compatibility:

Excellent sealing, providing more options.

Spoke Hole Configurations:

Supports a variety of spoke hole counts, including 16/18/20/21/24/28/32/36, to accommodate different weave patterns and tension distribution requirements.

Rim Body and Rigidity:

Utilizing a double-layer carbon fiber reinforcement layer, with a focus on strengthening the tire bed and spoke hole areas, lateral stiffness is increased by approximately 40% compared to similar-sized aluminum rims, reducing pedaling deformation.

Brake Track Structure:

The 30mm-wide brake track features a flat, straight edge design. Combined with the heat-resistant properties of carbon fiber, it effectively dissipates heat, minimizing thermal decay during sustained braking. Exterior Finish: Standard UD matte paint is wear-resistant, scratch-resistant, and sun-resistant.

Application areas for the D50X30TL/HL-UL carbon bicycle rim:

OEM/ODM Partnership:

KOIBIKE's own factory, with ten years of experience in carbon wheel manufacturing, supports OEM/ODM manufacturing. We provide full-process support from design, prototyping, testing, and mass delivery, meeting brand customers' demands for quality, delivery time, and customization. We are more than just a trading company; we are a carbon fiber wheelset manufacturer with independent R&D capabilities and production facilities, dedicated to providing high-performance, highly reliable cycling solutions for customers worldwide.

An Adaptable Carrier for Multimodal Mobility Systems

Modern urban and suburban cycling is no longer limited to smooth asphalt roads; it frequently traverses complex surfaces such as paved roads, lightly graveled roads, rainwater manhole covers, and areas with dense expansion joints. A 24mm internal width rim effectively expands the tire's support camber, allowing 28–40C tires to form a more stable "contact dome" on less-than-ideal surfaces. This reduces tire wall wrinkling and deformation, thereby reducing the mechanical noise transmitted to the rider's torso from high-frequency micro-vibrations, improving neuromuscular tolerance during long, cross-regional commutes.

Components of Climate-Adaptable Cycling Equipment

In high humidity, extreme temperature fluctuations, or coastal salt spray environments, traditional narrow rims are susceptible to seal failure due to tire pressure fluctuations. The 24mm internal width design enhances the bead lock zone, maintaining the airtight seal stability of the vacuum system despite frequent thermal expansion and contraction, reducing the need for rehydration. It is suitable for rainy season endurance races, high-altitude cycling with large day-night temperature swings, and shared bike systems in coastal cities.

Gravel and Mixed Surface Exploration:

Suitable for wide tires and low tire pressures, it provides stable riding on unpaved surfaces such as gravel and dirt roads. High-end vehicle supporting and modification market: suitable for domestic and foreign high-end road vehicle brands, modification factories, and racing teams to carry out OEM production or customized development.

| Model | Weight (Gram) | Brake System | Inner Width | Outer Width | Depth | Available Appearance | Available Spoke Hole Counts |

D30X30TL/HL-NL | 400±15g | Disc Brake | 24mm | 30mm | 30mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D30X30TL/HL-SL | 380±15g | Disc Brake | 24mm | 30mm | 30mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D30X30TL/HL-UL | 330±15g | Disc Brake | 24mm | 30mm | 30mm | UD | 16/18/20/21/24/28/32/36H |

D35X30TL/HL-NL | 415±15g | Disc Brake | 24mm | 30mm | 35mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D35X30TL/HL-SL | 395±15g | Disc Brake | 24mm | 30mm | 35mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D35X30TL/HL-UL | 350±15g | Disc Brake | 24mm | 30mm | 35mm | UD | 16/18/20/21/24/28/32/36H |

D40X30TL/HL-NL | 430±15g | Disc Brake | 24mm | 30mm | 40mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D40X30TL/HL-SL | 410±15g | Disc Brake | 24mm | 30mm | 40mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D40X30TL/HL-UL | 365±15g | Disc Brake | 24mm | 30mm | 40mm | UD | 16/18/20/21/24/28/32/36H |

| D40X30TL/HL-650B-NL | 410±15g | Disc Brake | 24mm | 30mm | 40mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| D40X30TL/HL-650B-NL | 390±15g | Disc Brake | 24mm | 30mm | 40mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| D40X30TL/HL-650B-NL | 345±15g | Disc Brake | 24mm | 30mm | 40mm | UD | 16/18/20/21/24/28/32/36H |

D45X30TL/HL-NL | 450±15g | Disc Brake | 24mm | 30mm | 45mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D45X30TL/HL-SL | 430±15g | Disc Brake | 24mm | 30mm | 45mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D45X30TL/HL-UL | 385±15g | Disc Brake | 24mm | 30mm | 45mm | UD | 16/18/20/21/24/28/32/36H |

D50X30TL/HL-NL | 470±15g | Disc Brake | 24mm | 30mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D50X30TL/HL-SL | 450±15g | Disc Brake | 24mm | 30mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D50X30TL/HL-UL | 400±15g | Disc Brake | 24mm | 30mm | 50mm | UD | 16/18/20/21/24/28/32/36H |

100% Customizable

Customized Weaves & Finishes:

Customized Holes:

![]()

Weight Check:

Clean burrs & residues

Rim Diameters Check:

Cleaning & Packing

D50X30TL/HL-UL Product Show

We have been in carbon bicycle production industry since the year of 2015, so 10 years history and experiences.

100 workers, 30 management, 20 Engineers, 10 Sales.

Carbon bicycle rims, carbon spokes, carbon wheels, cranks and other carbon bicycle components.

Our factory area is 2500 square meters, with 2 production lines, one wheel building line.

10.000 pcs/month for carbon rims, 100.000 pcs/month for carbon spokes, 10.000 pcs/month for other carbon bicycle components like cranks, handlebars, thru axles etc.

10-15 days for carbon rims(100-200 pcs), 7-10 days for carbon spokes, 25-30 days for carbon wheels.

It depend on the product models, quantities and and other factors, takes carbon rim for example, price generate from 80-130 USD per piece.

2 years for carbo rims and wheels, 1 year for carbon spokes.

We focus on OEM/ODM service for customers mainly on Europe and American markets.

We have signed confidential agreement with our big OEM customers, so not allow to tell, but the big brands from Europe and America.

Our factory locates in Xiamen, China.