KOIBIKE Factory Trading Company independently develops and manufactures the FB25X80-26ER Disc Brake Snow Rim (Fat Rim) in its own factory. It maintains rigidity and resists brittleness even in sub-zero temperatures. As a veteran in wheel manufacturing, we possess a mature supply chain and advanced production processes, enabling us to efficiently meet the large-scale procurement and customization needs of B-end customers. These wheels are crafted from premium Toray carbon fiber, boasting a 25mm rim depth for structural stability and an 80mm outer width suitable for wide snow tires. The vacuum-integrated construction simplifies installation, and customizable finishes in various UD, marble, 12K, and 12K twill finishes enhance scratch and wear resistance. We provide one-stop service from production to after-sales service for our global partners.

Extra-Wide Compatibility and Enhanced Flotation:

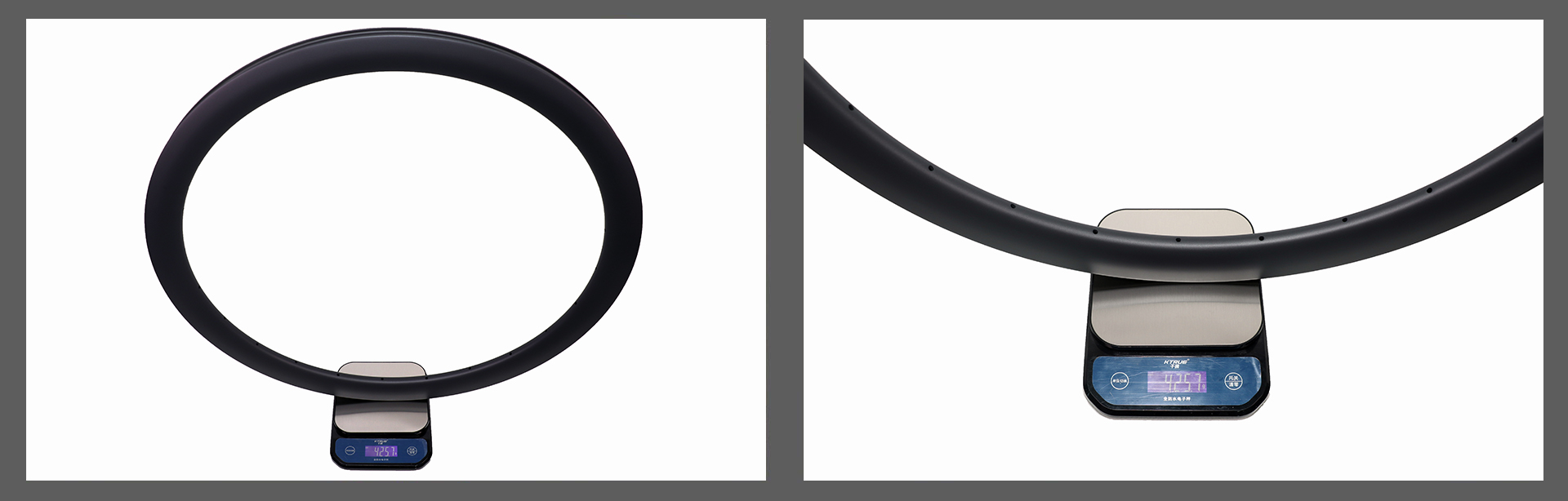

The 80mm outer width accommodates extra-wide snow tires, significantly increasing contact area with the snow and providing approximately 30% greater flotation compared to conventional rims. This effectively prevents vehicles and riders from sinking into the snow, making it easy to navigate soft, snowy terrain. Lightweight and High Rigidity: The ultra-light weight of 680 ± 15g, combined with the high strength of carbon fiber, ensures rim rigidity, reduces rotational inertia, and allows for instant acceleration. It can also withstand a rider weight of up to 120kg.

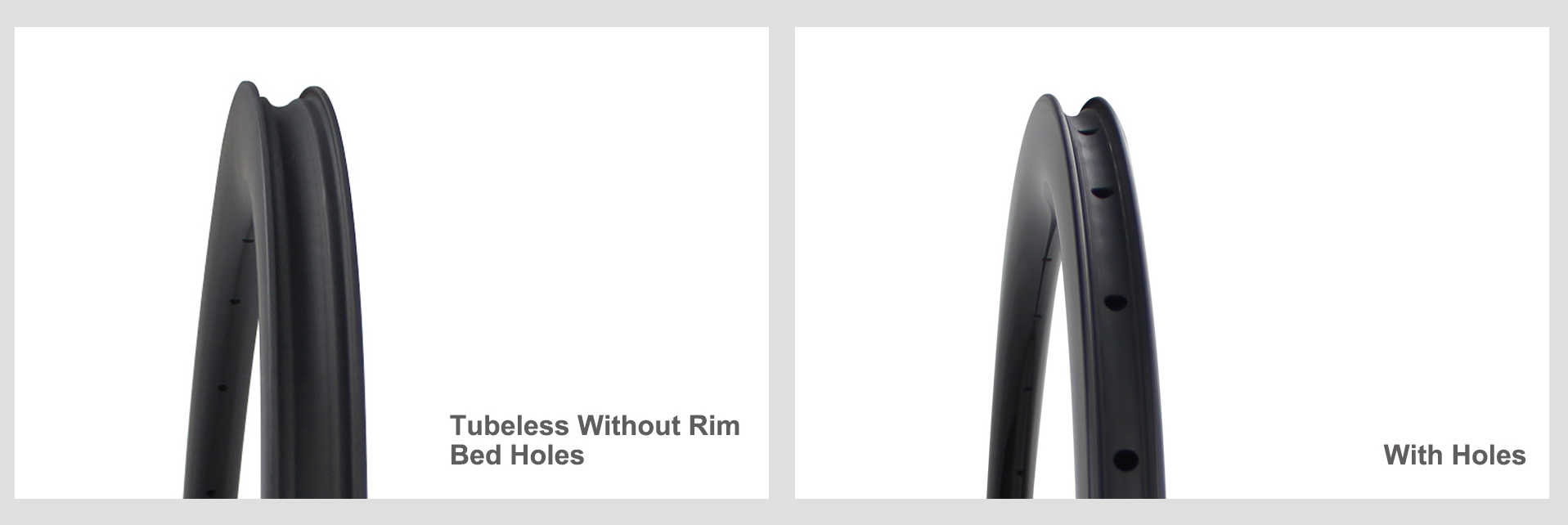

Vacuum-integrated Convenience:

The vacuum-integrated design, quick-release mechanism, and anti-freeze bearings simplify installation, reduce the need for inner tubes, and minimize the risk of flats. It also improves tire airtightness and ensures stable tire pressure in cold, snowy conditions.

Durable, Cold-Resistant Material:

The paint remains intact and the rim remains resistant to cracking in extremely cold, snowy conditions, providing excellent cold resistance and a long service life.

Strict Quality Control:

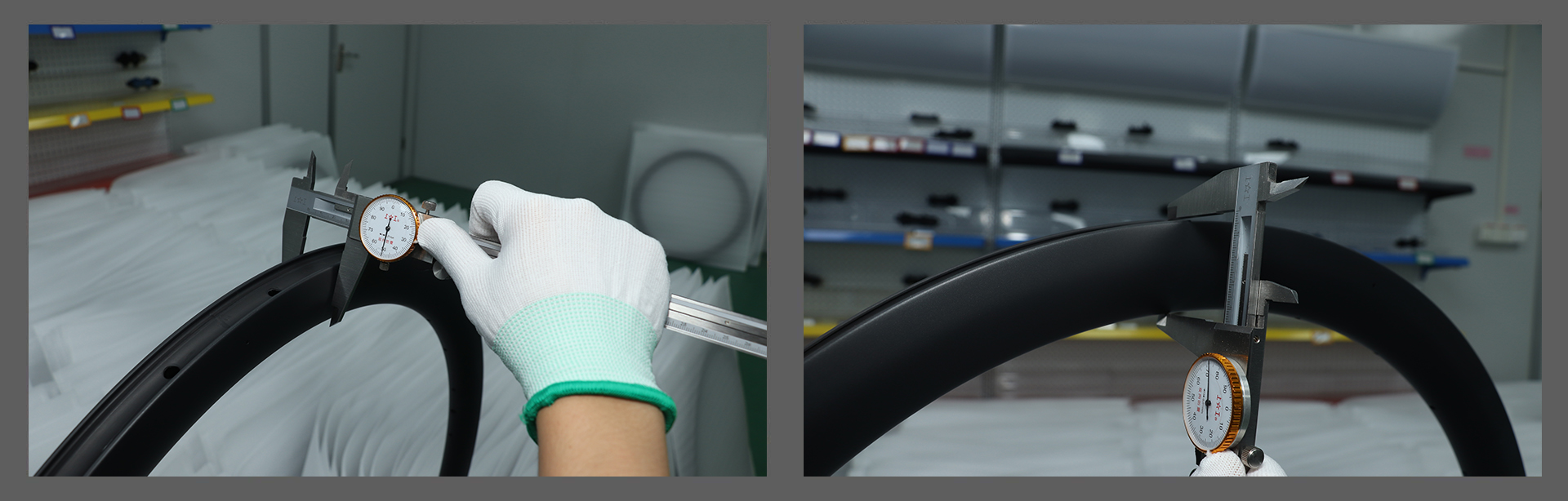

KOBIKE do 100% tire pressure(150 PSI), flatness(<0.2mm) and roundness(<0.2mm) inspections before shipping, also offering 2 years warranty for our carbon rims.

Rim Appearance and Paint:

The special paint finish showcases the unique carbon fiber texture for a premium feel. The paint finish undergoes a special wear-resistant treatment to effectively resist scratches from sand and rocks in snowy conditions, maintaining its appearance intact through long-term use, offering both aesthetics and durability.

Brake Track Construction:

The brake track features a widened and thickened design, perfectly matched to disc brake systems. This provides greater friction and contact area during braking, resulting in responsive braking and rapid heat dissipation. This ensures stable braking performance even under continuous braking, ensuring safe snow riding.

Rim Structure and Material:

The rim is constructed from multi-layer, precision-woven Toray carbon fiber, then heat-cured at high temperatures. Its 25mm height and 80mm outer width create a unique aerodynamic structure that reduces wind resistance at high speeds. Furthermore, the high strength of carbon fiber provides the rim with excellent deformation resistance, making it ideal for handling bumpy snowy conditions.

Application areas for the FB25X80-26ER carbon bicycle rim:

Snowbike Riding:

Designed specifically for snowbikes, the extra-wide rims accommodate wide tires, providing superior grip and flotation. Whether on flat slopes, rolling snow, or soft slopes, these wheels are perfect for daily riding and training for snowbike enthusiasts.

Winter Outdoor Sports:

In events like snowbike races and winter cross-country races, their lightweight, high rigidity, and excellent braking performance help competitors stand out from the competition and gain an advantage.

Snow Scenic Area Operation Vehicles:

Installing these wheels on snowbikes, snow patrol vehicles, and other vehicles within scenic areas improves maneuverability and stability on snowy terrain, ensuring visitor safety and operational efficiency while reducing vehicle maintenance costs.

Cycling Equipment Trade:

KOIBIKE factory-direct products offer superior performance and strong market competitiveness, making them suitable for traders seeking to expand into the domestic and international snowbike equipment market and meet the needs of diverse customer groups.

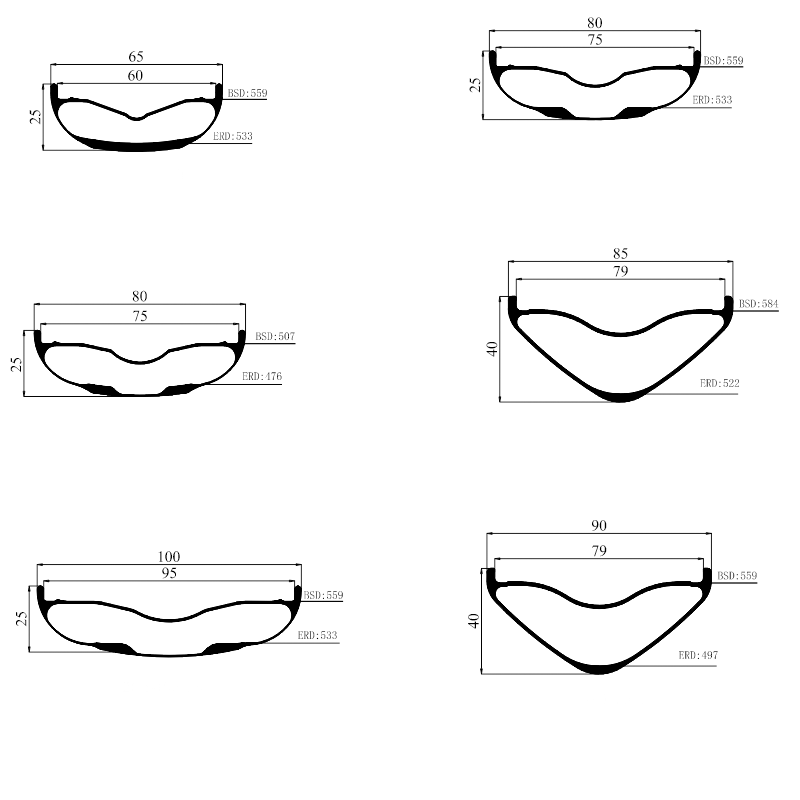

| Model | Weight (Gram) | Brake System | Inner Width | Outer Width | Depth | Available Appearance | Available Spoke Hole Counts |

| FB25X80-24ER | 580±15g | Disc Brake | 75mm | 80mm | 25mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| FB25X65-26ER | 600±15g | Disc Brake | 60mm | 65mm | 25mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| FB25X80-26ER | 680±15g | Disc Brake | 75mm | 80mm | 25mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| FB25X100-26ER | 750±15g | Disc Brake | 95mm | 100mm | 22mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

FB28X80-27.5ER | 615±15g | Disc Brake | 74mm | 80mm | 28mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

FB40X85-27.5ER | 660±15g | Disc Brake | 79mm | 85mm | 40mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

100% Customizable

Customized Weaves & Finishes:

Customized Laser Engraving Brake Track:

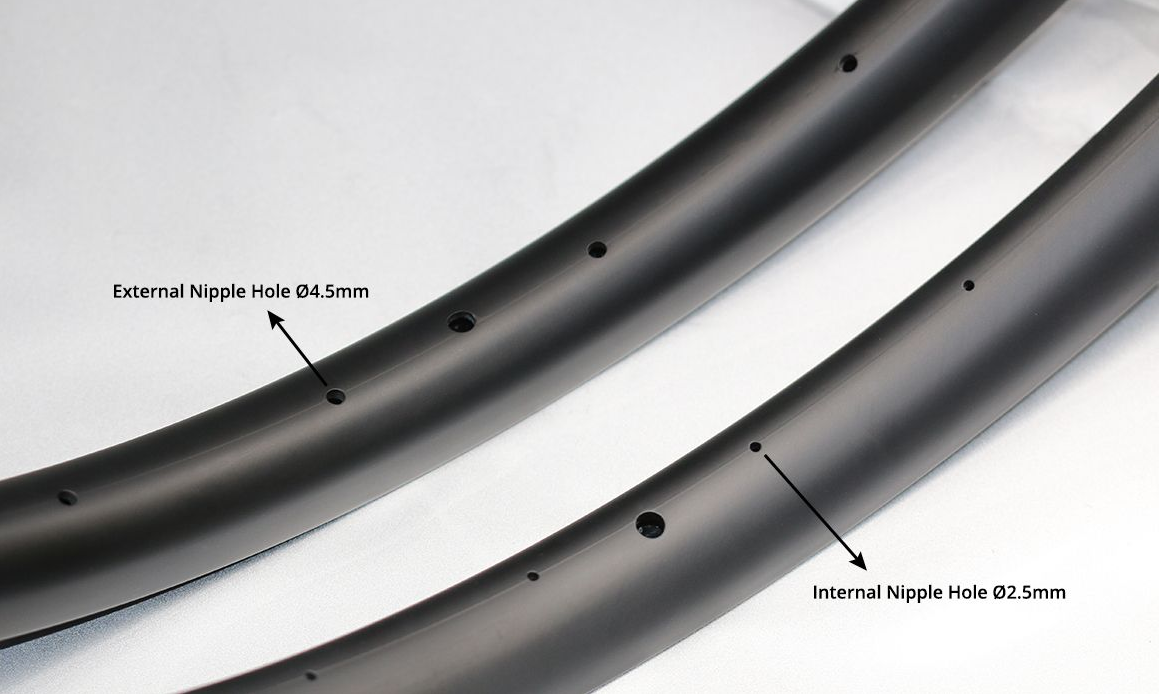

Customized Holes:

![]()

Weight Check:

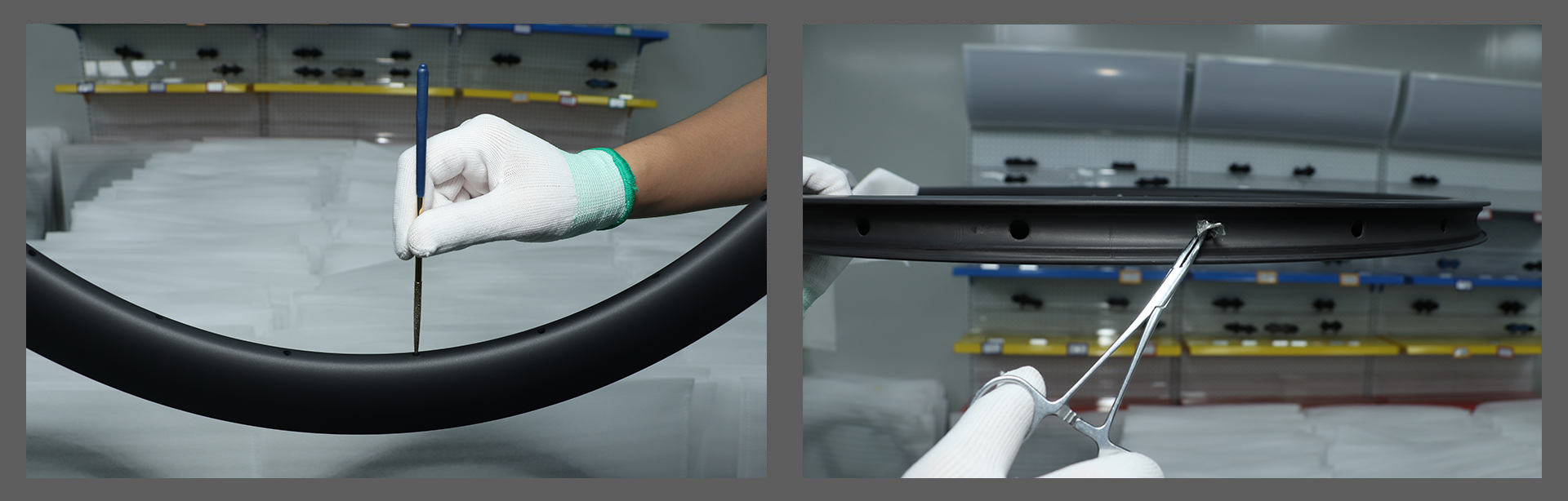

Clean burrs & residues

Rim Diameters Check:

Cleaning & Packing

We have been in carbon bicycle production industry since the year of 2015, so 10 years history and experiences.

100 workers, 30 management, 20 Engineers, 10 Sales.

Carbon bicycle rims, carbon spokes, carbon wheels, cranks and other carbon bicycle components.

Our factory area is 2500 square meters, with 2 production lines, one wheel building line.

10.000 pcs/month for carbon rims, 100.000 pcs/month for carbon spokes, 10.000 pcs/month for other carbon bicycle components like cranks, handlebars, thru axles etc.

10-15 days for carbon rims(100-200 pcs), 7-10 days for carbon spokes, 25-30 days for carbon wheels.

It depend on the product models, quantities and and other factors, takes carbon rim for example, price generate from 80-130 USD per piece.

2 years for carbo rims and wheels, 1 year for carbon spokes.

We focus on OEM/ODM service for customers mainly on Europe and American markets.

We have signed confidential agreement with our big OEM customers, so not allow to tell, but the big brands from Europe and America.

Our factory locates in Xiamen, China.