The KOIBIKE D50X28mm lightweight disc brake road wheel is manufactured by a manufacturer with independent R&D capabilities.

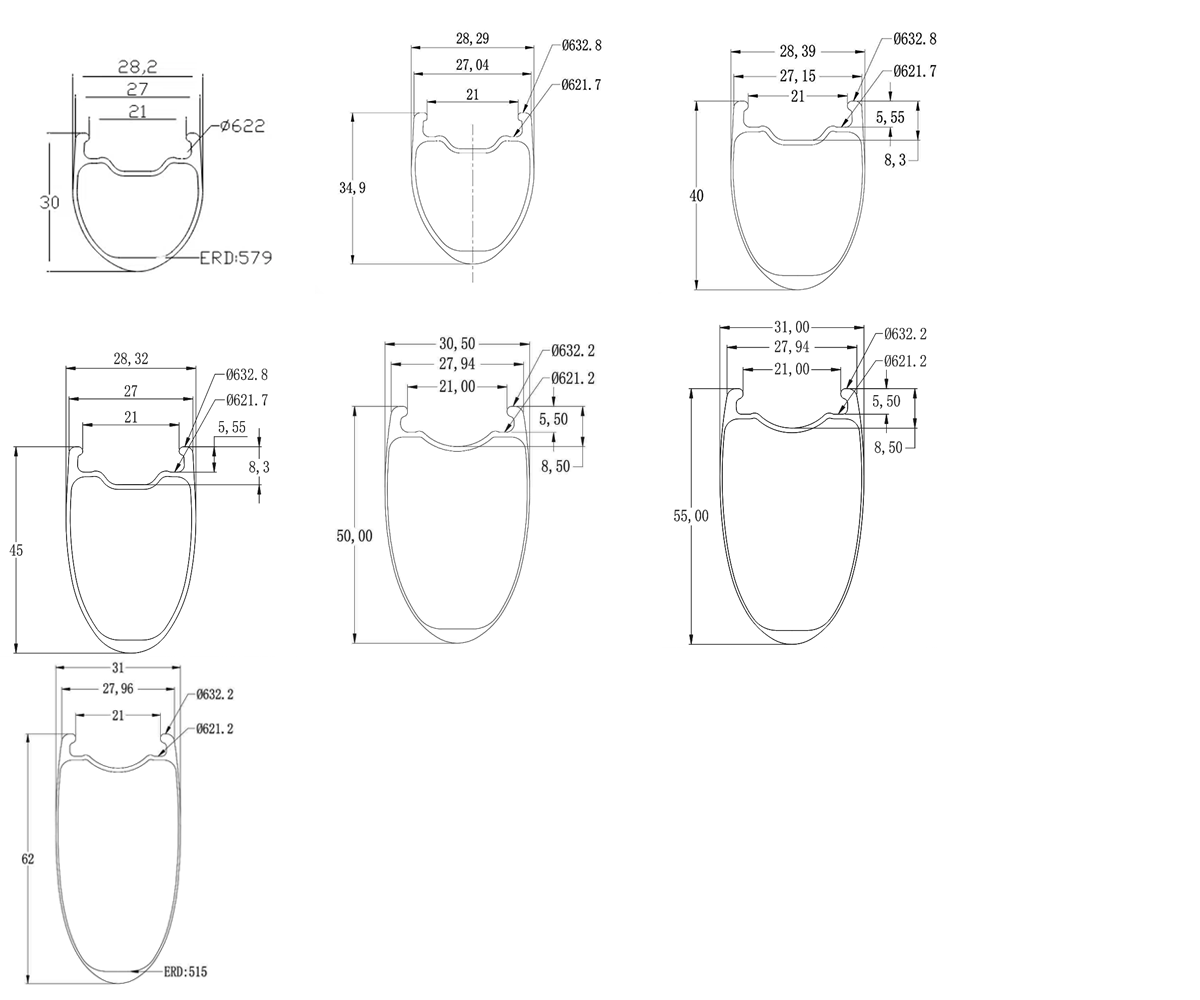

As a professional supplier, the factory ensures comprehensive quality control from design to production. Its core racing design delivers exceptional performance. The 50mm rim depth improves high-speed cruising performance by 10% compared to a 45mm rim depth. Its lightweight construction (385±15g per rim) effectively reduces rotational inertia for balanced performance. Regarding dimensions, the 21mm internal width provides stable support for tires ranging from 25-47cm, while the 30.5mm outer width creates a streamlined profile. When inflated, the tire forms a rounded, low-drag cross-section, delivering excellent grip and high-speed stability. The 27.94mm brake track width is specifically designed for disc brakes, allowing for ample heat dissipation to prevent thermal decay from continuous braking and ensure safe braking during cycling. In terms of appearance and craftsmanship, this wheel features a unique hot-stamped gold marble paint finish. A multi-layer UV curing process creates a three-dimensional texture. This not only exudes a high-end visual quality, but also offers excellent scratch and UV resistance, ensuring it maintains its aesthetics even after long-term use. As the source factory, we can meet the bulk purchasing needs of B-end customers and provide a stable supply chain.

KOIBIKE D50X28mm Aerodynamics and Wind Drag:

The 50mm rim depth has been aerodynamically optimized, and the streamlined profile with a maximum width of 30.5mm guides airflow smoothly. When inflated, the tire forms a smooth, rounded cross-section with low wind resistance.

This effectively reduces wind resistance and improves high-speed cruising efficiency by 10% compared to a 45mm rim depth, helping riders conserve energy and maintain high-speed cruising on flat roads.

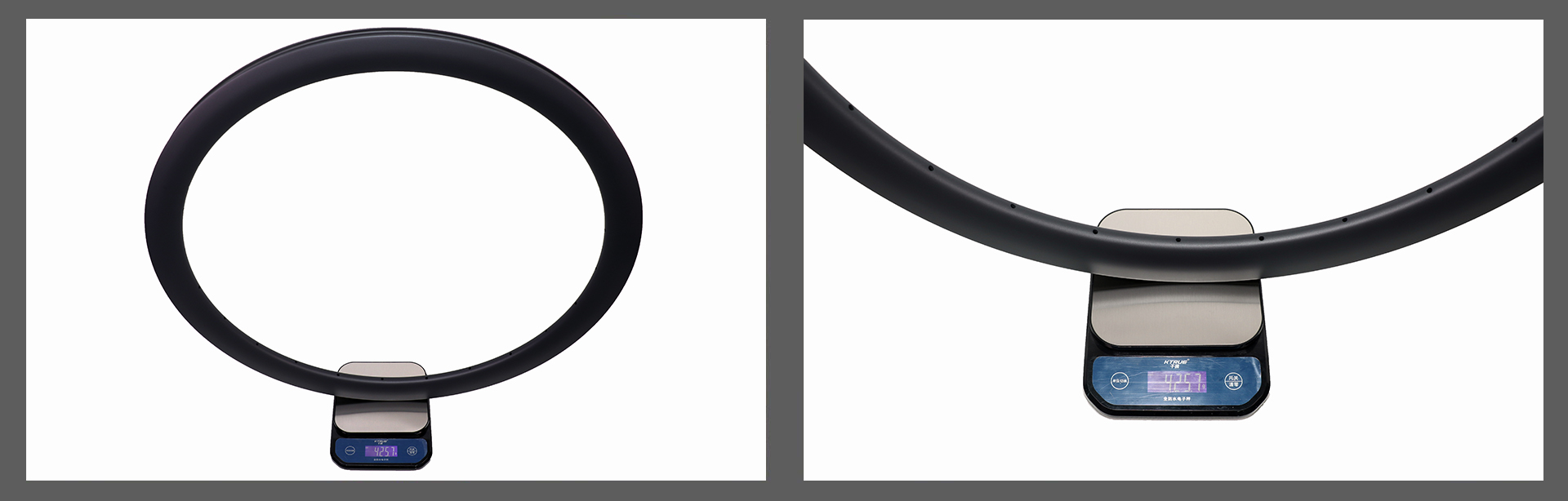

Ultralight Edition:

Featuring a single rim weight of just 385±15g, constructed using high-modulus carbon fiber and lightweight construction, this significantly reduces the wheel's rotational inertia, enabling more agile acceleration, easier climbing, and less fatigue after extended rides.

Stiffness:

The optimized carbon fiber layup process enhances the overall structural rigidity of the rim.

This improves power transmission efficiency, minimizes rim deformation during pedaling, and provides excellent stability during cornering, enabling it to withstand the various forces of intense riding.

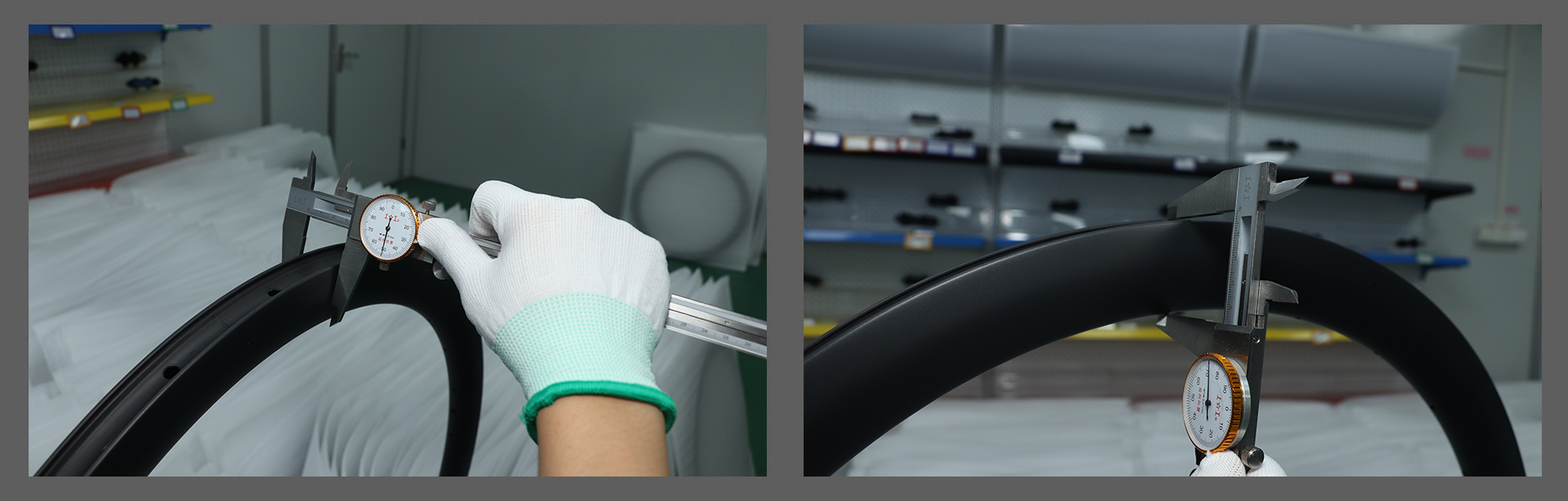

Rim Flatness and Roundness:

Precision CNC machining and rigorous testing ensure rim flatness and roundness within a tolerance of 0.3mm.

Advantages include smooth rim rotation, reduced rolling resistance, and protection against tire wear caused by unevenness. This ensures stability during braking and enhances the riding experience.

Strict Quality Control:

KOBIKE do 100% tire pressure(150 PSI), flatness(<0.2mm) and roundness(<0.2mm) inspections before shipping, also offering 2 years warranty for our carbon rims.

Special Gold Marble Paint Design:

Features a gold marble finish, combined with a multi-layer UV curing process, resulting in a three-dimensional, textured finish that is scratch-resistant and UV-resistant.

Advantages include a unique, high-end appearance, enhanced product recognition, long-lasting aesthetics, and adaptability to various environments.

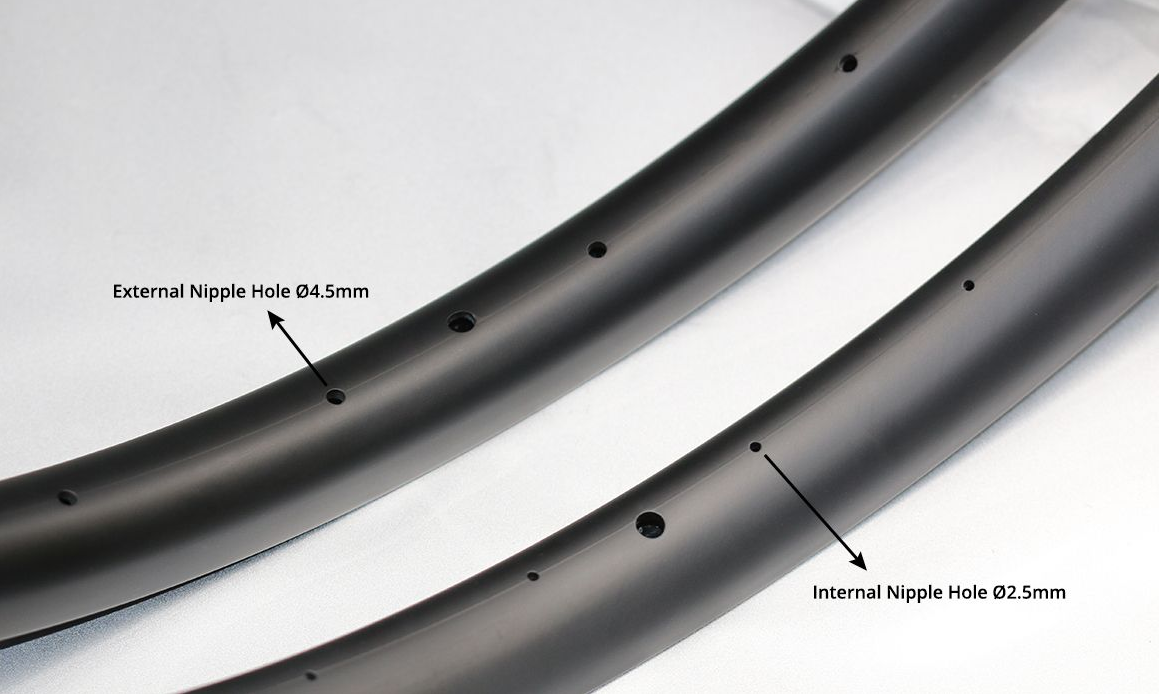

Drilling Angle:

Features precisely calculated drilling angles, with common options including 50, 70, and 90 degrees, and symmetrical or optimally offset to accommodate spoke installation angles.

Advantages include even spoke tension distribution, enhanced overall wheel strength, and extended rim life. It also facilitates spoke installation and adjustment.

Spoke lacing compatible hubs:

Features include support for a variety of common spoke lacing patterns (such as 2X and 3X), and compatibility with mainstream hub sizes (such as 100mm front hubs and 130/135mm rear hubs).

Advantages include strong compatibility, meeting the wheel assembly needs of various users and facilitating use with hubs of different brands and models, enhancing product versatility.

Application areas for the KOIBIKE D50X28mm carbon bicycle rim:

Road races, flat sprints, and long-distance time trials:

These wheels help riders conserve energy and maintain high-speed cruising in these extreme speed-demanding situations, enabling them to perform at their best.

Hill-riding events and high-intensity daily training:

The ultra-light weight per lap allows for more agile acceleration and less effort on hills, reducing fatigue after extended ride

Long-distance rides and road endurance races:

Rim flatness and roundness tolerances are controlled to within 0.3mm, ensuring smooth rotation, reducing rolling resistance, preventing abnormal tire wear, and ensuring braking stability.

Team displays and commercial events:

The unique gold marble finish allows for customizable and long-lasting aesthetics, making it particularly attractive in settings where individuality and quality are paramount.

Wheel assembly plants and bicycle repair shops:

Precisely calculated drilling angles, either symmetrical or optimally offset, match spoke installation angles, ensuring even spoke tension distribution and facilitating installation and adjustment. This improves efficiency and accommodates a variety of assembly needs.

For both DIY wheels and mass production by professional bicycle manufacturers:

This wheel supports a variety of common spoke lacing methods and is compatible with mainstream hub sizes, offering strong compatibility to meet diverse wheel assembly needs.

| Model | Weight (Gram) | Brake System | Inner Width | Outer Width | Depth | Available Appearance | Available Spoke Hole Counts |

R/D30X28TL-NL | 420/410±15g | Rim/Disc Brake | 21mm | 28mm | 30mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

R/D30X28TL-SL | 400/390±15g | Rim/Disc Brake | 21mm | 28mm | 30mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D30X28TL-UL | 305±15g | Disc Brake | 21mm | 28mm | 30mm | UD | 16/18/20/21/24/28/32/36H |

R/D35X28TL-NL | 440/430±15g | Rim/Disc Brake | 21mm | 28mm | 35mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

R/D35X28TL-SL | 420/410±15g | Rim/Disc Brake | 21mm | 28mm | 35mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D35X28TL-UL | 320±15g | Disc Brake | 21mm | 28mm | 35mm | UD | 16/18/20/21/24/28/32/36H |

R/D40X28TL-NL | 460/450±15g | Rim/Disc Brake | 21mm | 28mm | 40mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

R/D40X28TL-SL | 440/430±15g | Rim/Disc Brake | 21mm | 28mm | 40mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D40X28TL-UL | 340±15g | Disc Brake | 21mm | 28mm | 40mm | UD | 16/18/20/21/24/28/32/36H |

R/D45X28TL-NL | 485/470±15g | Rim/Disc Brake | 21mm | 28mm | 45mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

R/D45X28TL-SL | 465/450±15g | Rim/Disc Brake | 21mm | 28mm | 45mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D45X28TL-UL | 360±15g | Disc Brake | 21mm | 28mm | 45mm | UD | 16/18/20/21/24/28/32/36H |

R/D50X28TL-NL | 505/490±15g | Rim/Disc Brake | 21mm | 28mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

R/D50X28TL-SL | 485/470±15g | Rim/Disc Brake | 21mm | 28mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D50X28TL-UL | 385±15g | Disc Brake | 21mm | 28mm | 50mm | UD | 16/18/20/21/24/28/32/36H |

D55X28TL-NL | 520±15g | Disc Brake | 21mm | 28mm | 55mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D55X28TL-SL | 500±15g | Rim/Disc Brake | 21mm | 28mm | 55mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D55X28TL-UL | 420±15g | Rim/Disc Brake | 21mm | 28mm | 55mm | UD | 16/18/20/21/24/28/32/36H |

R/D62X28TL-NL | 550/540±15g | Rim/Disc Brake | 21mm | 28mm | 60mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

R/D62X28TL-SL | 530/520±15g | Rim/Disc Brake | 21mm | 28mm | 60mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D62X28TL-UL | 450±15g | Disc Brake | 21mm | 28mm | 60mm | UD | 16/18/20/21/24/28/32/36H |

100% Customizable

Customized Weaves & Finishes:

Customized Laser Engraving Brake Track:

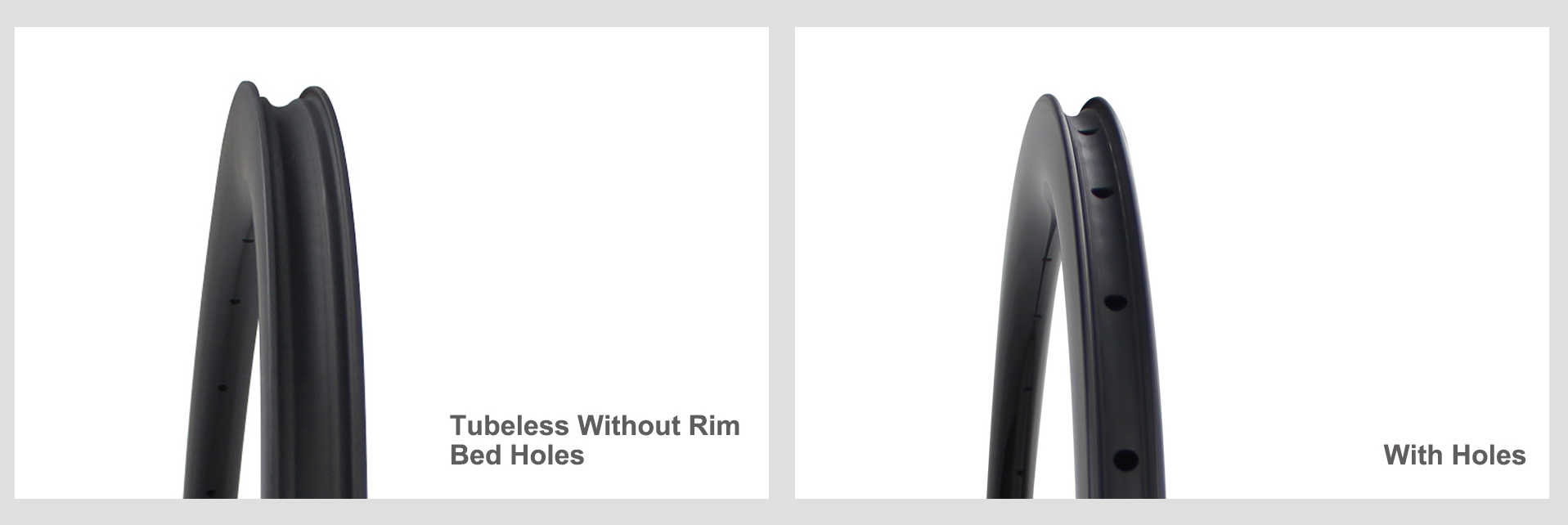

Customized Holes:

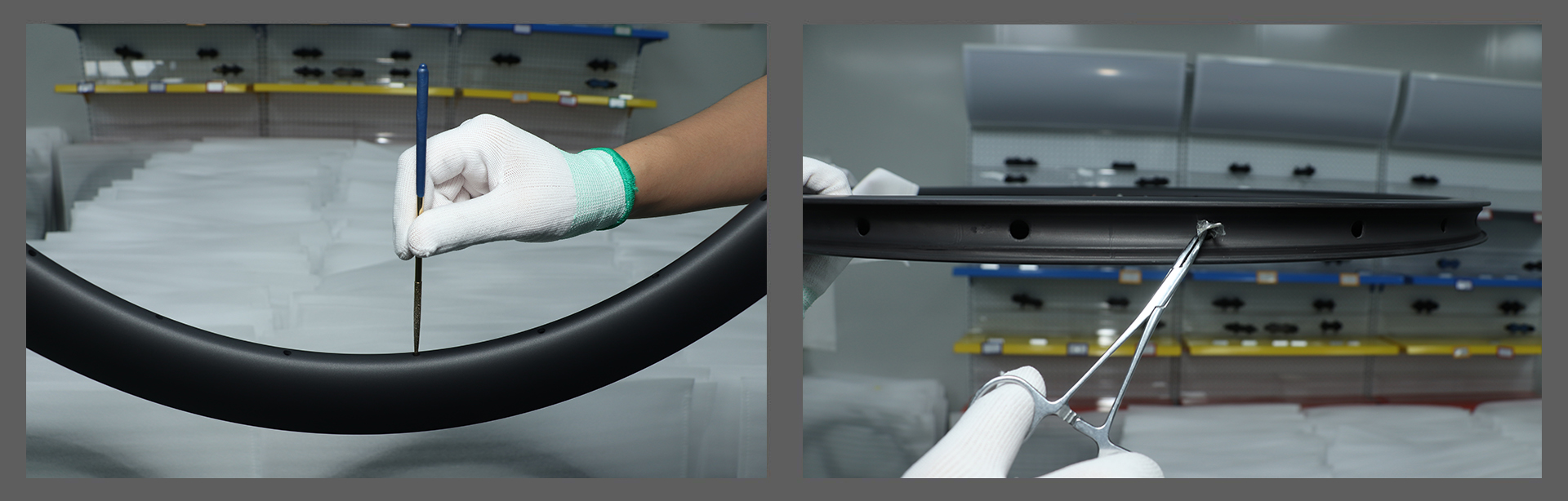

Weight Check:

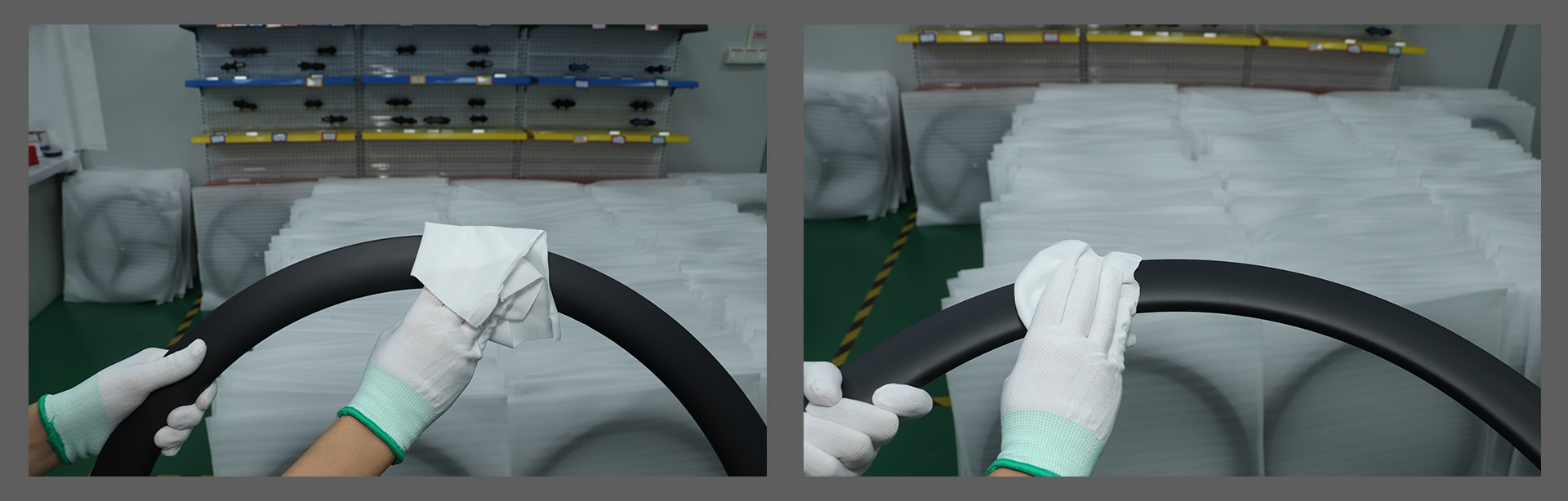

Clean burrs & residues

Rim Diameters Check:

Cleaning & Packing

D50X28TL-UL Product Show

We have been in carbon bicycle production industry since the year of 2015, so 10 years history and experiences.

100 workers, 30 management, 20 Engineers, 10 Sales.

Carbon bicycle rims, carbon spokes, carbon wheels, cranks and other carbon bicycle components.

Our factory area is 2500 square meters, with 2 production lines, one wheel building line.

10.000 pcs/month for carbon rims, 100.000 pcs/month for carbon spokes, 10.000 pcs/month for other carbon bicycle components like cranks, handlebars, thru axles etc.

10-15 days for carbon rims(100-200 pcs), 7-10 days for carbon spokes, 25-30 days for carbon wheels.

It depend on the product models, quantities and and other factors, takes carbon rim for example, price generate from 80-130 USD per piece.

2 years for carbo rims and wheels, 1 year for carbon spokes.

We focus on OEM/ODM service for customers mainly on Europe and American markets.

We have signed confidential agreement with our big OEM customers, so not allow to tell, but the big brands from Europe and America.

Our factory locates in Xiamen, China.