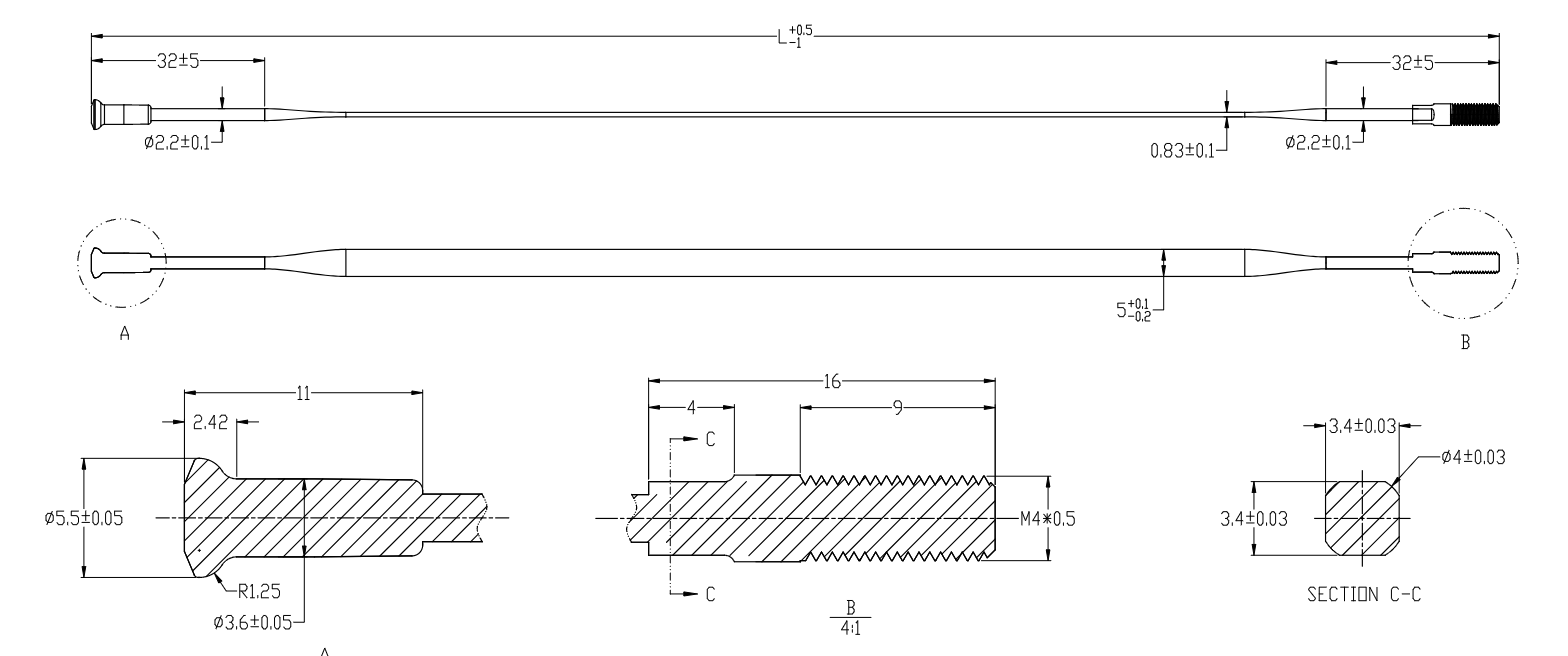

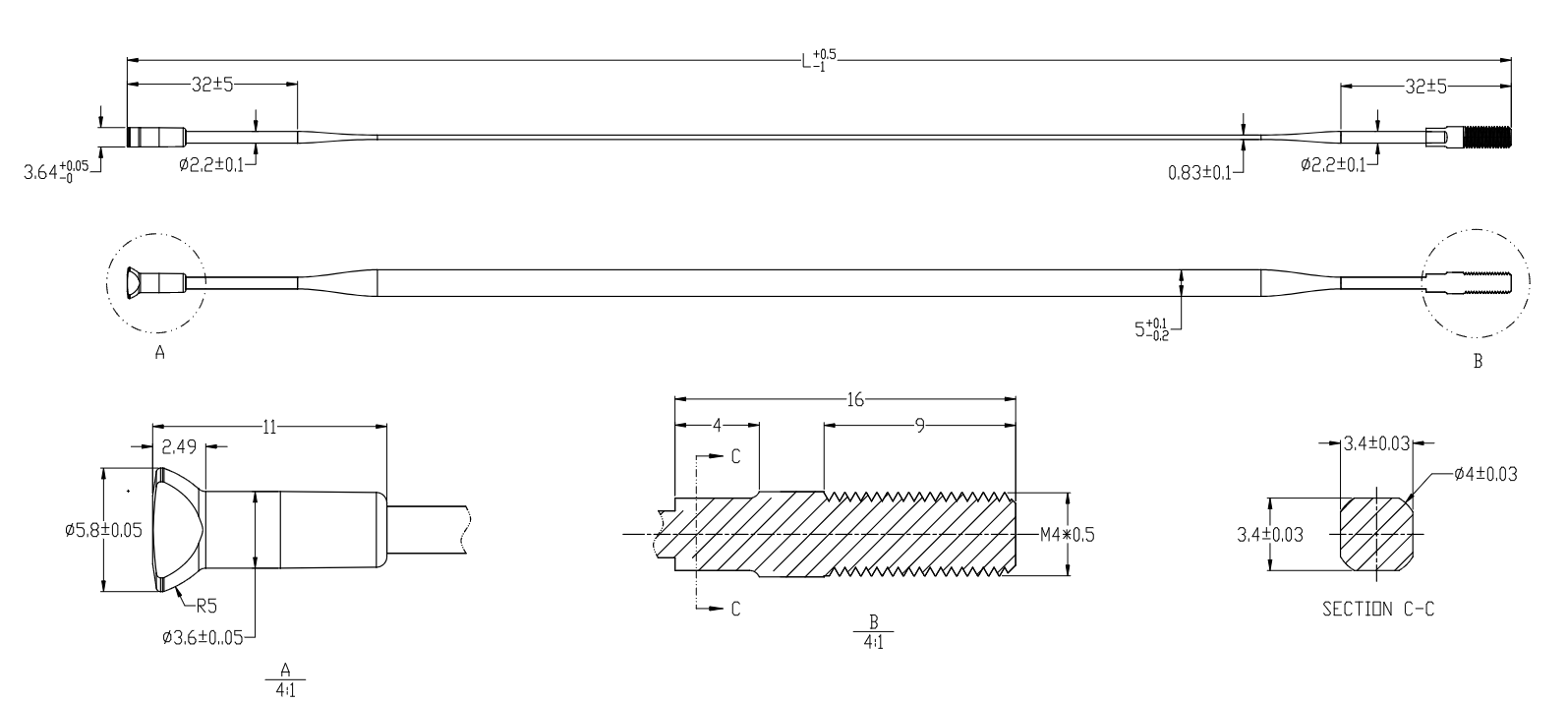

*KOIBIKE CS-A50/T50 carbon spokes are available with both T-shaped and A-shaped round-end designs to meet different hub interface requirements—the T-shaped head is compatible with specialized T-shaped hubs, while the round-end is compatible with traditional standard hubs.

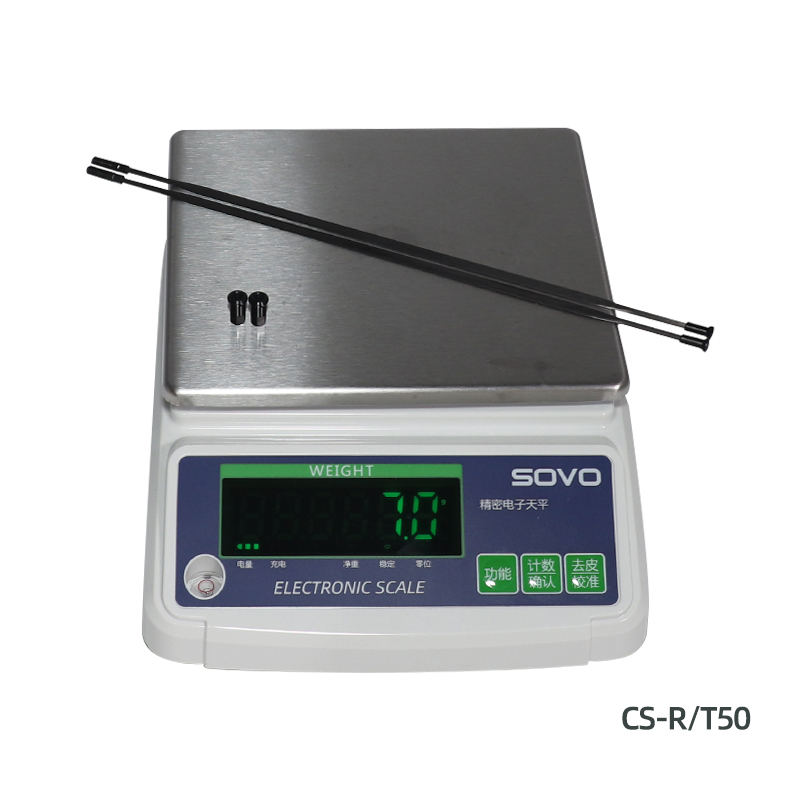

*Weighing a lightweight 3.5g per spoke, these spokes feature a flat carbon shank structure measuring 5.0±0.1mm wide and 0.83±0.1mm thick. They maintain the high stiffness of carbon spokes while improving aerodynamic performance and compatibility through optimized parameters.

*Steel shank lengths can be flexibly customized between 242-291mm to accommodate a variety of rim sizes, from road to mountain bike.

*The stainless steel threaded nuts on both ends are anodized black for both corrosion resistance and visual appeal. Combined with a glueless mechanical locking pultrusion process and a tensile strength of 3,000NF, these spokes are versatile and deliver both practicality and performance.

1. Lightweight and Improved Rotational Efficiency

Weighing 3.5g per spoke, the spokes are 12.5%-30% lighter than traditional steel spokes (4-5g per spoke). For a 28-spoke wheel, this translates to a weight reduction of 14-42g. This directly reduces the wheel's rotating mass and improves acceleration response. In a road climbing test (5% gradient), a wheel equipped with CS-A50/T50 wheels reduced rider force output by 8% on average, while improving climbing efficiency by 10%, compared to a steel-spoke wheel.

2. High Rigidity and Zero-Elongation Power Transmission

The zero-elongation properties of carbon fiber ensure that the spokes experience no noticeable stretch when stressed. The rider's pedaling force is directly transmitted to the rim, resulting in a 15% improvement in power transmission efficiency compared to steel spokes (elongation approximately 0.15%). This improves wheel response, especially during road sprints and mountain climbs, with less "force lag." The high rigidity of the carbon spokes (flexural modulus ≥ 180 GPa) ensures lateral wheel deflection of ≤ 0.3 mm during high-speed cornering, enhancing handling stability.

3. Durability and Low Maintenance Cost

Fatigue Resistance: Carbon fiber material has a fatigue resistance of up to 10^6 times (stress amplitude 100MPa), far exceeding steel spokes (approximately 5×10^5 times). This reduces the risk of spoke breakage by 40% during long-term, high-frequency cycling (such as daily 50km training)

One-Year Warranty and Stable Production Capacity: A one-year warranty covers quality issues such as spoke breakage and detached nuts. A stable annual production capacity of 20,000-30,000 units ensures timely spare parts supply, addressing the pain points of carbon spokes, such as difficult after-sales service and slow restocking. This makes it suitable for bulk purchases by wheel manufacturers or long-term use by individual users.

Application areas for the CS-A50/T50 carbon spoke wheel:

1. Road Cycling (Competition/Training)

Applications: Road criterion racing, long-distance endurance racing, and everyday training;

2. Mountain Biking (Light Off-Road/Leisure)

Applications: Cross-country cycling, trail riding, and casual mountain biking;

3. Wheel Upgrades and Maintenance

Applications: Upgrading traditional steel-spoke wheels and replacing damaged carbon spokes;

4. Wheel Manufacturer Supply

Applications: Mass production by road/mountain bike wheel manufacturers;

CS: Carbon Spoke

R: Round Head

T: T Head

Model | Intended Use | Diameter | Width | Thickness | Meterials | Weight PCS | Suggested Spoke Tension | Apperance | Available Spoke Length |

CS-R/T38 | Road/Gravel MTB | φ2.2 | 3.8mm | 1.13mm | Carbon fiber+Stainless Steel | 3.2~3.3g | 120~130kgf | Black Matte | 247~311mm |

CS-R/T50 | Road/Gravel MTB | φ2.2 | 5.0mm | 35mm | Carbon fiber+Stainless Steel | 3.2-3.3g | 120~130kgf | Black Matte | 242~291mm |

CS-T32 | Road/Gravel MTB | φ2.2 | 3.2mm | 0.75mm | Carbon fiber+Stainless Steel | 2.1~2.3g | 120~130kgf | Black Matte | 271~301mm |

The above parameters are for reference only, please consult our engineers for specific technical parameters.

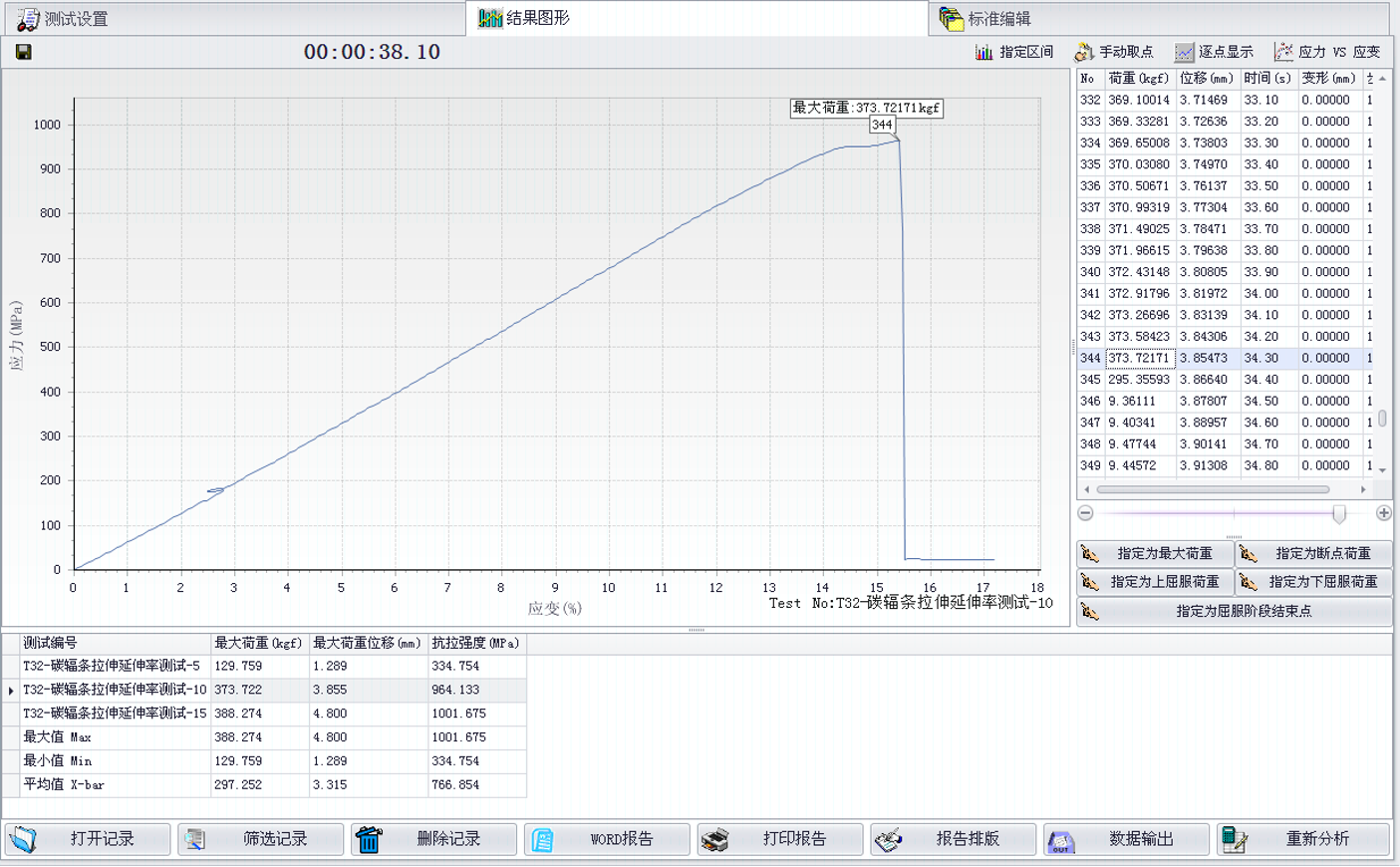

Comparsion Data

Comparison with Steel Spokes

| No. | Spoke Model | Weight(260mm) | Tensile Failure Test |

| 1. | Sapim CX-RAY | 4.36 grams/pcs | 3000N |

| 2. | DT Aerolite | 4.28 grams/pcs | 3000N |

| 3. | CS-R/T50 | 3.5 grams/pcs | 4000N |

Tesnsile Limit Test:

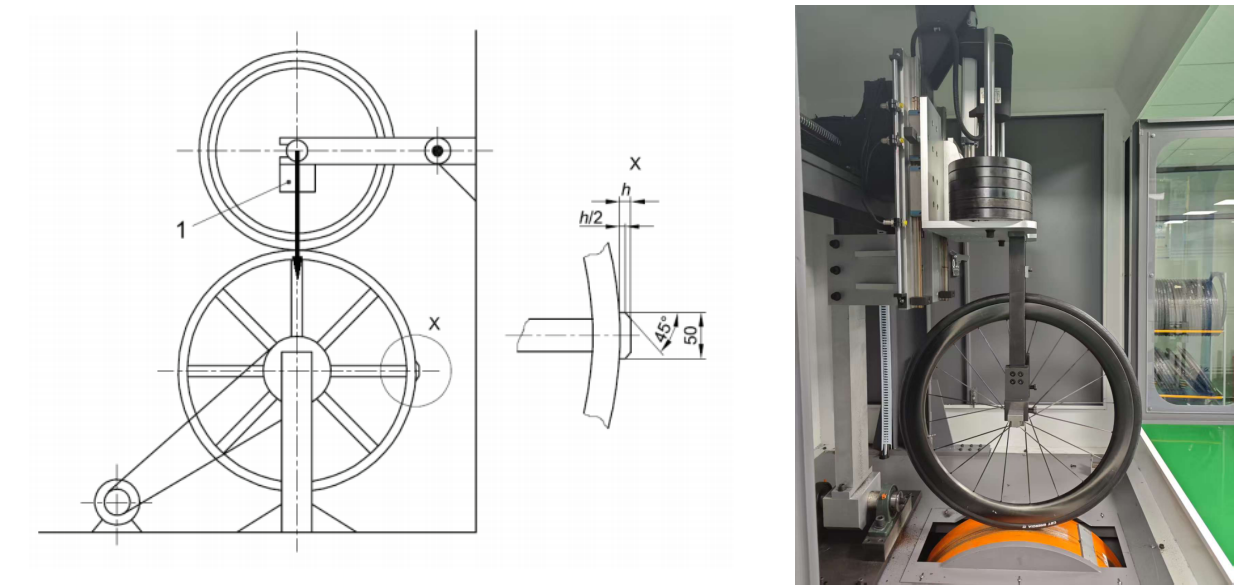

Road Running Test:

Wheel Building:

We have been in carbon bicycle production industry since the year of 2015, so 10 years history and experiences.

100 workers, 30 management, 20 Engineers, 10 Sales.

Carbon bicycle rims, carbon spokes, carbon wheels, cranks and other carbon bicycle components.

Our factory area is 2500 square meters, with 2 production lines, one wheel building line.

10.000 pcs/month for carbon rims, 100.000 pcs/month for carbon spokes, 10.000 pcs/month for other carbon bicycle components like cranks, handlebars, thru axles etc.

10-15 days for carbon rims(100-200 pcs), 7-10 days for carbon spokes, 25-30 days for carbon wheels.

It depend on the product models, quantities and and other factors, takes carbon rim for example, price generate from 80-130 USD per piece.

2 years for carbo rims and wheels, 1 year for carbon spokes.

We focus on OEM/ODM service for customers mainly on Europe and American markets.

We have signed confidential agreement with our big OEM customers, so not allow to tell, but the big brands from Europe and America.

Our factory locates in Xiamen, China.