KOIBIKE leverages its in-house expertise in carbon fiber off-road rims to create the XC-W25X35HL-29ER-UL off-road wave rims. The core breakthrough lies in the synergy between the 25mm low-profile wave structure and the straight-edge, hookless design for off-road use. The entire process, from wave-shaped carbon fiber cutting and off-road-grade coating to straight-edge precision machining, is fully controllable. The rims are constructed from Toray T800-grade carbon fiber, using a short-curvature cold-pressing process to create a 25mm low-profile wave rim. The wave crests are shortened to 35mm to enhance torsional resistance, while the trough depth is 20mm, providing a bump buffer. The straight-edge hookless grooves eliminate hooks, further reducing weight while creating a surface-to-surface seal with 2.2-2.7-inch tires. Low tire pressures of 18-30 mm are suitable for wide off-road tires, and the weight of 320 ± 15 grams is a significant advantage for a 25mm low-profile rim. The rims also feature a scratch-resistant ceramic coating in a variety of finishes.

Low-profile wave rim innovation for torsional resistance:

The 25mm low-profile rim features a "short-pitch wave structure" with a 35mm wave crest spacing, 20% shorter than traditional wave rims, creating denser support points for torsional resistance. When a 120kg rider negotiates corners or crushes gravel, the rim experiences lateral deflection of ≤0.15mm, 18% less than a straight-sided rim of the same height. This addresses the "easy deformation" issue of low-profile off-road rims, while also maintaining short-distance undulation without compromising steering flexibility, ensuring greater agility on narrow mountain trails.

Straight-sided hookless rim compatibility for wide tires:

The straight-sided hookless rim groove eliminates the weight of the hook, saving approximately 8% (25 grams) compared to hooked-sided rims. It also provides full contact with 2.2-2.7-inch off-road tires, increasing the sealing area by 22% compared to hooked-sided rims. At low tire pressures of 18-30 mm, the tire bead maintains a close fit with the undulated rim, reducing air leakage by 30% compared to hooked-sided rims, reducing emergency response time after a puncture while off-roading.

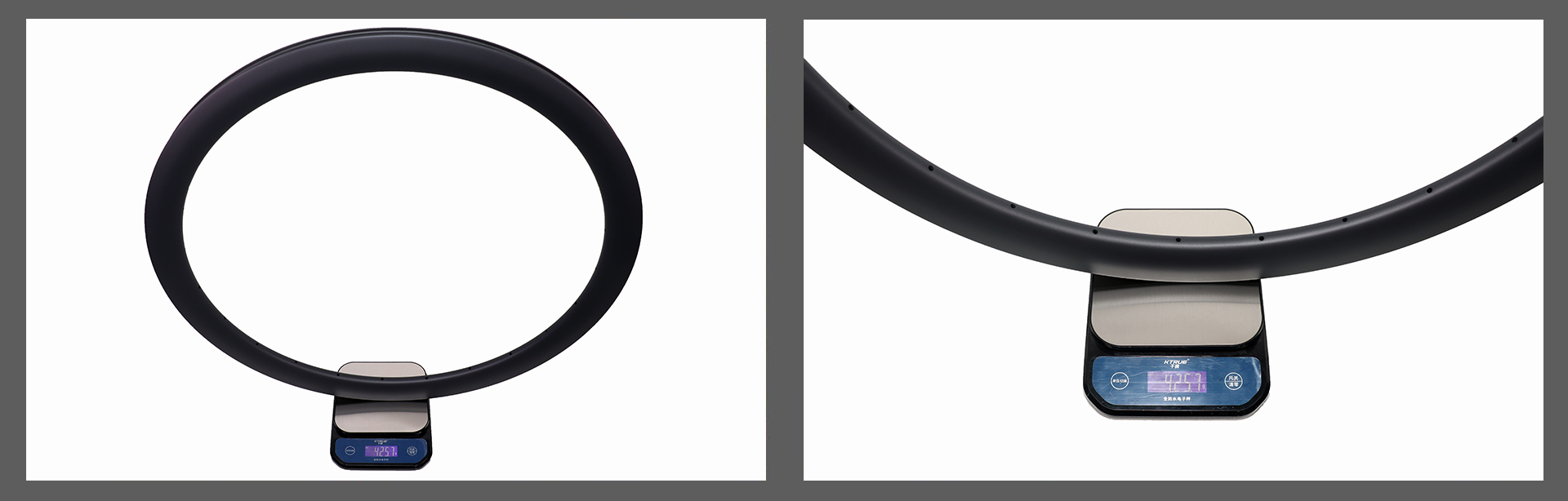

Lightweight and Balanced:

The 320±15g weight is achieved through "precise wave material distribution"—three layers of carbon fiber reinforce the wave crests for support, two layers provide cushioning in the troughs, and the straight, hookless rims eliminate the need for metal hooks. Overall, the rims are 12% lighter than comparable off-road rims. The T800 carbon fiber boasts a shear strength of 5.0GPa, keeping radial stress within a safe range even with a 120kg rider load, ensuring a balanced balance of lightweight and durability.

Off-road Functional Finish:

The full matte finish utilizes a "coarse-grain anti-scratch coating" with a surface hardness of HRC52, leaving stone scratches ≤0.01mm deep. The smoked black process is achieved through dyeing the carbon tubes, resulting in a coating thickness of only 0.02mm without adding weight. The unpainted version reveals the original carbon fiber grain, improving heat dissipation by 15% compared to painted rims, making it ideal for heat dissipation during extended off-road riding.

Optimized Low-Pressure Cushioning:

Across the low tire pressure range of 18-30 psi, the wave rim's "Dynamic Deformation Cushioning" delivers a subtle 1.2mm deformation at the troughs, absorbing the impact of muddy roads and potholes while reducing vibration. At 30 psi, the carbon fiber layer at the crests tightly supports the tire bead, ensuring rolling efficiency on hard-shoulder roads and adapting to the pressure-shifting requirements of off-road riding.

Strict Quality Control:

KOBIKE do 100% tire pressure(150 PSI), flatness(<0.2mm) and roundness(<0.2mm) inspections before shipping, also offering 2 years warranty for our carbon rims.

Wave rim details:

The 25mm-tall rim features a 25mm crest height and a 20mm trough depth, with a uniform spacing of 35mm. Based on off-road mechanics simulations, this specification provides the optimal balance between torsional resistance and cushioning. The carbon fiber layers utilize a "cross-weave + short-distance stacking" technique. The fibers at the crests are oriented at 45° to the rim tangent, enhancing lateral torsional resistance. The fibers at the troughs are distributed radially, improving cushioning toughness.

Straight-edge hookless construction:

The straight-edge edges feature a 0.3mm radius to prevent bead scratches during tire installation. A double spiral sealing groove is incorporated into the inner side. When used with a tubeless tire, the "wave-shaped rim body fits" and the sealing grooves lock in the adhesive. At 30psi, the 24-hour air leakage rate is ≤0.6psi, a 25% improvement in sealing compared to single-groove straight-edge rims.

Painting process adaptation:

The wavy surface features a zoned anti-scratch treatment—the coating thickness is 0.04mm at the crests (for enhanced wear resistance) and 0.02mm at the valleys (to reduce sediment accumulation). The UD textured version, with a fine polish that preserves the original carbon fiber grain, is 5 grams lighter than the painted rim. The original grain structure also improves heat dissipation, reducing rim temperature by 8°C during continuous downhill braking.

Weight-Restricted Reinforced Area:

Targeting riders under the 120kg weight limit, the carbon fiber stacking density has been increased by 30%. Finite element analysis shows that stress values in this area are 25% lower than in the normal area when loaded. The wave structure also disperses stress toward the wave crest, preventing overload damage at the flange.

Application areas for the XC-W25X35HL-29ER-ULcarbon bicycle rim:

XC Cross-Country Racing:

The flexible torsional resistance of the low-profile wave structure combined with the lightweight design of the straight-edge hookless design are ideal for the undulating terrain of XC racing. The short-distance wave structure provides torsional resistance, ensuring cornering speed, while the 320g weight improves climbing efficiency. The 2.2-2.7-inch wide tires are suitable for gravel and muddy sections of the track, making it an ideal choice for professional athletes to improve their performance. The innovative stress-distributing wave structure reduces rim failure during racing. All-Mountain

Light Trail:

Compatible with wide tires and low tire pressures of 18-30 mm, it can handle the gentle roughness of all-mountain terrain. The straight-sided, hookless design provides high airtightness, reducing the risk of punctures. The white rim with smoked black paint is highly visible in the mountains and forests, making it suitable for advanced riders exploring moderately difficult trails, balancing performance and safety.

Daily Trail Training:

A balance of lightweight and durability, suitable for daily trail training. The short-pitch wave structure provides strong torsional resistance, capable of withstanding frequent cornering and bumpy training. The straight-sided, hookless design simplifies tire changes, allowing you to switch between a 2.2C hard tire or a 2.7C soft tire depending on the terrain, improving training efficiency.

Personalized Trail Modification:

Combining UD/marble finishes with a variety of paint options, the wave rim is a distinctive off-road style, perfect for off-road enthusiasts who seek personalized modifications. The unpainted, natural version reveals a carbon fiber texture, paired with fluorescent spokes, creating a unique off-road setup and enhancing rider recognition.

High-end off-road vehicles:

As a core component for premium XC off-road vehicles, the 25mm low-profile wave and straight-edge hookless design enhance the vehicle's off-road agility and lightweight performance. A variety of paint options are available to match the vehicle's color scheme, helping vehicle manufacturers create differentiated products and attract consumers who value both racing performance and everyday off-roading.

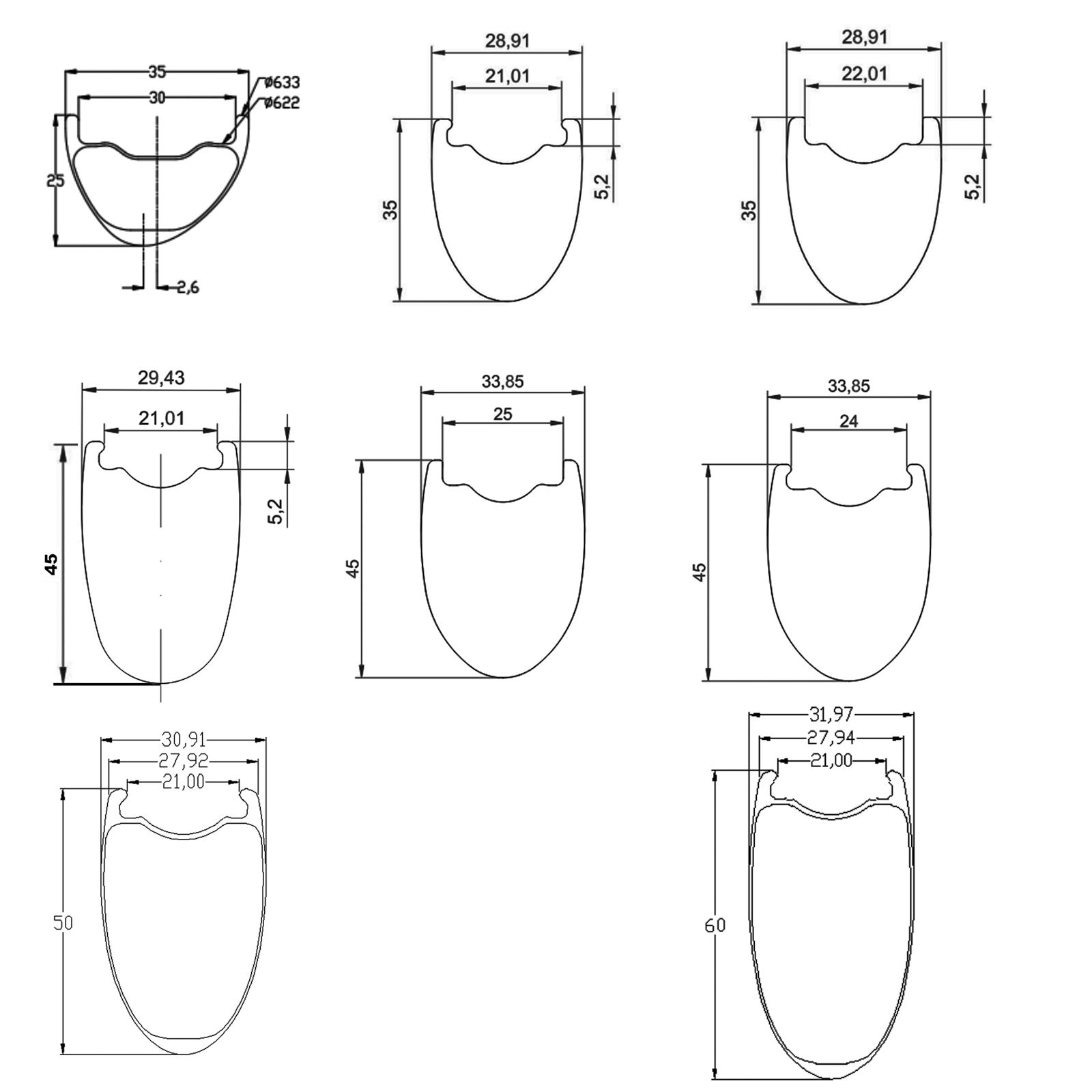

| Model | Weight(Gram) | Inner Width | Outer Width | Depth | Brake System | Available Appearance | Available Spoke Hole Counts |

| W35X28TL-SL | 360±15 | 21mm | 28mm | 35mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| W35X28TL-UL | 340±15 | 21mm | 28mm | 35mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| W35X28HL-SL | 360±15 | 22mm | 28mm | 35mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| W35X28HL-UL | 340±15 | 22mm | 28mm | 35mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| W45X28TL-UL | 380±15 | 21mm | 28mm | 45mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| W45X28HL-UL | 380±15 | 22mm | 28mm | 45mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| W50X28TL-NL | 490±15 | 21mm | 28mm | 50mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| W50X28TL-SL | 470±15 | 21mm | 28mm | 50mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| W50X28TL-SL | 430±15 | 21mm | 28mm | 50mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| W50X28TL-UL | 400±15 | 21mm | 28mm | 50mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| W60X28TL-NL | 530±15 | 21mm | 28mm | 60mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| W60X28TL-SL | 510±15 | 21mm | 28mm | 60mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| W60X28TL-UL | 490±15 | 21mm | 28mm | 60mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| W45X32TL-UL | 380±15 | 24mm | 32mm | 45mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| W45X32HL-UL | 380±15 | 25mm | 32mm | 45mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| XC-W25X35HL-29ER-SL | 360±15 | 30mm | 35mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-W25X35HL-29ER-UL | 320±15 | 30mm | 35mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

The above parameters are for reference only, please consult our engineers for specific technical parameters.

100% Customizable

Customized Weaves & Finishes:

Customized Holes:

![]()

Weight Check:

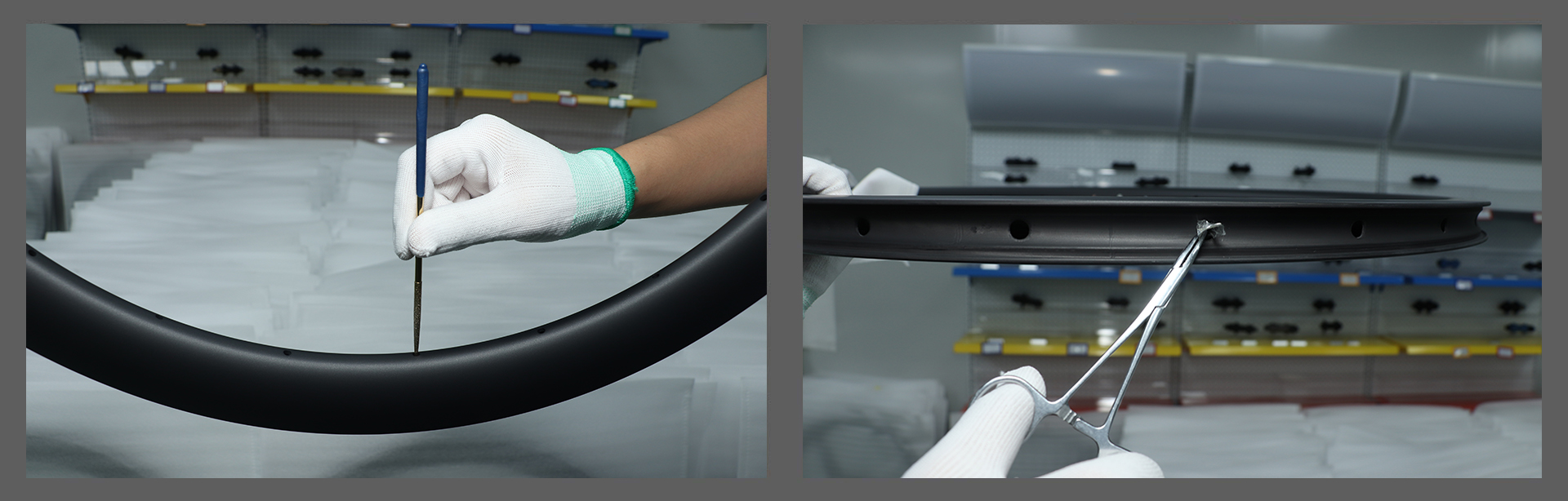

Clean burrs & residues:

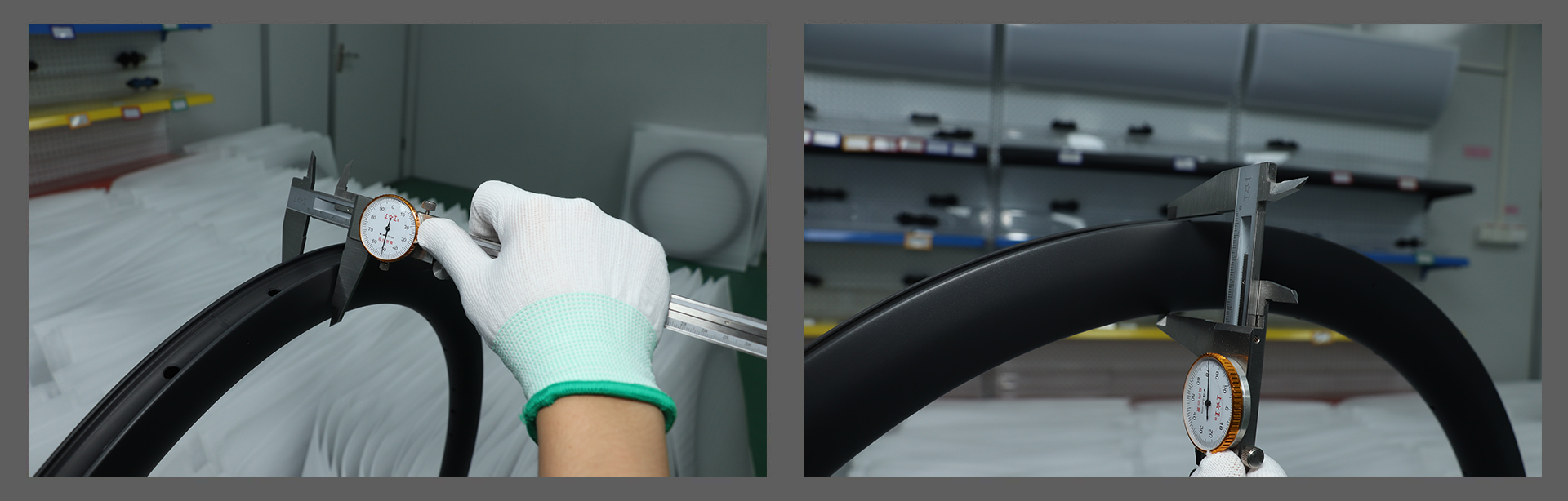

Rim Diameters Check:

Cleaning:

Packing:

We have been in carbon bicycle production industry since the year of 2015, so 10 years history and experiences.

100 workers, 30 management, 20 Engineers, 10 Sales.

Carbon bicycle rims, carbon spokes, carbon wheels, cranks and other carbon bicycle components.

Our factory area is 2500 square meters, with 2 production lines, one wheel building line.

10.000 pcs/month for carbon rims, 100.000 pcs/month for carbon spokes, 10.000 pcs/month for other carbon bicycle components like cranks, handlebars, thru axles etc.

10-15 days for carbon rims(100-200 pcs), 7-10 days for carbon spokes, 25-30 days for carbon wheels.

It depend on the product models, quantities and and other factors, takes carbon rim for example, price generate from 80-130 USD per piece.

2 years for carbo rims and wheels, 1 year for carbon spokes.

We focus on OEM/ODM service for customers mainly on Europe and American markets.

We have signed confidential agreement with our big OEM customers, so not allow to tell, but the big brands from Europe and America.

Our factory locates in Xiamen, China.