This 40mm-deep, 26mm-wide carbon road wheel is designed for tubular tires and is ideal for all types of racing, endurance riding, and everyday training. Crafted from Japanese Toray carbon fiber and incorporating proprietary layup technology, it achieves an ideal balance of strength and lightness, with a single rim weighing as little as 320g. Its construction is also optimized for tubular tires. Produced in a state-of-the-art facility, we produce over 10,000 wheels per month and offer customization options for paint finishes, hole counts, and spokes, catering to wholesale and private label needs. Annual sales exceed 100,000 wheels.

As a professional carbon road wheel manufacturer, we pride ourselves on being a reliable supplier to customers worldwide. We offer wholesale services and bulk ordering options to meet large-scale demands. We support private label customization and offer comprehensive OEM and ODM solutions to meet diverse market needs. Whether working with dealers, traders, or distributors, we guarantee consistent quality and flexible terms. This meticulously crafted carbon road wheel embodies our commitment to manufacturing excellence and is the ideal choice for those seeking premium cycling components.

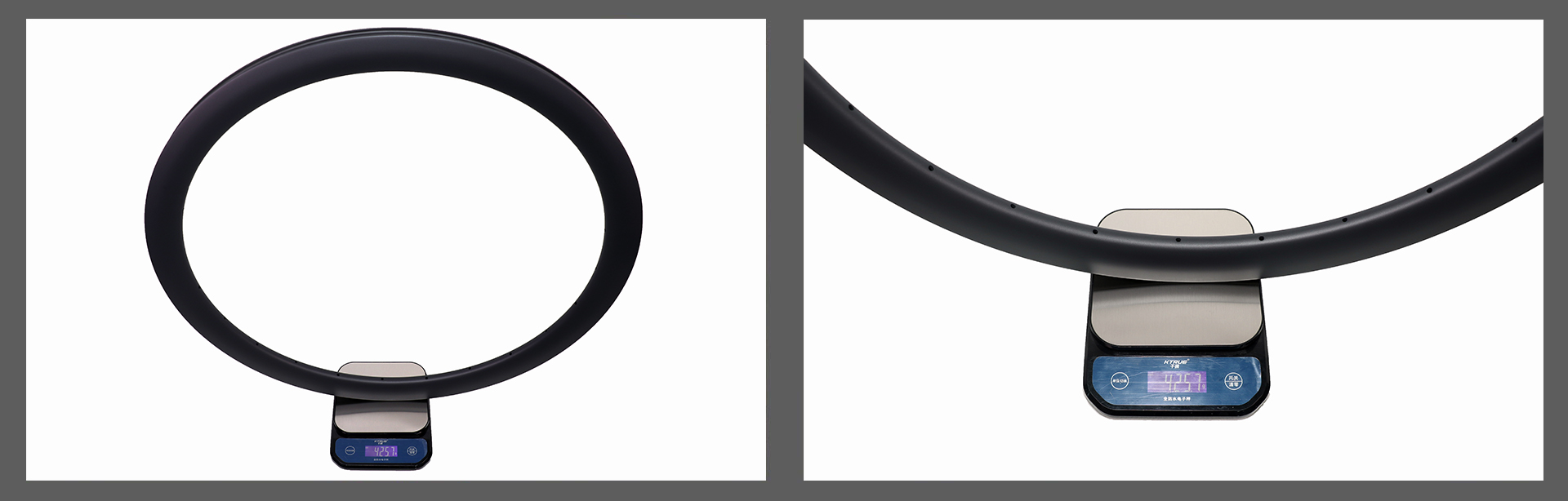

Lightweight

Features: Each rim weighs as little as 350g, achieving extreme weight reduction through high-performance carbon fiber and lightweight structural design.

Benefits: Reduced wheel moment of inertia for sharper acceleration response; reduced overall vehicle weight, reducing rider fatigue, making it particularly suitable for climbing and long training sessions.

High-Temperature Braking

Features: The rim's braking surface utilizes a special resin coating and heat dissipation structure to withstand the high temperatures generated by continuous braking.

Benefits: Prevents performance degradation or deformation caused by high temperatures, ensures stability and safety during long descents and high-speed braking, and extends rim life.

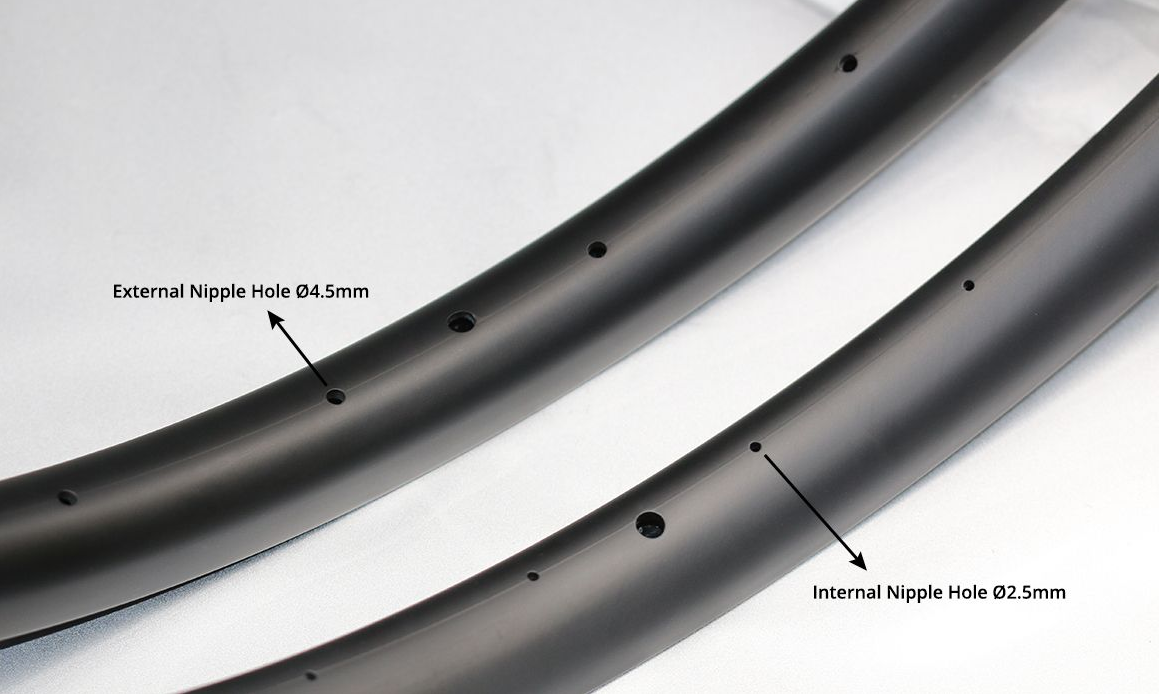

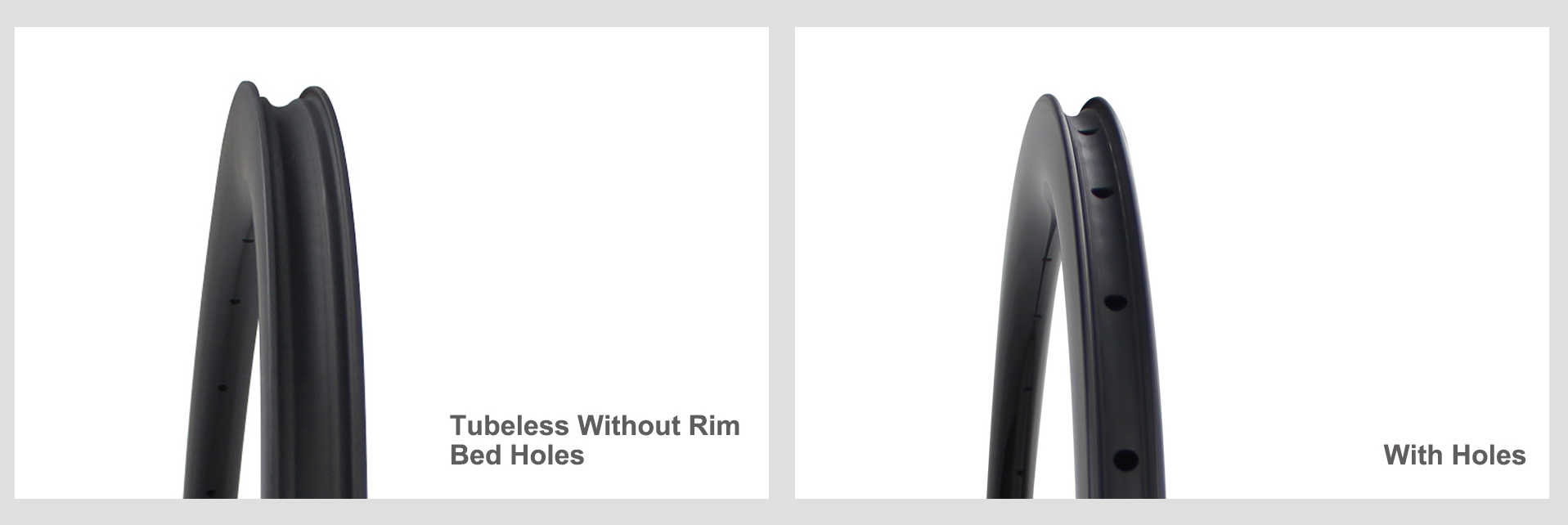

Customized Carbon Spoke Holes

Features: Customizes the number, position, and specifications of spoke holes to meet your needs, and is compatible with various lacing methods and carbon spoke systems.

Benefits: Meets personalized wheel assembly needs and adapts to various riding scenarios (such as racing and training); improves spoke tension distribution, further enhancing overall rim rigidity and durability.

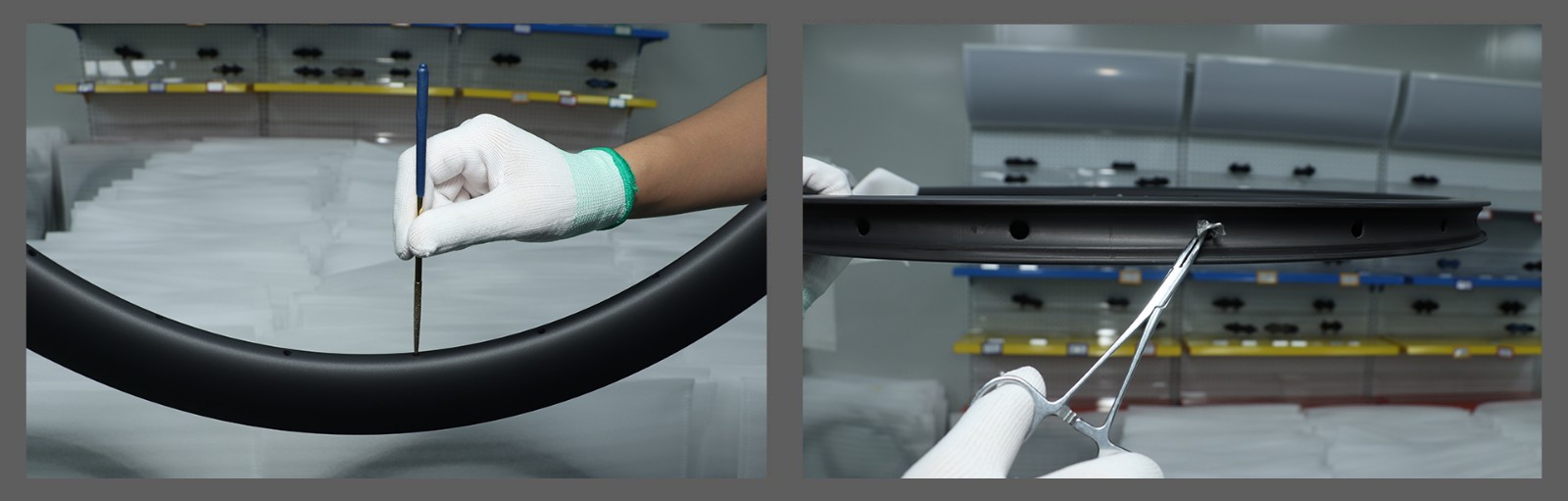

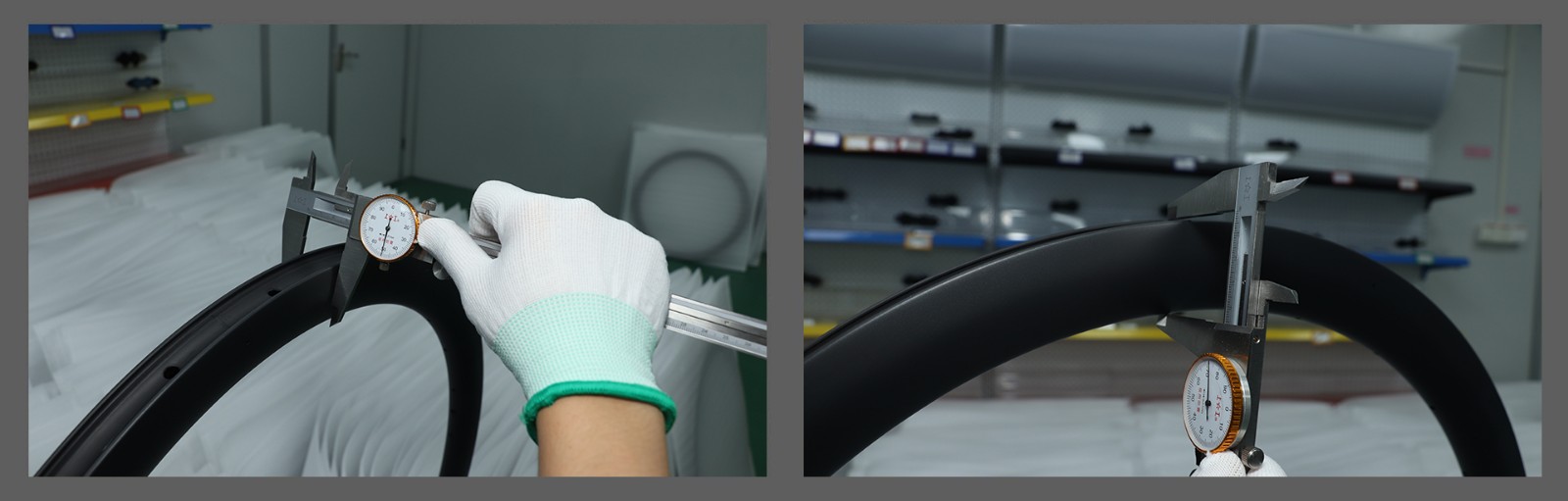

Strict Quality Control:

KOBIKE do 100% tire pressure(150 PSI), flatness(<0.2mm) and roundness(<0.2mm) inspections before shipping, also offering 2 years warranty for our carbon rims.

Aerodynamics

Features: The streamlined profile of 40mm height and 26mm outer width has been optimized in a wind tunnel to effectively reduce air resistance.

Benefits: Improves high-speed cruising efficiency and reduces wind resistance, making it particularly suitable for road racing and long-distance cycling, helping riders save energy and push their speed limits.

High Rigidity

Features: Utilizing Japanese Toray carbon fiber and proprietary layup technology, the fiber arrangement is precisely aligned with stress points, resulting in a structural strength far exceeding that of traditional aluminum alloy rims.

Benefits: Minimal deformation during acceleration and power application, improving power transmission efficiency; greater stability during cornering and climbing, reducing body roll and enhancing handling confidence.

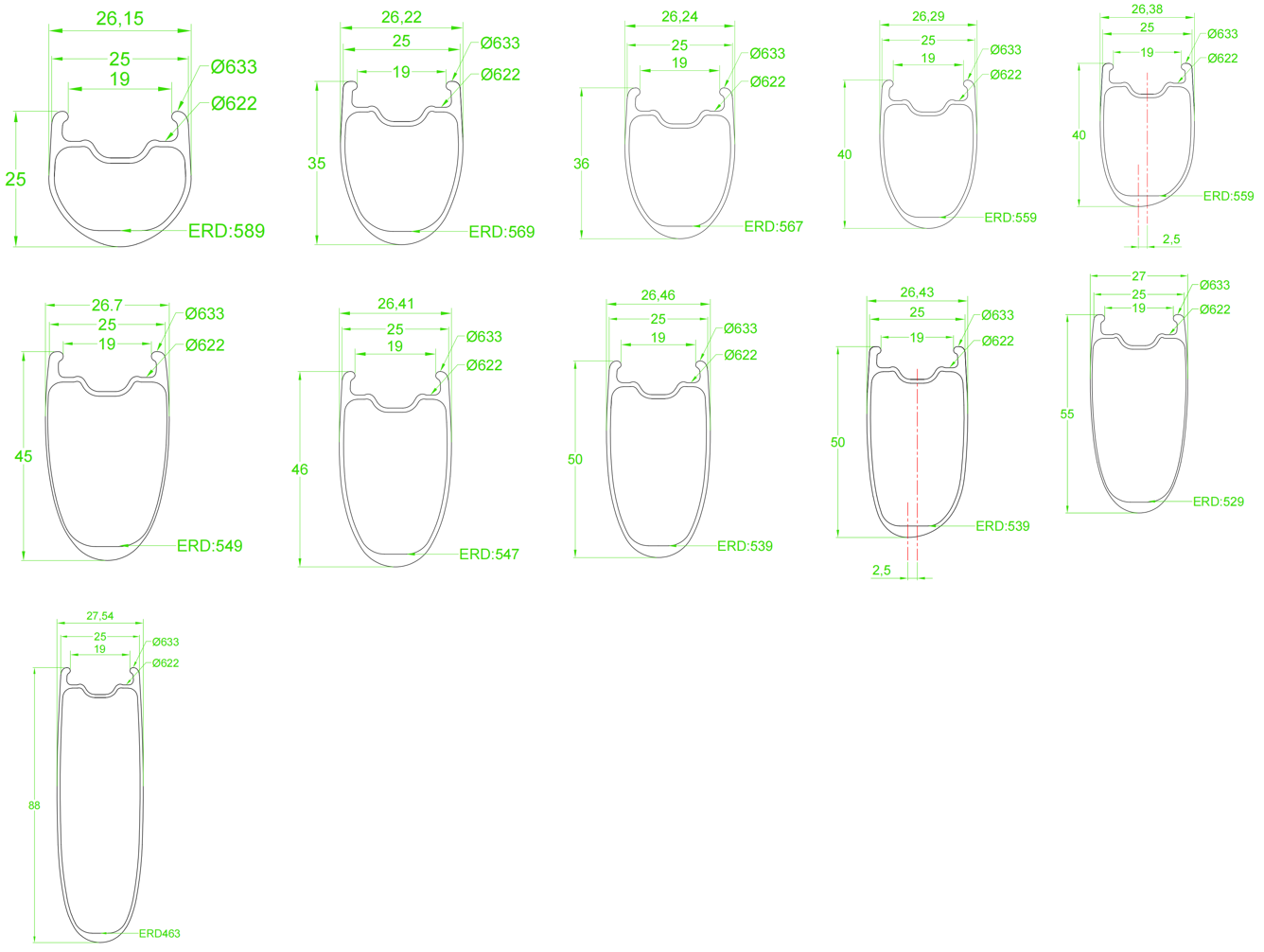

Spoke Hole Design

Normal Symmetrical Drilling

Features: Spoke holes are symmetrically spaced around the rim's center axis, with even spacing between holes. Suitable for traditional radial or cross-stitch lacing.

Advantages: Even spoke tension distribution, easy installation and commissioning, suitable for standard wheel assembly, ensuring structural stability during regular riding, and low maintenance.

Offset Drilling

Features: The drive-side spoke holes are offset 2-3mm inward of the rim, while the non-drive-side holes remain symmetrical. The spoke angle is optimized to match the hub flange width.

Advantages: Reduces spoke stress concentration, improves drive efficiency, and reduces rim deformation, especially during high power output. Suitable for competition-level wheels that require enhanced durability.

Application areas for the D45X26T carbon bicycle rim:

Grand Tours

Advantages of Tubular Rims: The 45mm height and 26mm outer width aerodynamic design are ideal for long-distance cruising on flat roads. The lightweight design reduces the burden of climbing, and the high rigidity ensures explosive power transmission during sprints, making it suitable for the rigors of multiple days of intense riding.

Classic Races

Advantages of Tubular Rims: The tight fit of the tubular tire and rim reduces tire deformation during bumps. The high-rigidity structure reduces the impact of road shock on handling, and the high-temperature braking design ensures reliable braking in rainy or muddy conditions.

Time Trials

Advantages of Tubular Rims: The wind-tunnel-optimized streamlined profile minimizes wind resistance, and the offset drilling design improves spoke force efficiency. Combined with the low rolling resistance of tubular tires, this helps riders achieve shorter finishing times over a given distance.

Continental Races

Advantages of Tubular Rims: Symmetrical drilling design facilitates unified team maintenance, customizable paint jobs can meet team branding needs, and balanced aerodynamics and lightweight performance are suitable for a variety of race stages.

Track Racing

Advantages of Tubular Rims: High-modulus carbon fiber construction provides a highly rigid structure that instantly responds to rider acceleration. The 45mm rim depth maintains a stable airflow pattern at high speeds, reducing unnecessary energy loss.

| Model | Weight (Gram) | Brake System | Inner Width | Outer Width | Depth | Available Appearance | Available Spoke Hole Counts |

R25X26TL-NL | 390±15g | Rim/Disc Brake | 19mm | 26mm | 25mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

R25X26TL-UL | 365/330±15g | Rim/Disc Brake | 19mm | 26mm | 25mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D25X26TL-SL | 360±15g | Disc Brake | 19mm | 26mm | 25mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

R35X26TL-NL | 435±15g | Rim/Disc Brake | 19mm | 26mm | 35mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

R35X26TL-UL | 410/350±15g | Rim/Disc Brake | 19mm | 26mm | 35mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| D35X26TL-SL | 400±15g | Disc Brake | 19mm | 26mm | 35mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R36X26TL-NL | 435/420±15g | Rim/Disc Brake | 19mm | 26mm | 36mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R36X26TL-UL | 410/350±15g | Rim/Disc Brake | 19mm | 26mm | 36mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| D36X26TL-SL | 400±15g | Disc Brake | 19mm | 26mm | 36mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R40X26TL-NL | 455/440±15g | Rim/Disc Brake | 19mm | 26mm | 40mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R40X26TL-UL | 435/375±15g | Rim/Disc Brake | 19mm | 26mm | 40mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| D40X26TL-SL | 420±15g | Disc Brake | 19mm | 26mm | 40mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| RA40X26TL-NL | 455/440±15g | Rim/Disc Brake | 19mm | 26mm | 40mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| RA40X26TL-UL | 435/375±15g | Rim/Disc Brake | 19mm | 26mm | 40mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| DA40X26TL-SL | 420±15g | Disc Brake | 19mm | 26mm | 40mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R45X26TL-NL | 475/460±15g | Rim/Disc Brake | 19mm | 26mm | 45mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R45X26TL-UL | 455/390±15g | Rim/Disc Brake | 19mm | 26mm | 45mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| D45X26TL-SL | 440±15g | Disc Brake | 19mm | 26mm | 45mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R45X26T-UL | 320/330 | Rim/Disc Brake | - | 26mm | 45mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R46X26TL-NL | 475/460±15g | Rim/Disc Brake | 19mm | 26mm | 46mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R46X26TL-UL | 455/390±15g | Rim/Disc Brake | 19mm | 26mm | 46mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| D46X26TL-SL | 440±15g | Disc Brake | 19mm | 26mm | 46mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R50X26TL-NL | 495/480±15g | Rim/Disc Brake | 19mm | 26mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R50X26TL-UL | 475/420±15g | Rim/Disc Brake | 19mm | 26mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| D50X26TL-SL | 460±15g | Disc Brake | 19mm | 26mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| RA50X26TL-NL | 495/480±15g | Rim/Disc Brake | 19mm | 26mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| RA50X26TL-UL | 475/420±15g | Rim/Disc Brake | 19mm | 26mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| DA50X26TL-SL | 460±15g | Disc Brake | 19mm | 26mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R55X26TL-NL | 525/500±15g | Rim/Disc Brake | 19mm | 26mm | 55mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R55X26TL-UL | 405/440±15g | Rim/Disc Brake | 19mm | 26mm | 55mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| D55X26TL-SL | 480±15g | Disc Brake | 19mm | 26mm | 55mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R88X27TL-NL | 660/640±15g | Rim/Disc Brake | 19mm | 26mm | 88mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R88X27TL-UL | 640/620±15g | Rim/Disc Brake | 19mm | 26mm | 88mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

100% Customizable

Customized Weaves & Finishes:

Customized Laser Engraving Brake Track:

Customized Holes:

Weight Check:

Clean burrs & residues

Rim Diameters Check:

Cleaning & Packing

We have been in carbon bicycle production industry since the year of 2015, so 10 years history and experiences.

100 workers, 30 management, 20 Engineers, 10 Sales.

Carbon bicycle rims, carbon spokes, carbon wheels, cranks and other carbon bicycle components.

Our factory area is 2500 square meters, with 2 production lines, one wheel building line.

10.000 pcs/month for carbon rims, 100.000 pcs/month for carbon spokes, 10.000 pcs/month for other carbon bicycle components like cranks, handlebars, thru axles etc.

10-15 days for carbon rims(100-200 pcs), 7-10 days for carbon spokes, 25-30 days for carbon wheels.

It depend on the product models, quantities and and other factors, takes carbon rim for example, price generate from 80-130 USD per piece.

2 years for carbo rims and wheels, 1 year for carbon spokes.

We focus on OEM/ODM service for customers mainly on Europe and American markets.

We have signed confidential agreement with our big OEM customers, so not allow to tell, but the big brands from Europe and America.

Our factory locates in Xiamen, China.