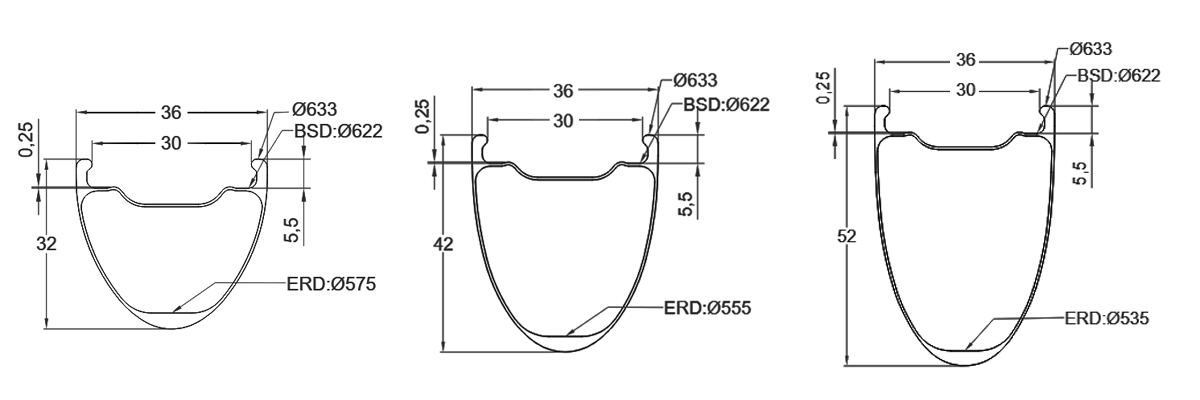

KOIBIKE leverages its in-house expertise to create the G52X36TL-UL gravel rims, designed specifically for challenging conditions like gravel roads and mixed terrain. The rims are constructed from high-modulus carbon fiber, molded using a low-temperature curing process. Their 52mm aerodynamic profile reduces crosswind interference common on gravel roads, while their 36mm outer width provides rigid support for wide tires. A tire pressure range of 30-60 PSI covers the demands of both paved roads and gravel beaches. The 455±15g weight maintains a 125kg weight limit while achieving lightweight advantages. A variety of paint finishes, including full matte and 70% gloss matte, satisfy aesthetic needs while enhancing surface wear resistance. Our factory's mature industrial chain enables us to meet the needs of B2B customers for mass customization, with complete control from material cutting to finished product inspection.

Wide Terrain Compatibility:

The 36mm outer width accommodates tires ranging from 33-72cm, providing stable support for tires ranging from narrow road tires to wide gravel tires. With a tire pressure adjustment range of 20-60°, you can set higher pressures for reduced drag on paved roads and lower pressures for enhanced cushioning on gravel roads, providing a one-stop solution for transitioning between mixed terrain.

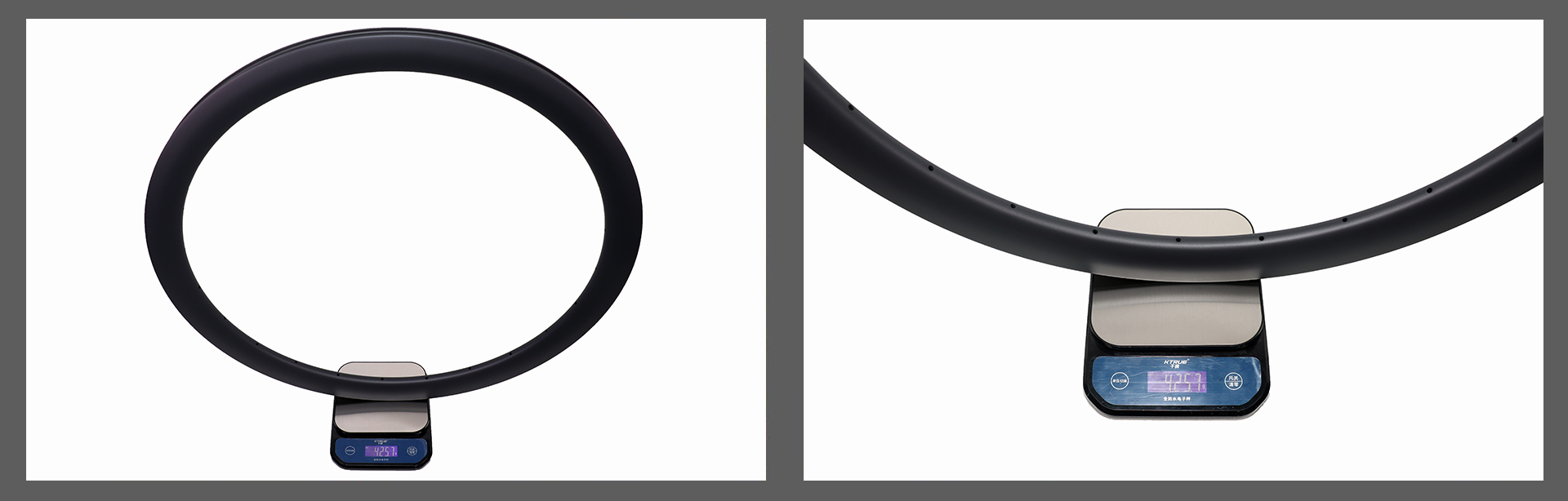

Lightweight and balanced:

The 455±15g weight is achieved thanks to the carbon fiber monocoque and hollow design, making it 12% lighter than traditional gravel rims. Furthermore, the high-modulus carbon fiber achieves a shear strength of 4.2GPa. With a rider weight of 125kg, radial rim deflection is kept to within 0.2mm, ensuring both flexibility and durability.

Aerodynamically optimized:

The 52mm-high section features a curved leading edge. Wind tunnel testing shows that at a 15° crosswind, drag is 8% lower than a 40mm rim, making it ideal for long paved sections interspersed with gravel roads, reducing exertion.

Multiple paint options:

The matte and smoked black finishes utilize a ceramic composite coating that reduces surface friction by 30% compared to conventional coatings, minimizing gravel scratches. The paint-free process reveals the original carbon fiber grain, balancing lightweight design with an industrial aesthetic to meet diverse style needs.

Safety Weight Limit Design:

Targeting riders under the 125kg weight limit, the rim utilizes thickened carbon fiber layers in key areas, and stress distribution treatment is applied around the spoke holes. This improves structural stability by 15% compared to standard rims under load and the impact of rough terrain.

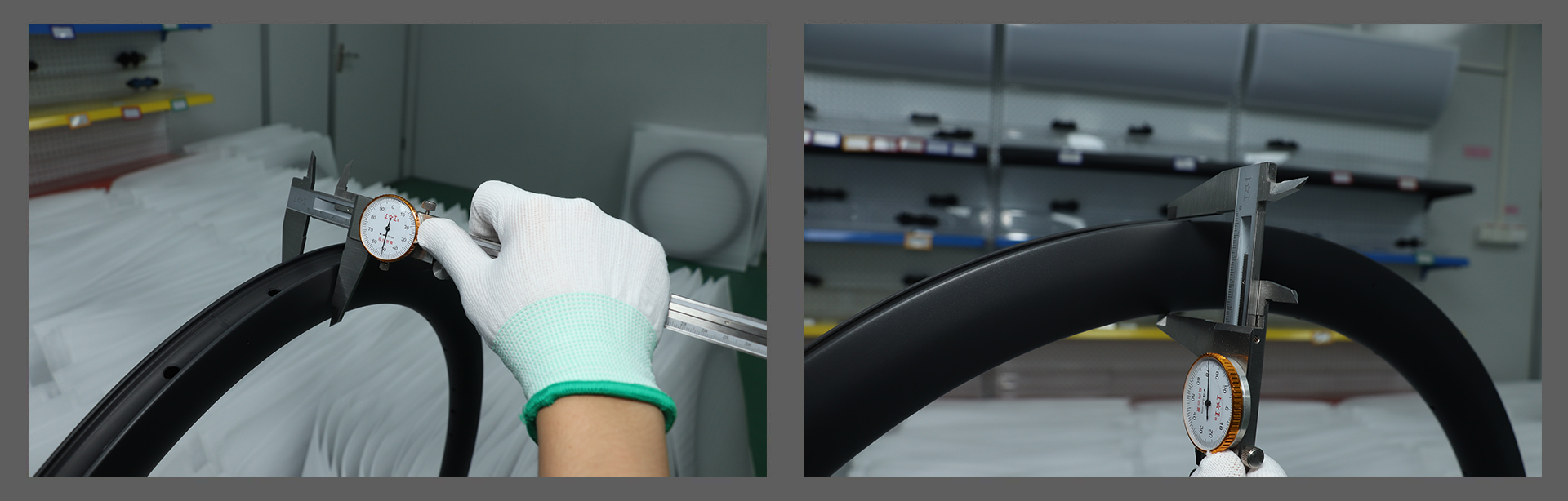

Strict Quality Control:

KOBIKE do 100% tire pressure(150 PSI), flatness(<0.2mm) and roundness(<0.2mm) inspections before shipping, also offering 2 years warranty for our carbon rims.

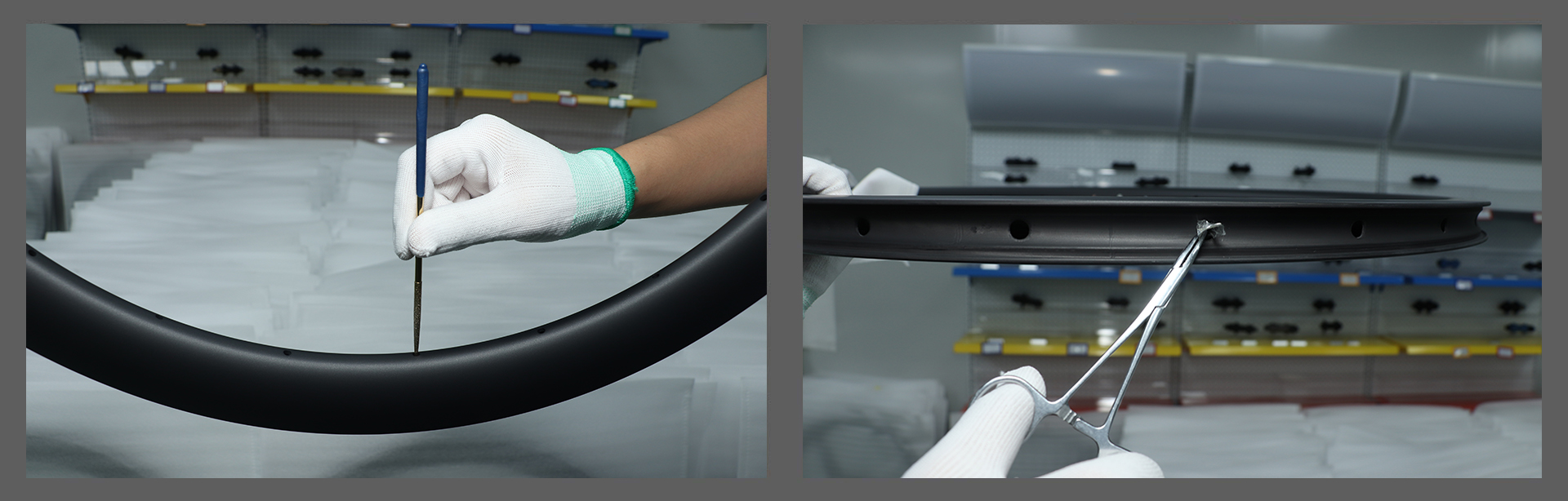

Spoke Hole Stress Optimization:

Evenly spaced spoke holes are embedded with bushings, and combined with a multi-layer carbon fiber wrapping, the spoke hole's tensile strength reaches 300kg, a 25% increase over bushingless designs, preventing spoke loosening caused by bumpy gravel roads.

Bead Seal:

A dual-step seal groove on the inside of the rim ensures 24-hour air leakage of ≤1psi at a high tire pressure of 60psi. This provides greater stability than a single-groove design and accommodates a wide range of tire pressures.

Aerodynamic Section:

The 52mm-tall rim features a teardrop-shaped design, with the trailing edge tapering to 15mm to minimize airflow separation and maintain aerodynamic efficiency in the turbulent conditions common on gravel roads.

Painting Details:

The full matte finish utilizes matte particle filling technology, resulting in a surface roughness of ≤0.8μm (Ra), making it highly dust-resistant. The smoked black finish is achieved through carbon tube dyeing, resulting in a coating thickness of only 0.03mm, adding no additional weight.

Weight-Restricted Reinforced Area:

The carbon fiber stacking density at the flange where the rim meets the hub is increased by 30%, forming a circular reinforcement band. At a load of 125kg, stress levels here are reduced by 20% compared to standard areas, extending service life.

Application areas for the G52X36TL carbon bicycle rim:

Mixed Gravel:

Suitable for tires ranging from 33-72cm and a wide range of tire pressures, it easily handles mixed terrain, including gravel roads, sandy dirt roads, and country dirt roads. It is an ideal choice for gravel enthusiasts exploring uncharted terrain.

Long-Distance Adventure Riding:

Its lightweight design and 125kg weight limit allow it to carry additional loads like camping gear. Its 52mm aerodynamic height reduces fatigue over long distances, making it ideal for multi-day, cross-country adventures.

Gravel Racing:

In gravel racing, the wide tire's adaptability and aerodynamic advantages combine to accelerate on paved sections and maintain stability on gravel sections, helping competitors improve their performance.

Urban Commuting:

Combining road efficiency with light off-road capability, you can switch to narrower tires for speed on daily commutes and wider tires for weekend leisure time on suburban gravel roads, creating a versatile vehicle.

High-End Vehicle Competitiveness:

As a core component of high-end gravel models, its diverse paint options and performance advantages enhance the overall vehicle's competitiveness, attracting consumers who seek personalized and versatile features.

| Model | Weight(Gram) | Inner Width | Outer Width | Depth | Brake System | Available Appearance | Available Spoke Hole Counts |

| G32X36TL-SL | 390±15 | 30mm | 36mm | 32mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| G32X36TL-UL | 370±15 | 30mm | 36mm | 32mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| G42X36TL-SL | 425±15 | 30mm | 36mm | 42mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| G42X36TL-UL | 405±15 | 30mm | 36mm | 42mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| G52X36TL-SL | 465±15 | 30mm | 36mm | 52mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| G52X36TL-UL | 445±15 | 30mm | 36mm | 52mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

The above parameters are for reference only, please consult our engineers for specific technical parameters.

100% Customizable

Customized Weaves & Finishes:

Customized Holes:

![]()

Weight Check:

Clean burrs & residues:

Rim Diameters Check:

Cleaning:

Packing:

We have been in carbon bicycle production industry since the year of 2015, so 10 years history and experiences.

100 workers, 30 management, 20 Engineers, 10 Sales.

Carbon bicycle rims, carbon spokes, carbon wheels, cranks and other carbon bicycle components.

Our factory area is 2500 square meters, with 2 production lines, one wheel building line.

10.000 pcs/month for carbon rims, 100.000 pcs/month for carbon spokes, 10.000 pcs/month for other carbon bicycle components like cranks, handlebars, thru axles etc.

10-15 days for carbon rims(100-200 pcs), 7-10 days for carbon spokes, 25-30 days for carbon wheels.

It depend on the product models, quantities and and other factors, takes carbon rim for example, price generate from 80-130 USD per piece.

2 years for carbo rims and wheels, 1 year for carbon spokes.

We focus on OEM/ODM service for customers mainly on Europe and American markets.

We have signed confidential agreement with our big OEM customers, so not allow to tell, but the big brands from Europe and America.

Our factory locates in Xiamen, China.