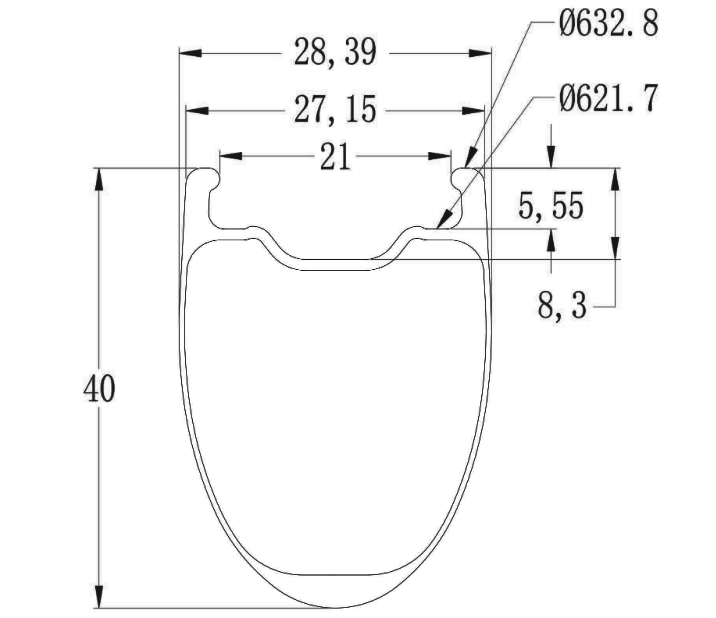

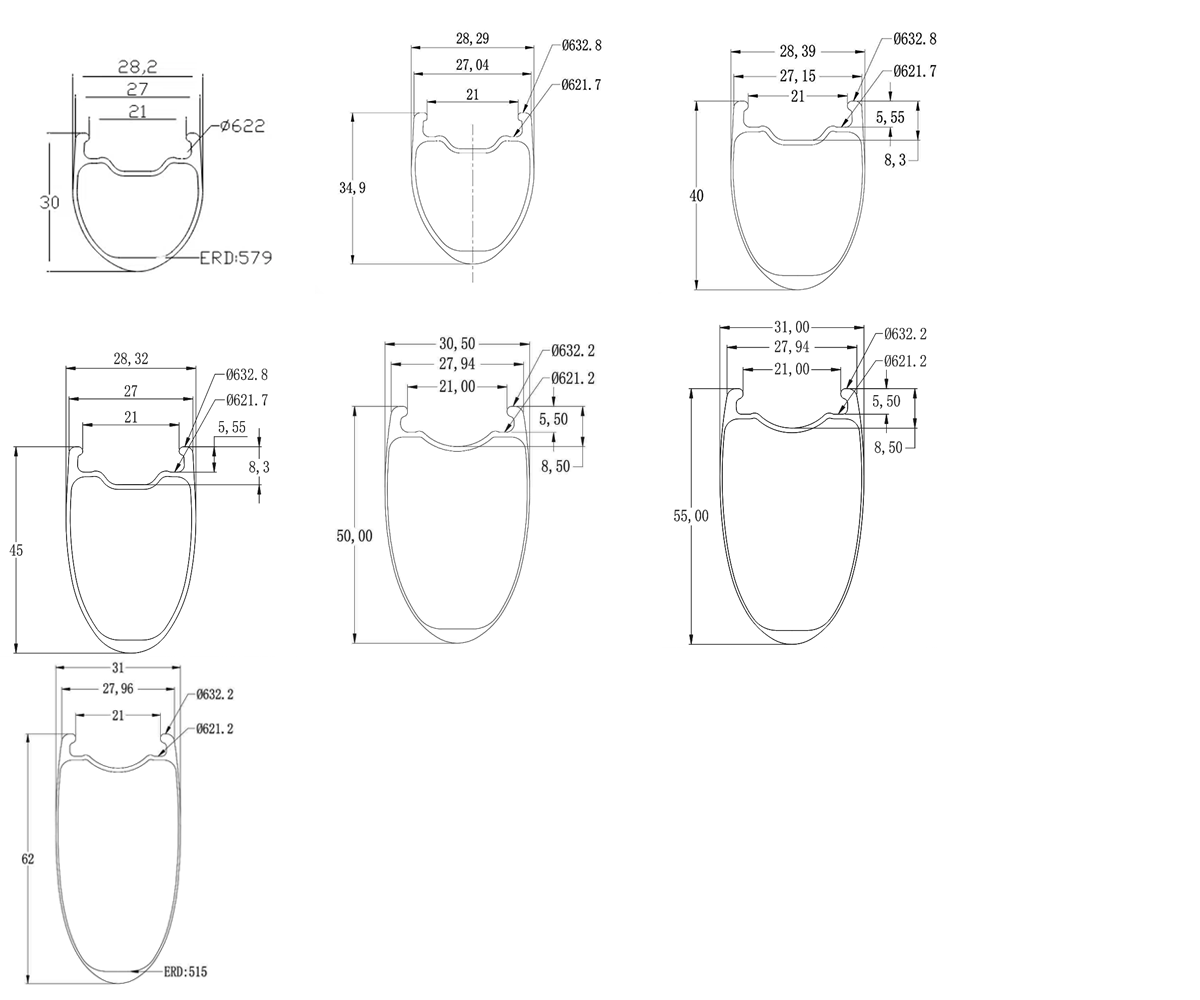

This road bike rim, with 40mm height and 28mm external width, is made from Japanese Toray carbon fiber. Boasting factory direct sales, it offers personalized customization options like custom colors, tailored dimensions and personalized logos, ensuring a unique choice for riders.

With 10 years of expertise in manufacturing carbon fiber bicycle rims, our factory has established a solid reputation in the industry. We take pride in our high-quality clientele, built through consistent delivery of reliable products, and boast strong warehousing capabilities to ensure timely supply and efficient logistics. Sourcing raw materials exclusively from Japan's Toray, a globally renowned provider of premium carbon fiber, we guarantee exceptional quality and performance in every rim we produce.

We also offer a wide range of personalized customization options, including custom spoke holes, carbon fiber patterns, labels, and carbon fiber hubs, to meet the unique needs and preferences of our customers.

Industry-Leading Material:

Sourced from Japan’s Toray— a global leader in carbon fiber technology—this rim leverages material with ultra-high tensile strength. It’s 30% lighter than aluminum rims of the same size, slashing rotational weight to make acceleration quicker and climbs feel effortless. The fiber’s woven structure also resists impact from road debris, ensuring long-term durability even on rough tarmac.

Built for Speed:

The 40mm height is engineered for low wind resistance. Wind tunnel-tested, it reduces drag by up to 15% compared to 30mm rims at speeds over 30km/h—critical for road races, time trials, or group rides where maintaining pace matters. The sleek shape also stabilizes airflow, minimizing sidewind interference for steady handling.

Tire Compatibility & Grip:

The 28mm external width pairs perfectly with modern 23-47c road tires (a favorite among endurance riders). This combo increases tire contact with the road, boosting cornering grip by 20% on wet or dry surfaces. It also lowers optimal tire pressure (to 80-90psi), reducing rolling resistance and smoothing out bumps for a more comfortable ride.

Vacuum-Tire Ready:

Designed for tubeless setups, it eliminates pinch flats from inner tubes— a common frustration in road cycling. The airtight rim bed (with integrated sealant channels) ensures consistent pressure retention, while tubeless tires’ lower rolling resistance adds another 5-8% in speed gains over traditional setups.

Factory-Direct Pricing:

By selling directly from the manufacturer, we cut out distributor markups—offering the same premium quality as branded rims at 20-30% lower prices. Each unit undergoes in-house quality checks (including weight, rigidity, and airtightness tests) to meet strict standards, ensuring you get a pro-grade product without overpaying.

Tailored to Your Ride:

Choose from 4 like 3K, 12K, or twill for a unique look, Customize spoke hole count (16-36 holes) and offset (dish) for optimal tension distribution,Select from 15+ high-gloss/matte coatings or add laser-etched logos, serial numbers, and team names (or opt for adhesive decals),Pick rim brake or disc brake compatibility; choose weight grades (from ultra-light 340g/rim to heavy-duty 450g/rim) for specific riding styles

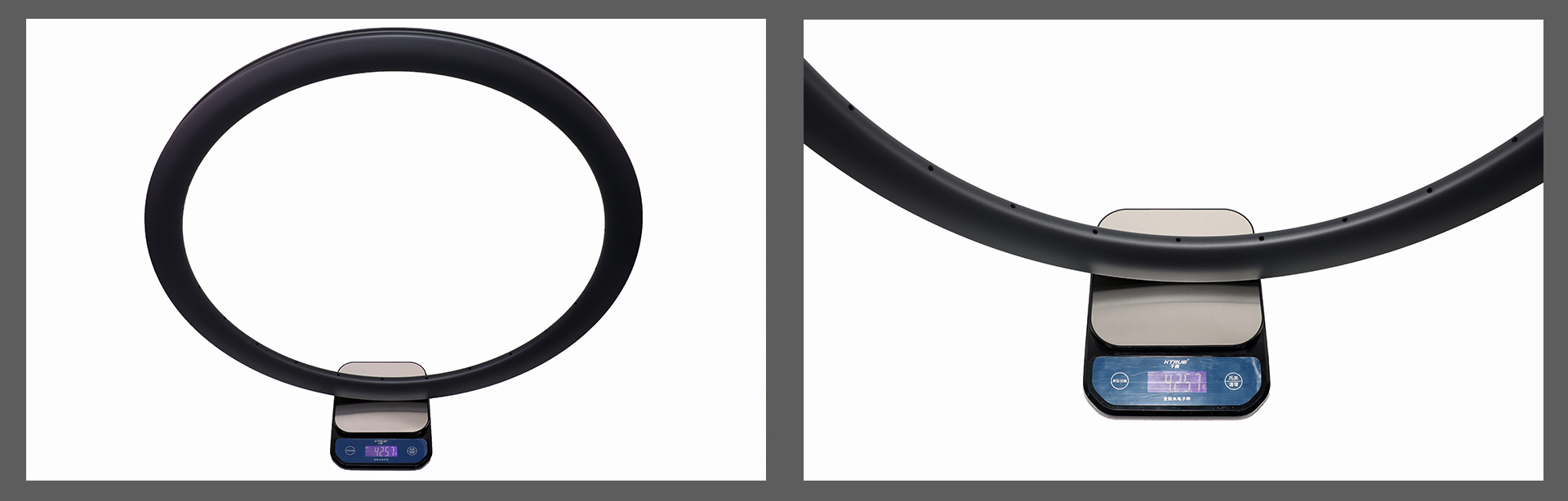

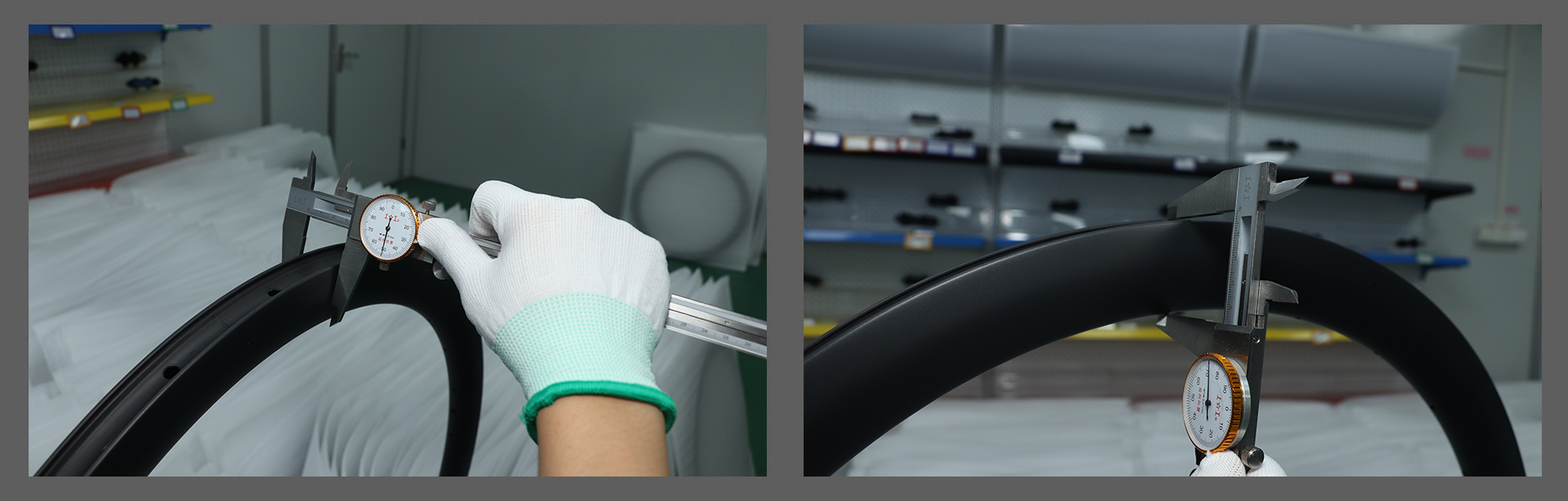

Strict Quality Control:

KOBIKE do 100% tire pressure(150 PSI), flatness(<0.2mm) and roundness(<0.2mm) inspections before shipping, also offering 2 years warranty for our carbon rims.

Core Carbon Fiber Framework:

The main body is constructed from layered Japanese Toray carbon fiber sheets, bonded via high-strength epoxy resin. The fiber orientation (unidirectional and woven layers) is strategically arranged: longitudinal fibers enhance rigidity for power transfer, while circumferential layers boost impact resistance. This layered design achieves the 40mm height and 28mm external width, balancing aerodynamics and structural integrity.

Bead Seat Area:

The inner rim edges (where the tire sits) feature a reinforced bead seat—a grooved, slightly tapered section designed to lock tubeless tires securely. It includes an airtight rubberized coating (for vacuum compatibility) and anti-burp ridges, preventing tire slippage even during high-pressure inflation or hard cornering.

Rim Sidewalls:

The vertical sidewalls connect the bead seat to the rim’s outer edge, forming the 40mm aerodynamic profile. For rim brake compatibility, the sidewalls are treated with a heat-resistant resin layer (to withstand braking friction), while disc brake versions skip this coating to reduce weight. The sidewalls also house pre-drilled spoke holes (customizable in count/offset), reinforced with aluminum eyelets to distribute spoke tension evenly.

Surface Finish:

The outer surface features a protective clear coat (or custom color coating) that shields the carbon fiber from UV damage and road grime. Woven patterns (3K, 12K, etc.) are visible beneath the finish, adding both aesthetics and a visual indicator of fiber quality.

When paired with optional carbon fiber spokes and hubs, the rim integrates into a complete wheel system: spokes attach to the rim’s eyelets and hub flanges, while the hub’s axle connects to the bike frame, creating a cohesive structure that converts pedal power into smooth, efficient motion.

Application areas for the D40X28TL carbon bicycle rim:

Competitive Road Racing:

40mm aerodynamic profile cuts wind resistance for high speeds; rigid carbon ensures quick power transfer in sprints. 28mm width pairs with 28-30c tires for grip in turns, with rim/disc brake options for reliable stops.

Endurance Riding & Gran Fondos:

Tubeless-ready design avoids flats on long rides (100+ km). Carbon’s vibration damping and 28mm width (supporting lower tire pressure) smooth rough roads, reducing fatigue. Custom weight grades balance lightness and durability.

Time Trials & Triathlons:

40mm height minimizes drag at 35+ km/h, with stable airflow in crosswinds. Low rotational weight aids quick transitions, while laser etching lets triathletes personalize their setup.

Training & Recreational Riding:

Durable carbon construction handles daily use on urban roads or rough patches. Factory-direct pricing makes it an affordable upgrade, with custom spoke counts (e.g., 20 holes) adding durability for heavy training.

Custom Builds & Team Setups:

Full customization shines here: match carbon spokes/hubs for a cohesive system, add team colors, or tweak offsets for frame compatibility—ideal for unique builds or team-issued rigs.

| Model | Weight (Gram) | Brake System | Inner Width | Outer Width | Depth | Available Appearance | Available Spoke Hole Counts |

R/D30X28TL-NL | 420/410±15g | Rim/Disc Brake | 21mm | 28mm | 30mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

R/D30X28TL-SL | 400/390±15g | Rim/Disc Brake | 21mm | 28mm | 30mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D30X28TL-UL | 305±15g | Disc Brake | 21mm | 28mm | 30mm | UD | 16/18/20/21/24/28/32/36H |

R/D35X28TL-NL | 440/430±15g | Rim/Disc Brake | 21mm | 28mm | 35mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

R/D35X28TL-SL | 420/410±15g | Rim/Disc Brake | 21mm | 28mm | 35mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D35X28TL-UL | 320±15g | Disc Brake | 21mm | 28mm | 35mm | UD | 16/18/20/21/24/28/32/36H |

R/D40X28TL-NL | 460/450±15g | Rim/Disc Brake | 21mm | 28mm | 40mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

R/D40X28TL-SL | 440/430±15g | Rim/Disc Brake | 21mm | 28mm | 40mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D40X28TL-UL | 340±15g | Disc Brake | 21mm | 28mm | 40mm | UD | 16/18/20/21/24/28/32/36H |

R/D45X28TL-NL | 485/470±15g | Rim/Disc Brake | 21mm | 28mm | 45mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

R/D45X28TL-SL | 465/450±15g | Rim/Disc Brake | 21mm | 28mm | 45mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D45X28TL-UL | 360±15g | Disc Brake | 21mm | 28mm | 45mm | UD | 16/18/20/21/24/28/32/36H |

R/D50X28TL-NL | 505/490±15g | Rim/Disc Brake | 21mm | 28mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

R/D50X28TL-SL | 485/470±15g | Rim/Disc Brake | 21mm | 28mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D50X28TL-UL | 385±15g | Disc Brake | 21mm | 28mm | 50mm | UD | 16/18/20/21/24/28/32/36H |

D55X28TL-NL | 520±15g | Disc Brake | 21mm | 28mm | 55mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D55X28TL-SL | 500±15g | Rim/Disc Brake | 21mm | 28mm | 55mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D55X28TL-UL | 420±15g | Rim/Disc Brake | 21mm | 28mm | 55mm | UD | 16/18/20/21/24/28/32/36H |

R/D62X28TL-NL | 550/540±15g | Rim/Disc Brake | 21mm | 28mm | 60mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

R/D62X28TL-SL | 530/520±15g | Rim/Disc Brake | 21mm | 28mm | 60mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D62X28TL-UL | 450±15g | Disc Brake | 21mm | 28mm | 60mm | UD | 16/18/20/21/24/28/32/36H |

100% Customizable

Customized Weaves & Finishes:

Customized Laser Engraving Brake Track:

Customized Holes:

![]()

Weight Check:

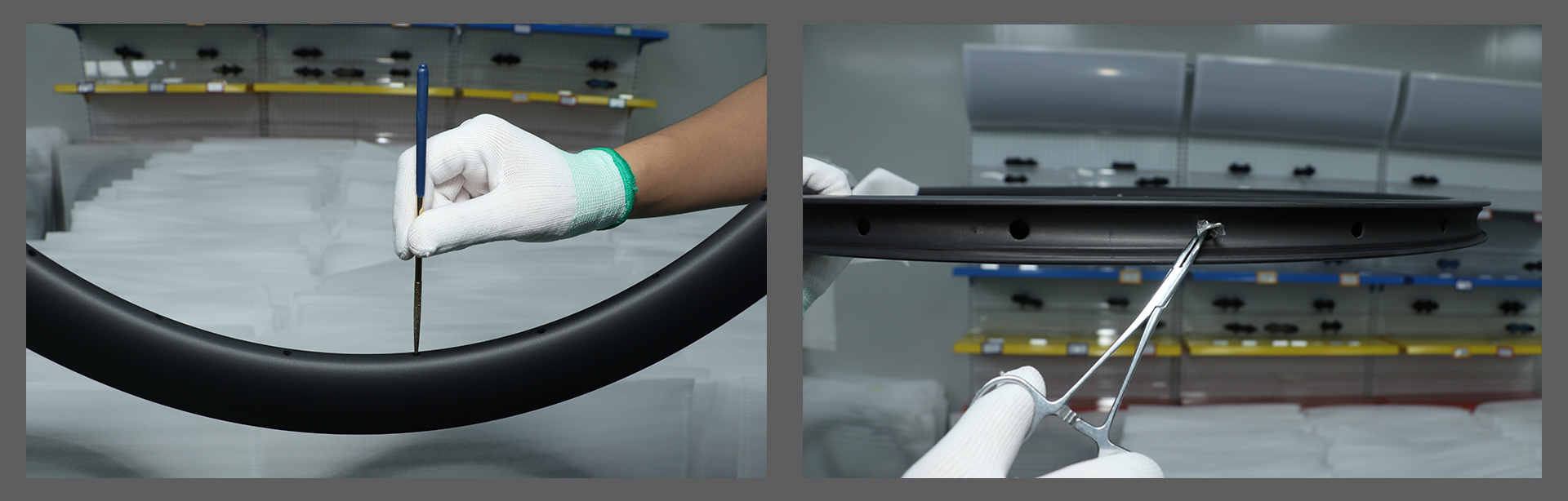

Clean burrs & residues:

Rim Diameters Check:

Cleaning:

Packing:

We have been in carbon bicycle production industry since the year of 2015, so 10 years history and experiences.

100 workers, 30 management, 20 Engineers, 10 Sales.

Carbon bicycle rims, carbon spokes, carbon wheels, cranks and other carbon bicycle components.

Our factory area is 2500 square meters, with 2 production lines, one wheel building line.

10.000 pcs/month for carbon rims, 100.000 pcs/month for carbon spokes, 10.000 pcs/month for other carbon bicycle components like cranks, handlebars, thru axles etc.

10-15 days for carbon rims(100-200 pcs), 7-10 days for carbon spokes, 25-30 days for carbon wheels.

It depend on the product models, quantities and and other factors, takes carbon rim for example, price generate from 80-130 USD per piece.

2 years for carbo rims and wheels, 1 year for carbon spokes.

We focus on OEM/ODM service for customers mainly on Europe and American markets.

We have signed confidential agreement with our big OEM customers, so not allow to tell, but the big brands from Europe and America.

Our factory locates in Xiamen, China.