This carbon fiber BMX rim, crafted by a factory with 10 years of expertise, blends lightweight performance and customization.

Weighing just 320-355g, it features a 50mm height for aerodynamics and 25mm width for stable tubeless tire fit, ideal for BMX dynamics. The tubeless design reduces punctures and adapts to varied terrains.

Our decade-long experience ensures top-tier carbon quality, strict quality checks (99.99% pass rate), and flexible customization (colors, engravings). Factory-direct supply guarantees value and responsive service.

Perfect for commuting, racing, or custom builds.

Material Performance Advantages:

Crafted from high-quality carbon fiber, each rim weighs only 320-355g, which is significantly lighter than traditional aluminum alloy rims. This effectively reduces riding inertia, enabling quicker acceleration and easier climbing. Meanwhile, the carbon fiber material boasts excellent impact resistance and durability, capable of withstanding the test of complex road conditions for a long time.

Design Highlights:

The 50mm rim height has been meticulously optimized to effectively reduce air resistance and enhance aerodynamic performance, making it suitable for speed-oriented riding scenarios. The 25mm outer width design strengthens the fit with tubeless tires, improves stability and grip when cornering, perfectly adapts to the sport characteristics of BMX bikes, and makes riding control more precise.

Tubeless Compatibility Advantages:

Supports tubeless tire systems, achieving good airtightness without inner tubes, which greatly reduces the risk of punctures and blowouts, and minimizes unexpected interruptions during riding. Additionally, tubeless tires can adapt to different road conditions by adjusting tire pressure: they provide better cushioning on rough roads and reduce rolling resistance on flat roads, balancing comfort and riding efficiency.

Customization Service Advantages:

Offers a wide range of personalized customization options. The rim's color, pattern, laser engraving and other details can be customized according to user needs, meeting cyclists' pursuit of exclusive equipment and making each rim unique, highlighting the user's unique taste and style.

Production and Supply Advantages:

Directly supplied by manufacturers with 10 years of professional production experience, they have mature and stable production processes and strict quality control systems. From material selection to finished product inspection, there are standardized processes to ensure the quality consistency and reliability of each rim, with a factory pass rate of over 99.99%. The factory direct sales model eliminates intermediate links, not only providing products at more competitive prices, but also ensuring stable supply and more timely and efficient after-sales responses.

Strict Quality Control:

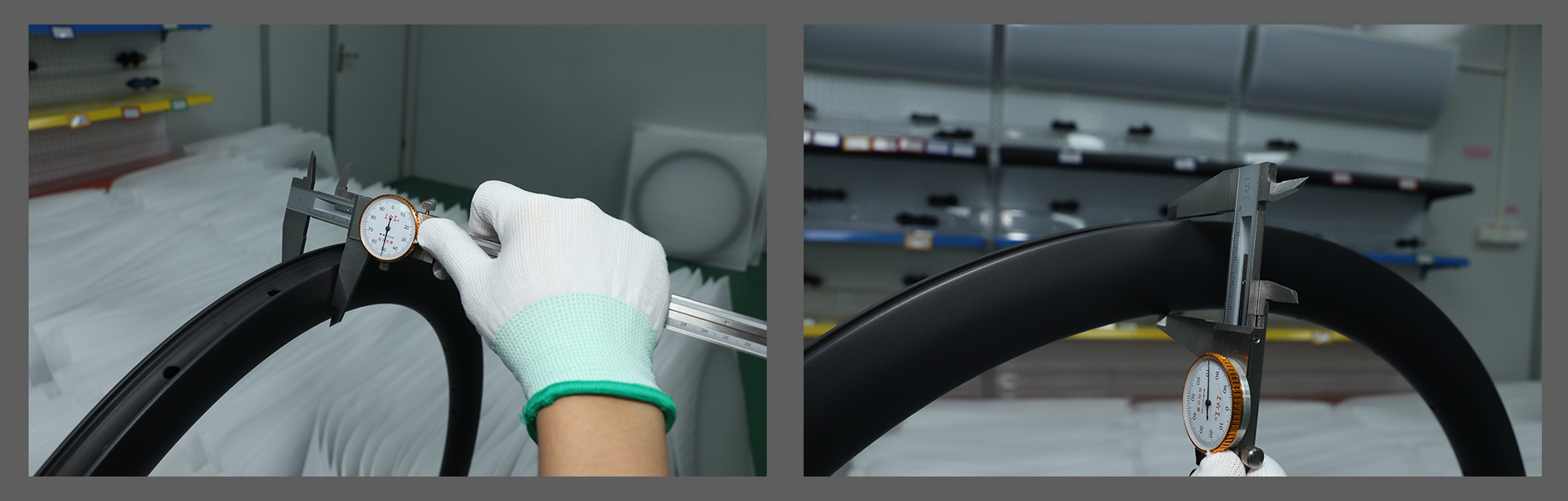

KOBIKE do 100% tire pressure(150 PSI), flatness(<0.2mm) and roundness(<0.2mm) inspections before shipping, also offering 2 years warranty for our carbon rims.

Material Composition:

High-modulus carbon fiber cloth is used as the core raw material, formed through multi-layer precision cutting and directional lamination processes. The fiber arrangement direction is optimized according to the stress characteristics of the rim, ensuring that while achieving lightweight (320-355g), the overall structural strength and torsional resistance are enhanced. The outer layer is treated with a special coating to improve wear resistance and corrosion resistance.

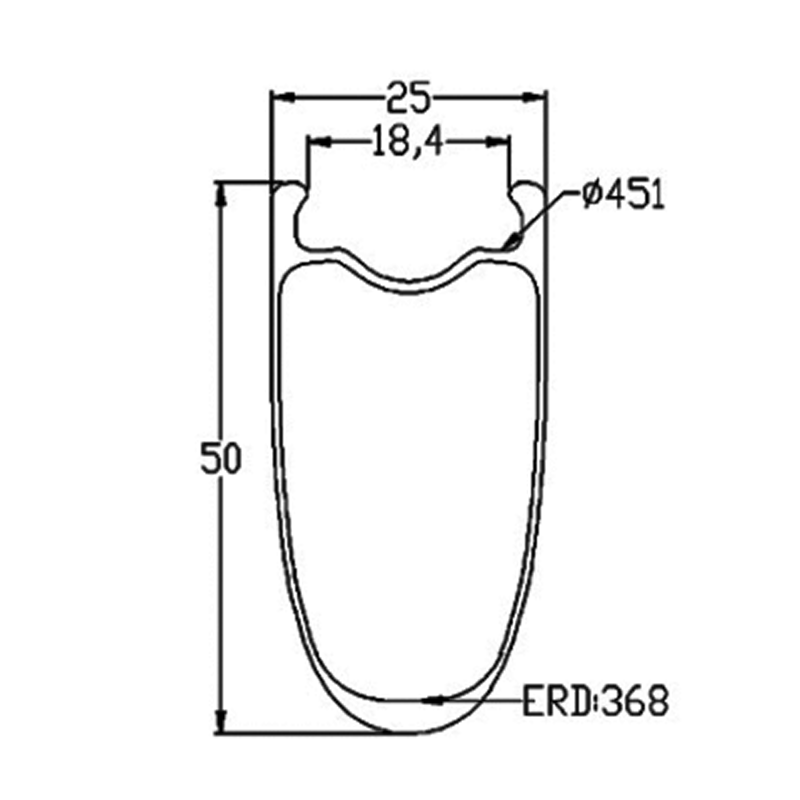

Dimension Parameter Design:

The rim height is precisely controlled at 50mm. This size not only ensures the integrity of the aerodynamic structure, reducing wind resistance interference during high-speed riding, but also avoids weight increase caused by excessive height. The 25mm outer width design, combined with optimized inner width, can form a perfectly fitting sealed structure with tubeless tires, enhancing tire side support and ensuring structural stability during cornering.

Tubeless Tire Adaptation Structure:

The inner side of the rim is equipped with a dedicated sealing groove and tire lip locking structure, enabling airtight sealing without an inner tube. The arc of the groove opening has been adjusted through multiple tests to ensure the convenience of tubeless tire installation and anti-detachment performance during use, while reducing energy loss caused by inner tube friction.

Edge and Joint Treatment:

The rim edge adopts a rounded transition design to reduce stress concentration when colliding with foreign objects during riding, reducing the risk of cracking. The spliced joints are fused through high-temperature and high-pressure curing process to ensure smooth and flat joints, which not only improves aerodynamic effects but also enhances structural integrity, avoiding local weak points affecting service life.

Application areas for the BR50X25TL-20”-451 carbon bicycle rim:

BMX Competition Scenarios:

With its 50mm height aerodynamic structure design, it can effectively reduce wind resistance during high-speed riding. Combined with the cornering stability brought by the 25mm outer width, in BMX racing, skill competitions and other competitive occasions, it can help riders improve control precision and sprint speed, meeting the high requirements for performance.

Urban Commuting Scenarios:

The lightweight (320-355g) feature reduces the riding burden. The tubeless tire adaptation structure lowers the risk of tire blowouts, reducing unexpected interruptions during commuting. At the same time, the special coating on the outer layer enhances wear resistance, which can cope with common abrasions such as gravel and sand on urban roads, making it suitable for daily short-distance or medium-to-long-distance commuting.

Outdoor Leisure Riding Scenarios:

The rounded transition design of the rim edge and the reinforced treatment of the splicing joints improve the ability to cope with complex outdoor road conditions. Whether it is suburban gravel roads, undulating roads, or scenic spot tour routes, it can ensure the stability and safety of riding, providing reliable support for leisure riding.

Personalized Modification Scenarios:

On the basis of supporting customization services, its structural design combines performance and aesthetics. It can be customized with colors and patterns according to different frame styles and personal preferences. In scenarios where BMX modification enthusiasts pursue a unique style, it can become the highlight of the whole vehicle, showing personality and taste.

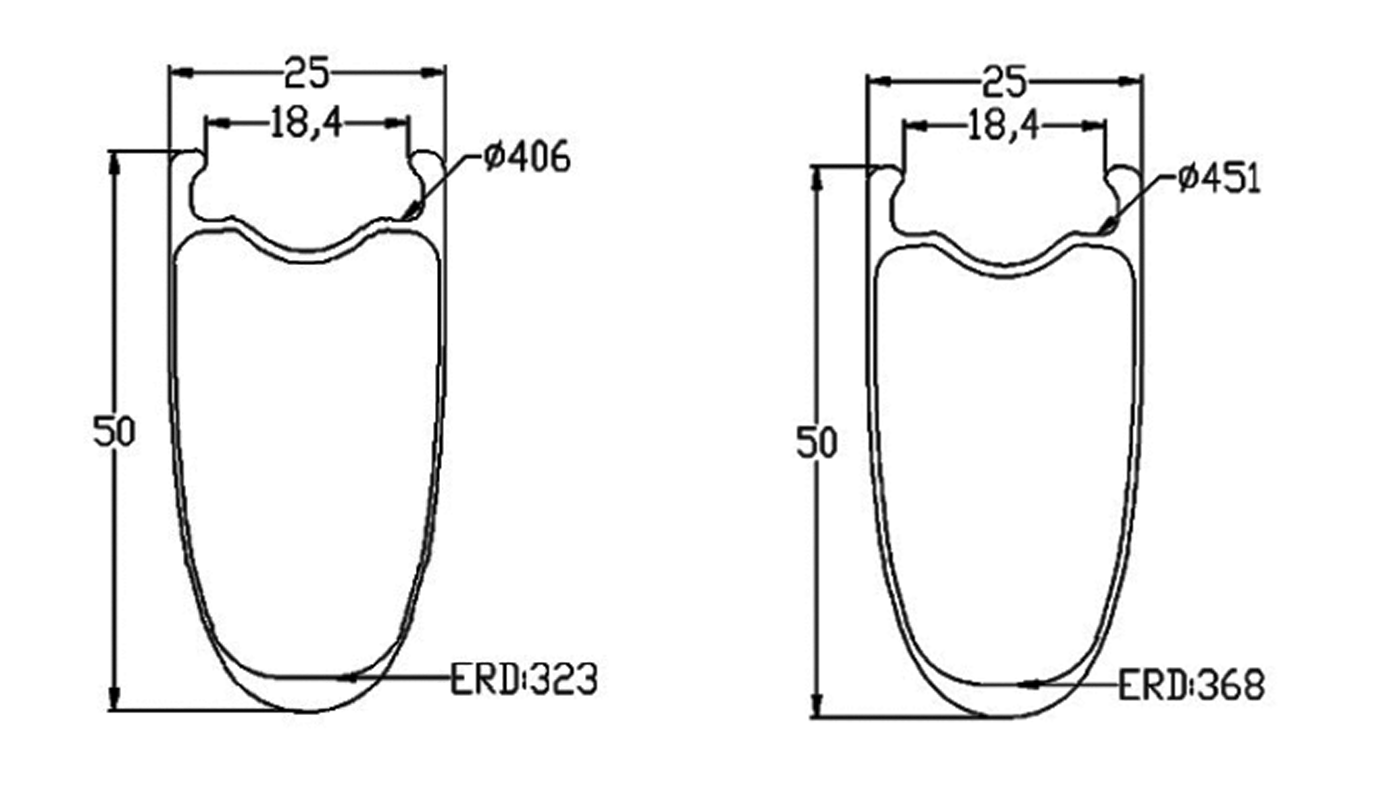

| Model | Weight (Gram) | Brake System | Inner Width | Outer Width | Depth | Available Appearance | Available Spoke Hole Counts |

| BR/BD50X25TL-20”-406-NL | 320±15g | Rim/Disc Brake | 18.4mm | 25mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| BR/BD50X25TL-20”-406-UL | 290±15g | Rim/Disc Brake | 18.4mm | 25mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| BR/BD50X25TL-20”-451-NL | 355±15g | Rim/Disc Brake | 18.4mm | 25mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| BR/BD50X25TL-20”-451-UL | 320±15g | Rim/Disc Brake | 18.4mm | 25mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

100% Customizable

Customized Weaves & Finishes:

Customized Laser Engraving Brake Track:

Customized Holes:

![]()

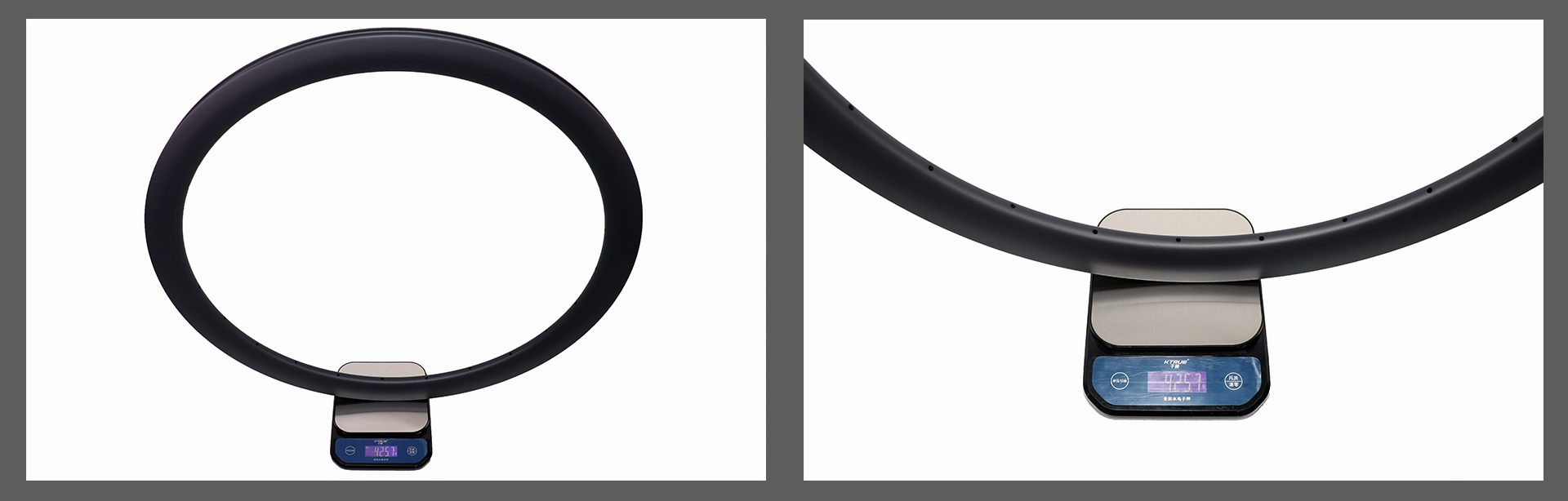

Weight Check:

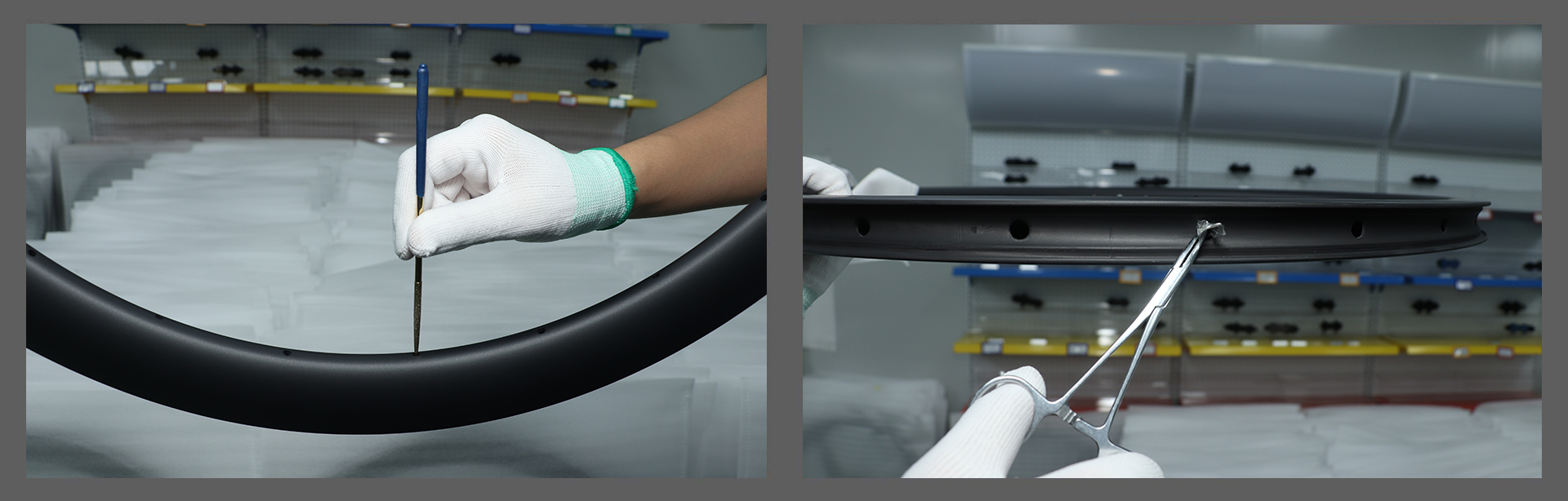

Spoke Hole Size Check:

Rim Diameters Check:

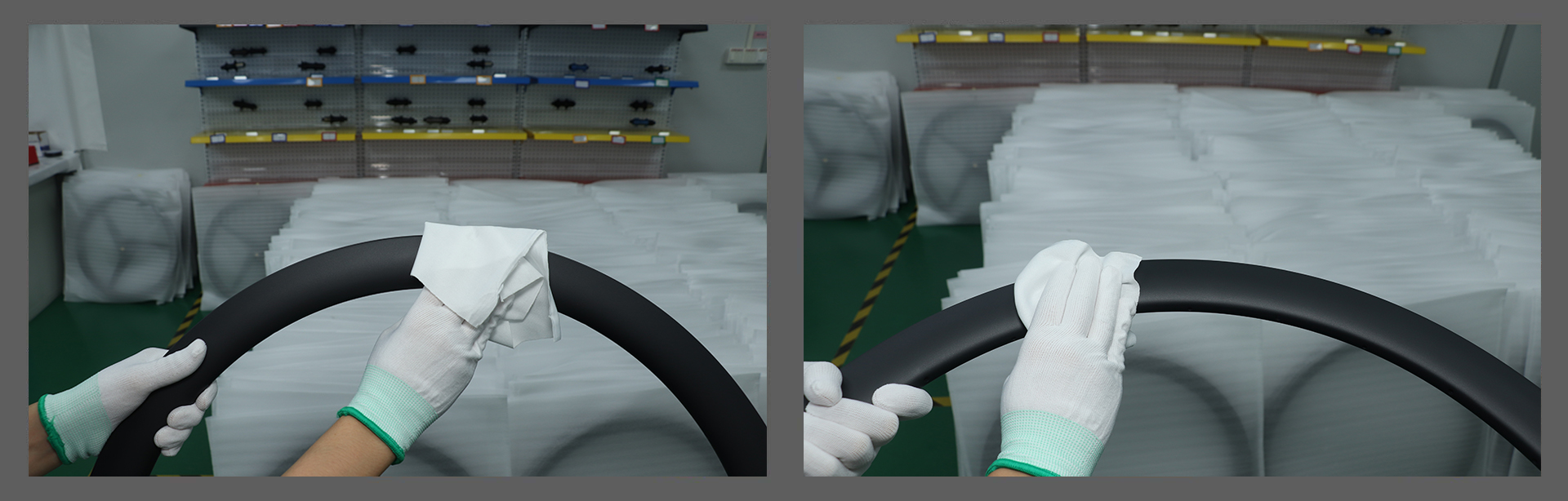

Cleaning:

Packing:

We have been in carbon bicycle production industry since the year of 2015, so 10 years history and experiences.

100 workers, 30 management, 20 Engineers, 10 Sales.

Carbon bicycle rims, carbon spokes, carbon wheels, cranks and other carbon bicycle components.

Our factory area is 2500 square meters, with 2 production lines, one wheel building line.

10.000 pcs/month for carbon rims, 100.000 pcs/month for carbon spokes, 10.000 pcs/month for other carbon bicycle components like cranks, handlebars, thru axles etc.

10-15 days for carbon rims(100-200 pcs), 7-10 days for carbon spokes, 25-30 days for carbon wheels.

It depend on the product models, quantities and and other factors, takes carbon rim for example, price generate from 80-130 USD per piece.

2 years for carbo rims and wheels, 1 year for carbon spokes.

We focus on OEM/ODM service for customers mainly on Europe and American markets.

We have signed confidential agreement with our big OEM customers, so not allow to tell, but the big brands from Europe and America.

Our factory locates in Xiamen, China.