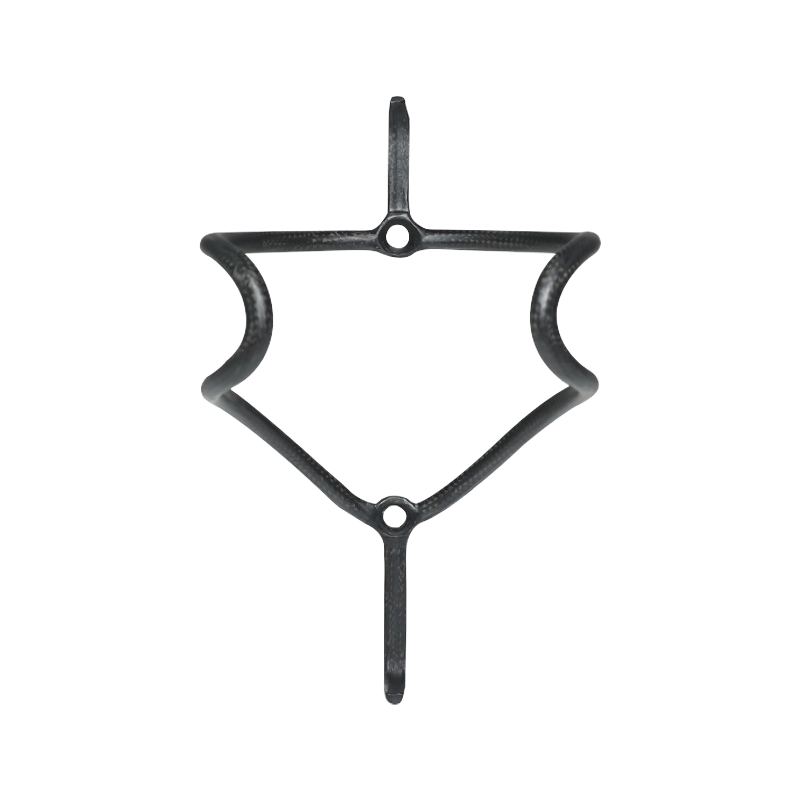

As a carbon bottle cage optimized for lightweight cycling, its core advantage lies in the synergistic weight reduction achieved through material craftsmanship and structural design. The main body utilizes Toray T700 carbon fiber unidirectional weave technology, employing a "three-layer precision layup" instead of the traditional four-layer construction. Three layers of carbon fiber are retained in the critically stressed hook area for strength, while the non-stressed areas are reduced to two layers. This achieves a balance of lightness and rigidity at an exceptionally light 10.9g. The dual upper and lower hook design overcomes the limitations of traditional single-claw hooks. The lower hook features a curved support structure, accommodating standard sports bottles (500-750ml) with a diameter of 6-8cm, saving effort when removing and placing the bottle, while preventing it from accidentally slipping.

10.9g Extremely Lightweight:

Utilizing Toray T700-grade high-modulus carbon fiber (tensile modulus 240GPa), through a unidirectional weaving and precision layup process, each cage weighs just 10.9g. This is over 15% lighter than conventional carbon fiber bottle cages (13-15g) and over 50% lighter than aluminum alloy cages (25-30g). It effectively reduces frame weight and enhances riding flexibility, making it particularly suitable for weight-sensitive riding situations such as road racing and long-distance cycling.

Upper and Lower Double Claws for Secure Clamping:

The innovative upper and lower double claws enhance friction with the bottle, creating a "lift-like" support to prevent the bottle from sinking due to bumps. In mountain gravel tests (25 km/h) and highway acceleration tests, the bottle remained stable, maintaining stable grip and preventing it from falling. Its clamping stability is 30% higher than that of a single-claw bottle cage.

Quick Installation with Two Screws:

Adapting to industry-standard 14mm-spaced bottle cage mounting holes, it requires only two screws for securement. No tools are required, and installation is completed by hand-tightening (installation time ≤ 1 minute). Once installed, it fits snugly to the frame with a clearance of ≤ 0.5mm, eliminating unwanted noise and vibration during riding. It also makes daily disassembly and cleaning easier.

High Rigidity and Deformation Resistance:

Despite its extreme weight, key areas (claws and mounting holes) are reinforced with three layers of carbon fiber, achieving a flexural strength of 1200MPa. Under a 200N tensile test (equivalent to hanging a 5kg weight), it exhibited a deformation of ≤ 0.3mm, with no permanent deformation after release. It can withstand the wear and tear of repeated bottle removal and placement during normal use, extending its service life by 20% compared to conventional carbon fiber bottle cages.

Compatible with all scenarios:

Fits standard sports bottles with a diameter of 6-8cm, ranging from 500-750ml. Whether plastic bottles or stainless steel thermoses (≤750ml), it can be stably clamped. Mounting holes are compatible with most models, including road bikes, mountain bikes, and city commuters, allowing for use without frame modification, meeting both professional cycling and everyday travel needs.

Matte Carbon Texture:

The surface is treated with a matte, transparent coating that preserves the natural texture of carbon fiber, minimizing glare in bright light while highlighting a premium look. The coating is only 0.05mm thick, adding no weight while offering a degree of scratch resistance. Minor scratches are barely noticeable, ensuring long-lasting aesthetics.

Application areas for the bottle cage:

Road Racing:

The lightweight design of 10.9g reduces frame weight and riding resistance. Combined with the stability of the upper and lower hooks, it's ideal for high-intensity events like road races and circuit races, allowing riders to focus on their pace without worrying about dropping their bottle.

Long-Distance Endurance Cycling:

Its lightweight design reduces frame strain during long rides, while its quick-install design allows for easy mid-ride adjustments. The secure grip of the upper and lower hooks ensures the bottle remains stable during challenging climbs and descents, meeting riders' frequent hydration needs and enhancing the long-distance riding experience.

Mountain Cross-Country Cycling:

The anti-slip and supportive design of the upper and lower hooks withstands the harsh vibrations of mountain gravel roads and steep slopes, preventing the bottle from slipping. The impact resistance of the carbon fiber material withstands minor impacts (such as scrapes from branches), making it suitable for light to moderate mountain cross-country cycling.

City Commuting:

The quick installation and removal feature makes it easy to remove the bottle cage after parking, preventing it from getting lost. The matte carbon finish complements most commuter bikes, meeting daily hydration needs while enhancing the overall aesthetic, achieving a perfect balance of practicality and aesthetics. Cycling Equipment Modification:

For cycling enthusiasts pursuing lightweight modifications, the 10.9g weight can be a key component in reducing frame weight. Combined with other lightweight components (such as a carbon fiber stem and lightweight saddle), it can further reduce overall weight and improve riding performance. The double-claw design also addresses the challenge of balancing lightness and stability.

The above parameters are for reference only, please consult our engineers for specific technical parameters.

We have been in carbon bicycle production industry since the year of 2015, so 10 years history and experiences.

100 workers, 30 management, 20 Engineers, 10 Sales.

Carbon bicycle rims, carbon spokes, carbon wheels, cranks and other carbon bicycle components.

Our factory area is 2500 square meters, with 2 production lines, one wheel building line.

10.000 pcs/month for carbon rims, 100.000 pcs/month for carbon spokes, 10.000 pcs/month for other carbon bicycle components like cranks, handlebars, thru axles etc.

10-15 days for carbon rims(100-200 pcs), 7-10 days for carbon spokes, 25-30 days for carbon wheels.

It depend on the product models, quantities and and other factors, takes carbon rim for example, price generate from 80-130 USD per piece.

2 years for carbo rims and wheels, 1 year for carbon spokes.

We focus on OEM/ODM service for customers mainly on Europe and American markets.

We have signed confidential agreement with our big OEM customers, so not allow to tell, but the big brands from Europe and America.

Our factory locates in Xiamen, China.