We are a factory with 10 years of expertise in carbon fiber bicycle rim production. Our BMX bicycle rims are made from carbon fiber, weighing 290-320g for a lightweight design. They feature a 50mm height for aerodynamics and a 25mm width that ensures a proper fit with tubeless tires and enhances stability. Being tubeless compatible, they help reduce puncture risks. We offer customization options for both rim and disc brakes, and we provide factory-direct supply along with personalized customization services.

Superior Material:

Our rims are made of high-quality carbon fiber, which offers exceptional advantages. It is not only incredibly lightweight (290-320g per rim) but also boasts high tensile strength and rigidity, ensuring durability and withstanding various pressures during rides. Compared to traditional materials like aluminum alloy, carbon fiber provides better vibration damping, enhancing riding comfort.

Precise Design:

The 50mm height optimizes aerodynamic performance, effectively reducing wind resistance and boosting riding speed. The 25mm outer width strengthens the fit with tubeless tires, improving stability and grip when cornering, specially designed for BMX bikes.

Strong Adaptability:

Supports tubeless tire installation, achieving good airtightness without inner tubes, thus reducing the risk of tire blowouts. It can also adapt to different road surfaces by adjusting tire pressure. Meanwhile, it can be customized for rim brakes or disc brakes to meet the braking needs of different riders.

Flexible Customization:

Offers personalized customization services, allowing customers to customize details such as the color and pattern of the rim to create an exclusive and unique rim.

Supply Advantages:

Our factory has 10 years of experience in producing carbon fiber bicycle rims, with mature and stable craftsmanship. The factory-direct sales model eliminates intermediate links, not only offering more competitive prices but also ensuring stable supply and efficient after-sales support.

Strict Quality Control:

KOBIKE do 100% tire pressure(150 PSI), flatness(<0.2mm) and roundness(<0.2mm) inspections before shipping, also offering 2 years warranty for our carbon rims.

Overall Construction:

The rim features a one-piece carbon fiber structure, formed through advanced molding processes that ensure seamless integration of all components, enhancing overall structural integrity and load-bearing capacity.

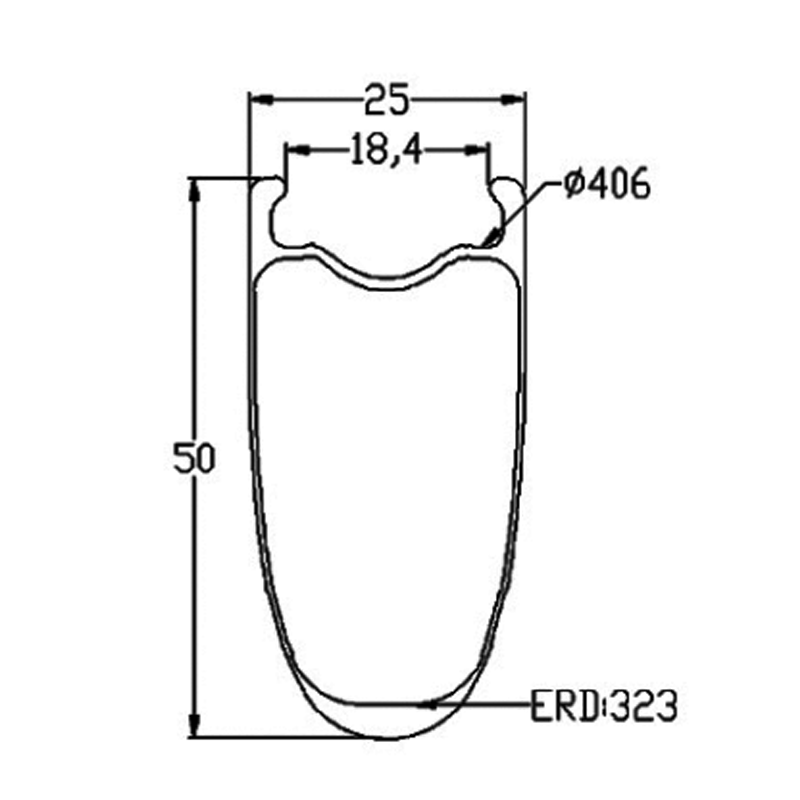

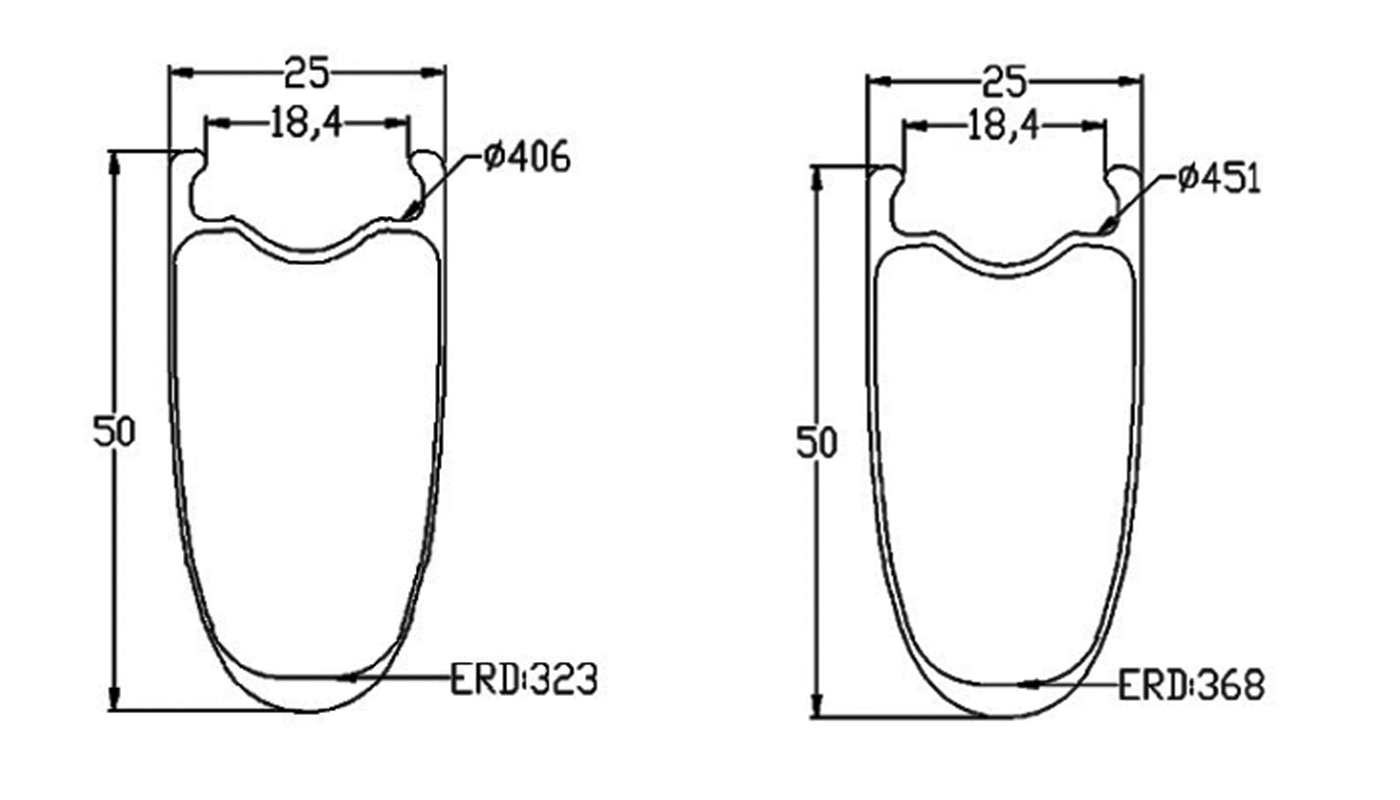

Height and Width Design:

With a 50mm height, the rim's aerodynamic profile is optimized to cut through air resistance effectively. The 25mm outer width, combined with a precisely calculated inner width, creates a stable base for tubeless tires, ensuring a secure fit and optimal contact with the road surface.

Tubeless Compatibility Structure:

The inner side of the rim is equipped with special sealing channels and bead locks. These structures work together to form an airtight seal with tubeless tires, preventing air leakage and eliminating the need for inner tubes, thus reducing weight and the risk of punctures.

Brake Compatibility Structure:

For rim brake customization, the braking surface is specially treated to ensure consistent friction and reliable braking performance. For disc brake customization, the hub interface is precisely machined to accommodate disc brake rotors, ensuring accurate alignment and smooth operation.

Reinforced Edges:

The rim edges are reinforced with additional carbon fiber layers, enhancing impact resistance and durability, which is crucial for withstanding accidental collisions and rough road conditions.

Application areas for the BD50X25TL-20”-406 carbon bicycle rim:

BMX Racing Events:

The one-piece carbon fiber structure and 50mm aerodynamic height minimize wind resistance and weight, boosting speed and acceleration—ideal for competitive racing where every second counts.

Urban Commuting:

Tubeless compatibility reduces puncture risks, while reinforced edges handle daily bumps. The lightweight design (290-320g) eases maneuvering through city traffic.

Leisure Riding on Mixed Terrains:

The 25mm width ensures stable tubeless tire performance on both smooth roads and light gravel. Brake customization (rim or disc) adapts to varying weather and terrain conditions.

Custom Build Projects:

With personalized options and precise brake compatibility, the rim integrates seamlessly into custom BMX setups, catering to riders seeking unique style and tailored performance.

| Model | Weight (Gram) | Brake System | Inner Width | Outer Width | Depth | Available Appearance | Available Spoke Hole Counts |

| BR/BD50X25TL-20”-406-NL | 320±15g | Rim/Disc Brake | 18.4mm | 25mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| BR/BD50X25TL-20”-406-UL | 290±15g | Rim/Disc Brake | 18.4mm | 25mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| BR/BD50X25TL-20”-451-NL | 355±15g | Rim/Disc Brake | 18.4mm | 25mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| BR/BD50X25TL-20”-451-UL | 320±15g | Rim/Disc Brake | 18.4mm | 25mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

100% Customizable

Customized Weaves & Finishes:

Customized Laser Engraving Brake Track:

Customized Holes:

![]()

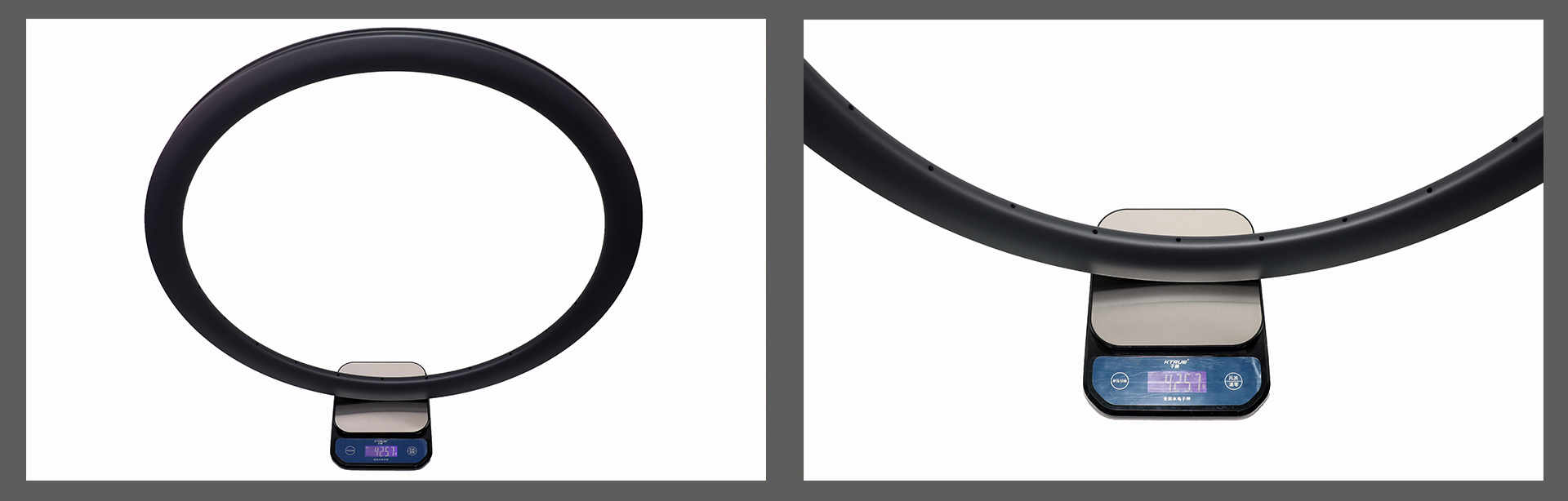

Weight Check:

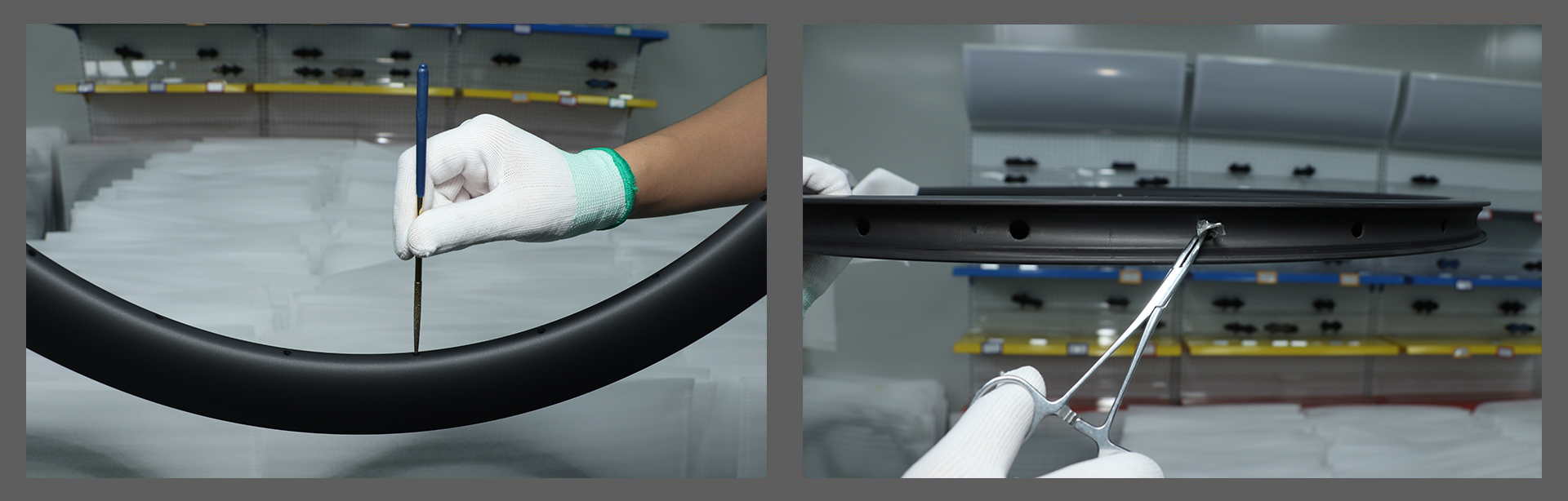

Clean burrs & residues:

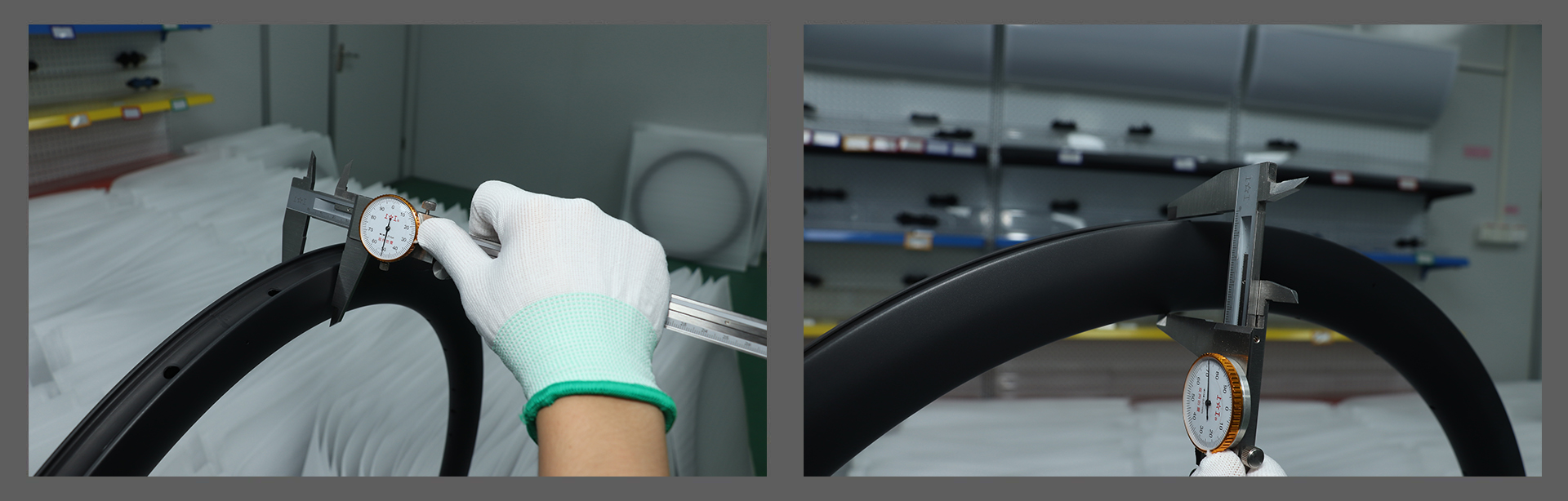

Rim Diameters Check:

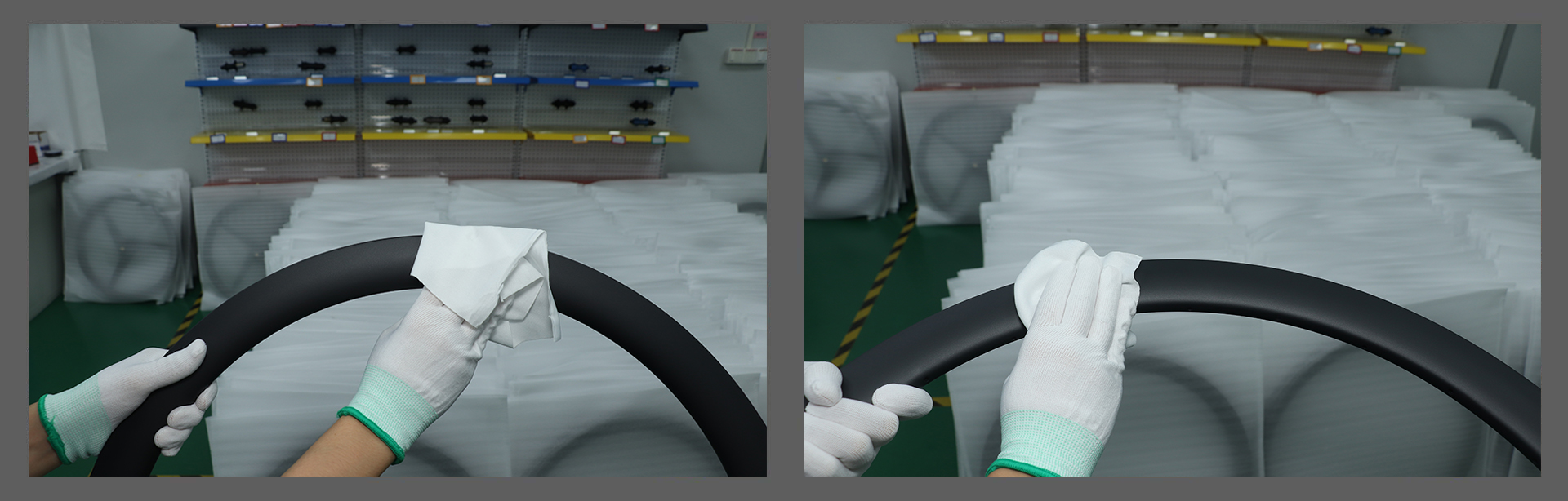

Cleaning:

Packing:

We have been in carbon bicycle production industry since the year of 2015, so 10 years history and experiences.

100 workers, 30 management, 20 Engineers, 10 Sales.

Carbon bicycle rims, carbon spokes, carbon wheels, cranks and other carbon bicycle components.

Our factory area is 2500 square meters, with 2 production lines, one wheel building line.

10.000 pcs/month for carbon rims, 100.000 pcs/month for carbon spokes, 10.000 pcs/month for other carbon bicycle components like cranks, handlebars, thru axles etc.

10-15 days for carbon rims(100-200 pcs), 7-10 days for carbon spokes, 25-30 days for carbon wheels.

It depend on the product models, quantities and and other factors, takes carbon rim for example, price generate from 80-130 USD per piece.

2 years for carbo rims and wheels, 1 year for carbon spokes.

We focus on OEM/ODM service for customers mainly on Europe and American markets.

We have signed confidential agreement with our big OEM customers, so not allow to tell, but the big brands from Europe and America.

Our factory locates in Xiamen, China.