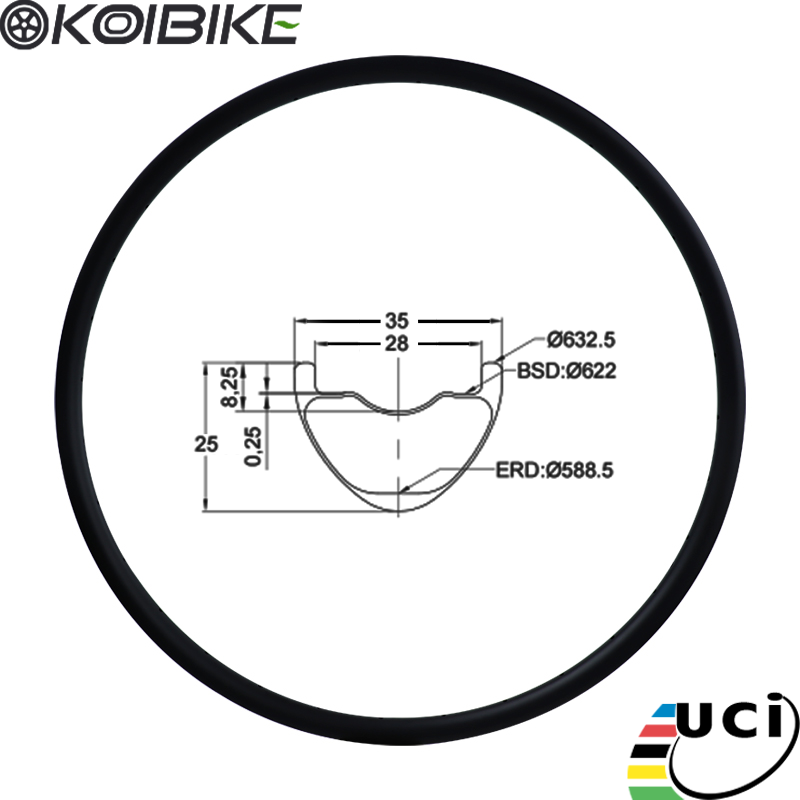

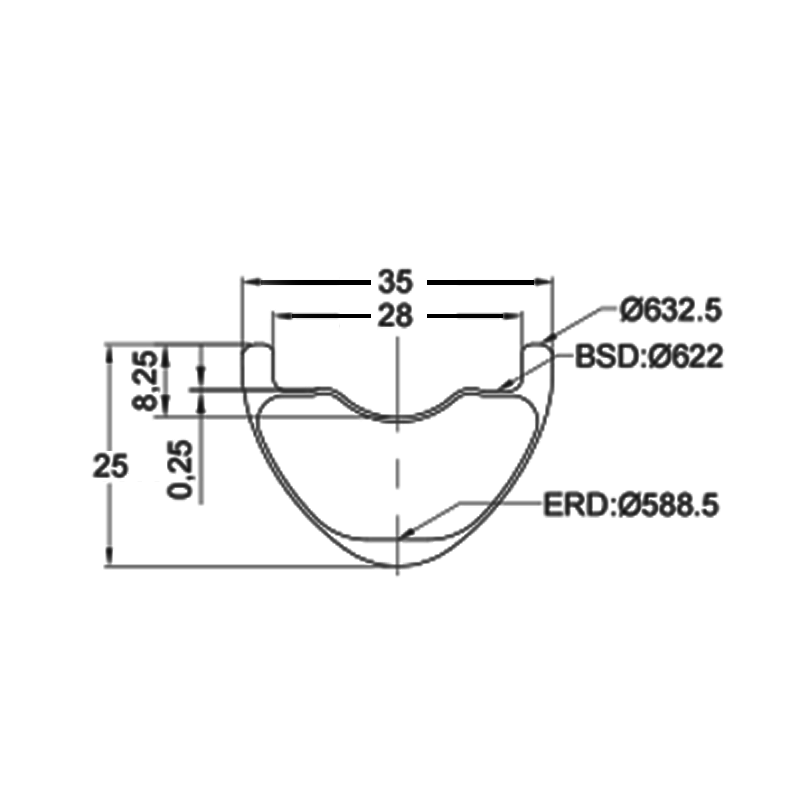

This all-terrain mountain bike rim is crafted with precision by a professional carbon fiber rim manufacturing facility. Leveraging mature carbon fiber molding techniques and strict quality control systems, the factory accurately brings to life the 25mm height and 35mm outer width hookless design — ensuring the wide rim adapts to complex terrains while the hookless structure enhances lateral support, fits tubeless tires, and reduces the risk of punctures.

The selection and processing of full carbon fiber materials are fully controlled by the factory, from raw material cutting and mold forming to stress testing. Every step adheres to high standards of strength and lightweight performance (over 30% lighter than traditional aluminum rims), guaranteeing reliable impact resistance and durability.

Additionally, the factory supports personalized customization of details such as colors, patterns, and spoke hole positions. With flexible production line responsiveness, it caters to riders' demands for exclusive equipment. Whether for off-roading, downhill, or endurance riding, this rim — rigorously refined by the factory — stands as a reliable choice that balances performance and individuality.

All-Terrain Compatible Size Design:

Adopting a golden ratio of 25mm height and 35mm outer width, the 35mm outer width can provide sufficient support for wide tires, increasing the tire's ground contact area to ensure grip on complex terrains such as gravel, mud, and tree roots. The 25mm height balances rigidity and lightweight, reducing wind resistance during high-speed riding, and is suitable for various scenarios such as off-roading, downhill, and endurance races.

Performance Enhancement of Hookless Structure:

The hookless design enhances lateral support, significantly reducing rim deformation during cornering and bumping, improving handling stability, and avoiding skidding or loss of control. It also optimizes the fit between the rim and the tire, being compatible with multiple specifications of tubeless tires. This not only eliminates the weight of inner tubes but also reduces the risk of punctures. Even if the tire is damaged, it can continue to run at low pressure, enhancing riding safety.

Lightweight Advantage of Carbon Fiber:

The full carbon fiber material is over 30% lighter than traditional aluminum alloy rims, significantly reducing the rotational inertia of the entire vehicle. This feature makes starting, accelerating, and climbing hills more effortless, reducing the rider's physical exertion. It is especially suitable for long-distance riding, maintaining efficient output continuously.

High-Strength and Durable Performance:

The carbon fiber filaments are optimally arranged in a special way, with impact resistance and structural rigidity far exceeding those of aluminum alloy. It can withstand severe impacts such as high-speed bumps and jumping landings, effectively avoiding cracks or deformation. With strong durability, it can meet the needs of high-intensity riding and provide protection for extreme challenges.

Flexible Personalized Customization:

It offers comprehensive customization from appearance to performance, including colors, patterns, spoke hole positions, and lacing methods. It meets riders' needs for exclusive equipment. Whether pursuing performance adaptation or a unique style, it can create a one-of-a-kind personal riding identity.

Strict Quality Control:

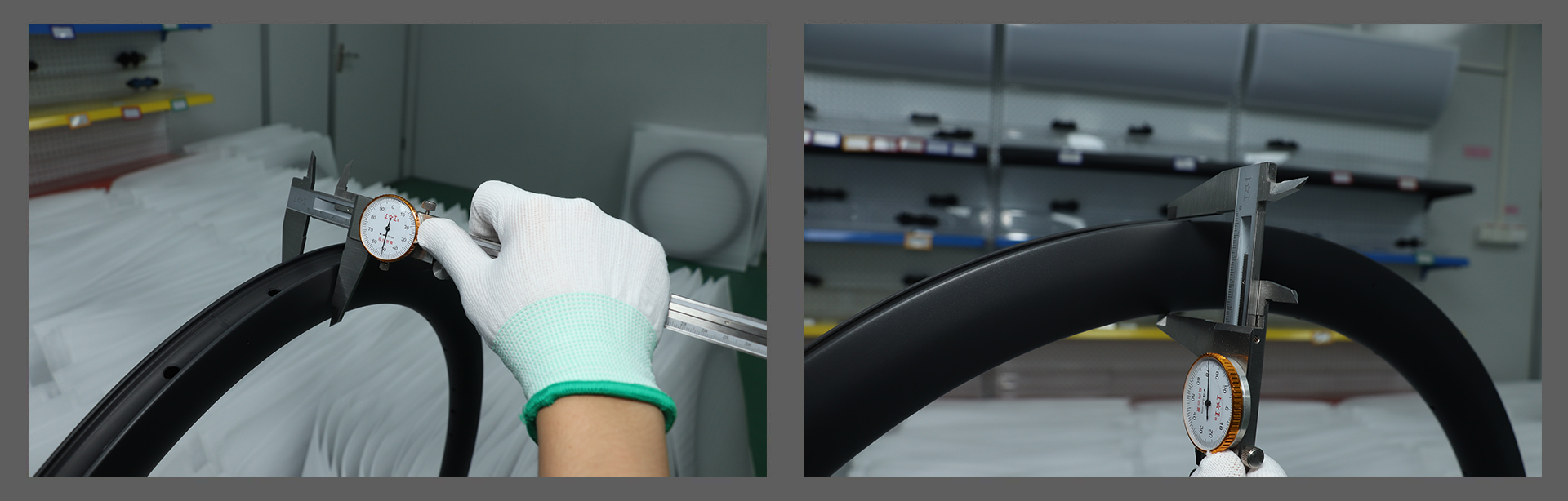

KOBIKE do 100% tire pressure(150 PSI), flatness(<0.2mm) and roundness(<0.2mm) inspections before shipping, also offering 2 years warranty for our carbon rims.

Core Rim Body:

The main structure is crafted from full carbon fiber, formed through advanced molding processes to achieve a seamless integration of 25mm height and 35mm outer width. The carbon fiber layers are strategically arranged—with high-tensile fibers oriented to enhance radial strength (resisting impact from vertical loads) and circumferential fibers boosting lateral rigidity (minimizing deformation during cornering). This layered composition ensures the rim balances lightweight properties with structural robustness.

Hookless Profile:

The hookless design features a uniform vertical wall thickness, differing from traditional hooked rims with protruding edges. This structure creates a consistent contact surface for tires, improving the seal with tubeless setups and simplifying tire mounting. The smooth, hookless edges also act as reinforcement ribs, distributing stress evenly across the rim’s circumference when navigating rough terrain, reducing the risk of localized damage that can occur with hooked designs under extreme pressure.

Spoke Hole Configuration:

Precisely drilled spoke holes are distributed evenly around the rim’s inner diameter, with countersunk edges to accommodate spoke nipples securely. The hole spacing and angle are optimized to align with common hub flange dimensions, ensuring uniform tension distribution across all spokes. This design enhances the wheel’s overall stability, preventing spoke loosening or rim warping under heavy loads.

Surface Treatment:

The outer surface undergoes a multi-step finishing process, including a protective clear coat that resists scratches and UV damage. For customized options, colored layers or graphic patterns are integrated into the carbon fiber matrix during manufacturing, ensuring the designs are durable and fade-resistant. The inner surface is smooth to minimize air resistance within the rim cavity, complementing the aerodynamic benefits of the 25mm height.

Application Areas

Application areas for the AM-M25X35HL-29ER carbon bicycle rim:

All-Terrain Exploration:

Thrives in diverse environments—rocky paths, muddy trails, deserts, meadows. Its 25mm height, 35mm width, and hookless design ensure stability, supporting adaptable tires for confident traversal of any terrain.

Mountain Riding:

Ideal for technical singletracks, steep ascents, and rugged descents. Lightweight carbon fiber enables nimble maneuvering, while high strength and hookless rigidity resist impacts from roots/rocks, ensuring precise control.

Daily Training:

Balances performance and reliability for regular sessions—climbs, cornering practice, mixed surfaces. Lightweight reduces fatigue; hookless tubeless compatibility minimizes flats, with durability for frequent use.

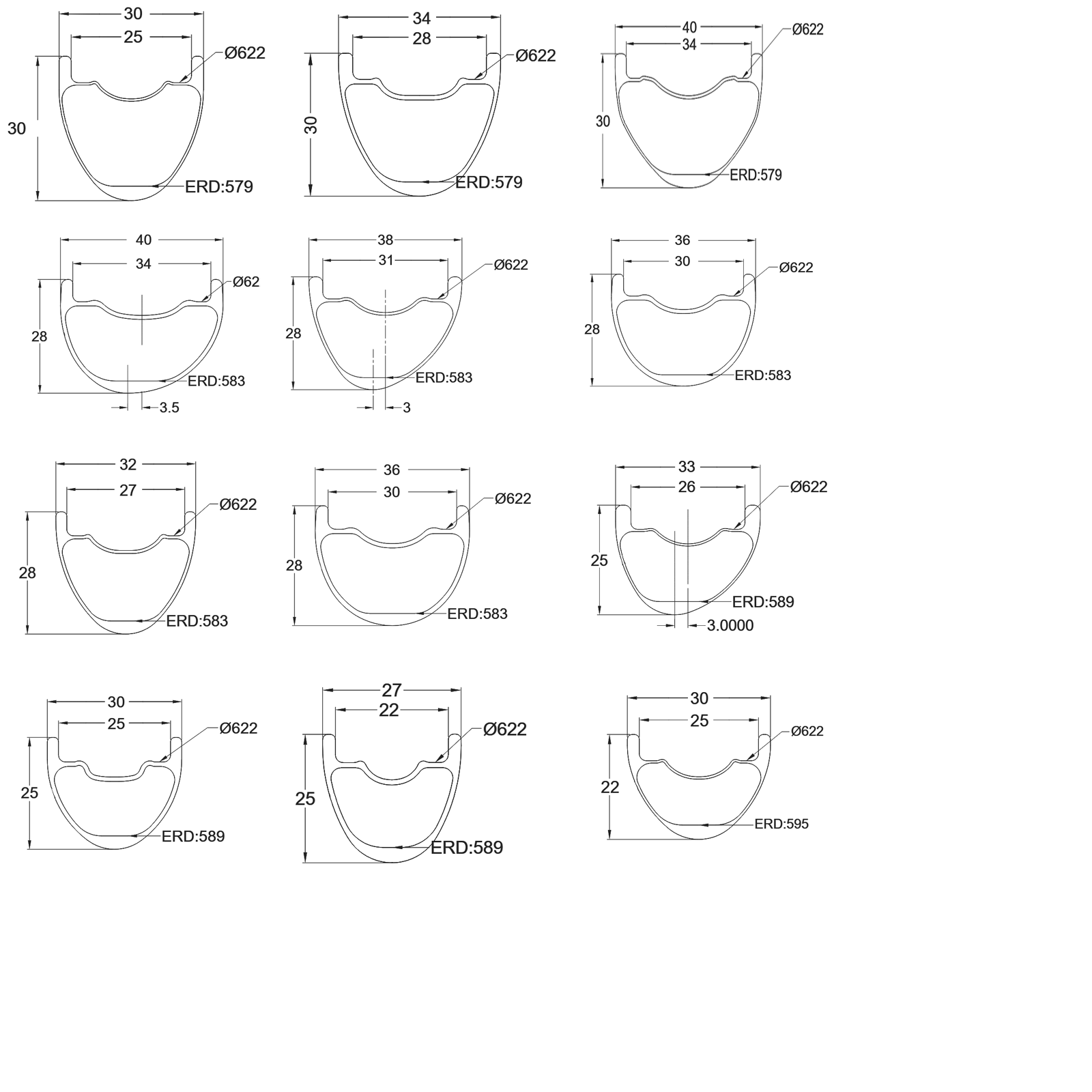

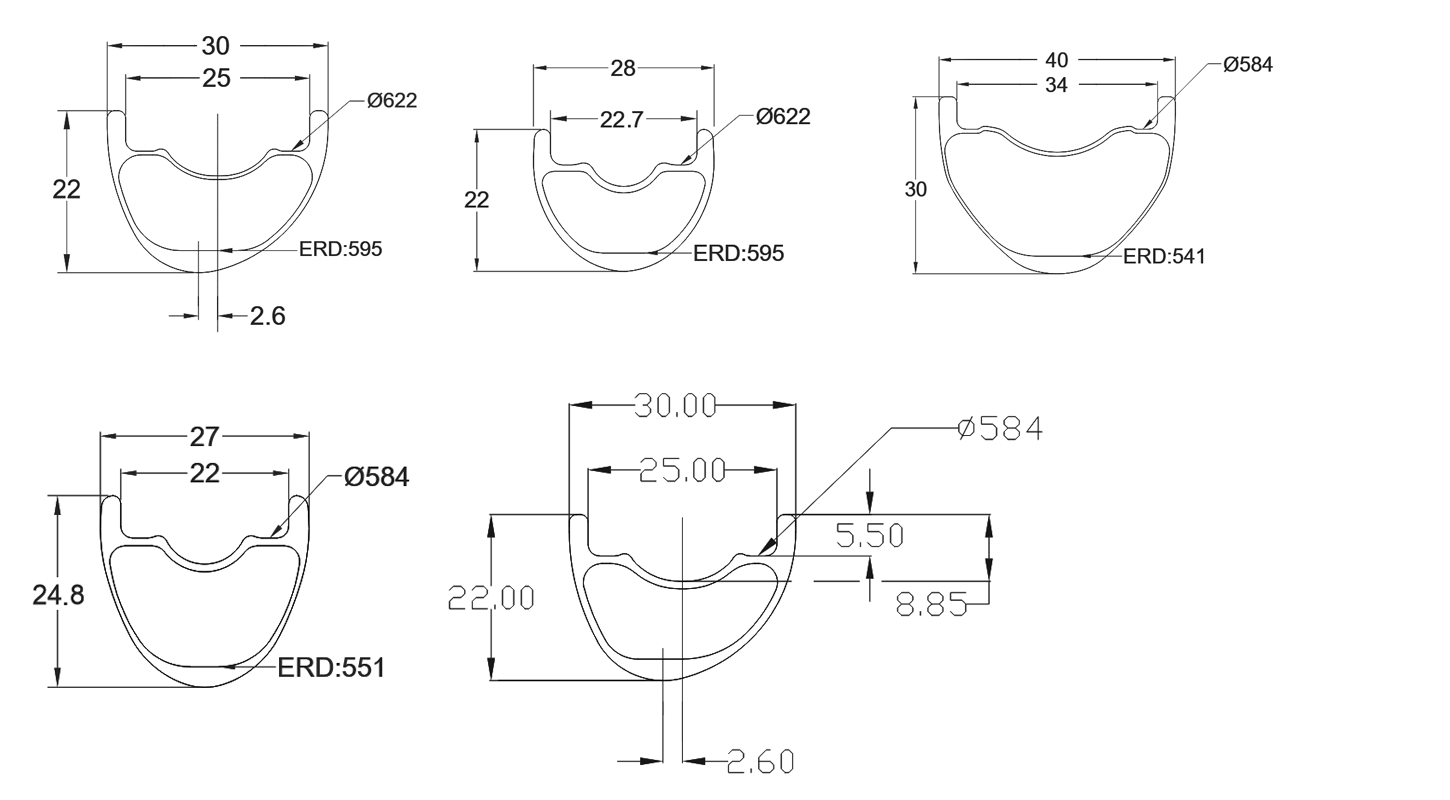

| Model | Weight (Gram) | Inner Width | Outer Width | Depth | Brake System | Available Appearance | Available Spoke Hole Counts |

| XC-M25X27HL-27.5-SL | 345±15 | 22mm | 27mm | 24.8mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-M25X27HL-27.5-UL | 265±15 | 22mm | 27mm | 24.8mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-MA22X30HL-27.5-SL | 345±15 | 25mm | 30mm | 22mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-MA22X30HL-27.5-UL | 295±15 | 25mm | 30mm | 22mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| AM-MA25X33HL-27.5-SL | 360±15 | 26mm | 33mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-MA25X33HL-27.5-UL | 320±15 | 26mm | 33mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| EN-M30X40HL-27.5-SL | 460±15 | 34mm | 40mm | 30mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| AM-M30X40HL-27.5-UL | 420±15 | 34mm | 40mm | 30mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-M22X28HL-29ER-UL | 300±15 | 22.7mm | 28mm | 22mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-MA22X30HL-29ER-NL | 360±15 | 25mm | 30mm | 22mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-MA22X30HL-29ER-SL | 310±15 | 25mm | 30mm | 22mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-MA22X30HL-29ER-UL | 255±15 | 25mm | 30mm | 22mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| XC-M22X30HL-29ER-NL | 360±15 | 25mm | 30mm | 22mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-M22X30HL-29ER-SL | 310±15 | 25mm | 30mm | 22mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-M22X30HL-29ER-UL | 255±15 | 25mm | 30mm | 22mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| XC-M25X27HL-29ER-SL | 370±15 | 22mm | 27mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-M25X27HL-29ER-UL | 285±15 | 22mm | 27mm | 25mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| XC-M20X36HL-29ER | 285±15 | 30mm | 36mm | 20mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| XC-M25X30HL-29ER-NL | 360±15 | 25mm | 30mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-M25X30HL-29ER-SL | 310±15 | 25mm | 30mm | 25mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| XC-M25X30HL-29ER-UL | 260±15 | 25mm | 30mm | 25mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| AM-MA25X33HL-29ER | 400±15 | 26mm | 33mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| TR-MA25X33HL-29ER | 380±15 | 26mm | 33mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-MA25X33HL-29ER | 340±15 | 26mm | 33mm | 25mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| AM-M25X35HL-29ER | 385±15 | 28mm | 35mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-MA25X35HL-29ER-NL | 360±15 | 30mm | 35mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-MA25X35HL-29ER-SL | 320±15 | 30mm | 35mm | 25mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| XC-MA25X35HL-29ER-UL | 280±15 | 30mm | 35mm | 25mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| XC-MA25X33HL-29ER-SL | 380±15 | 27mm | 32mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-MA25X33HL-29ER-UL | 330±15 | 27mm | 32mm | 25mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| AM-M22X30HL-29ER-SL | 435±15 | 25mm | 30mm | 22mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-M22X30HL-29ER-UL | 360±15 | 25mm | 30mm | 22mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| EN-MA28X38HL-29ER-SL | 490±15 | 31mm | 38mm | 28mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| AM-MA28X38HL-29ER-UL | 450±15 | 31mm | 38mm | 28mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| EN-MA28X40HL-29ER-SL | 490±15 | 34mm | 40mm | 28mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| AM-MA28X40HL-29ER-UL | 460±15 | 34mm | 40mm | 28mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-M30X30HL-29ER-SL | 380±15 | 25mm | 30mm | 30mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-M30X30HL-29ER-UL | 345±15 | 25mm | 30mm | 30mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| AM-M30X34HL-29ER-SL | 435±15 | 28mm | 34mm | 30mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-M30X34HL-29ER-UL | 350±15 | 28mm | 34mm | 30mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| EN-M30X40HL-29ER-SL | 480±15 | 34mm | 40mm | 30mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| AM-M30X40HL-29ER-UL | 440±15 | 34mm | 40mm | 30mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

100% Customizable

Customized Weaves & Finishes:

Customized Holes:

![]()

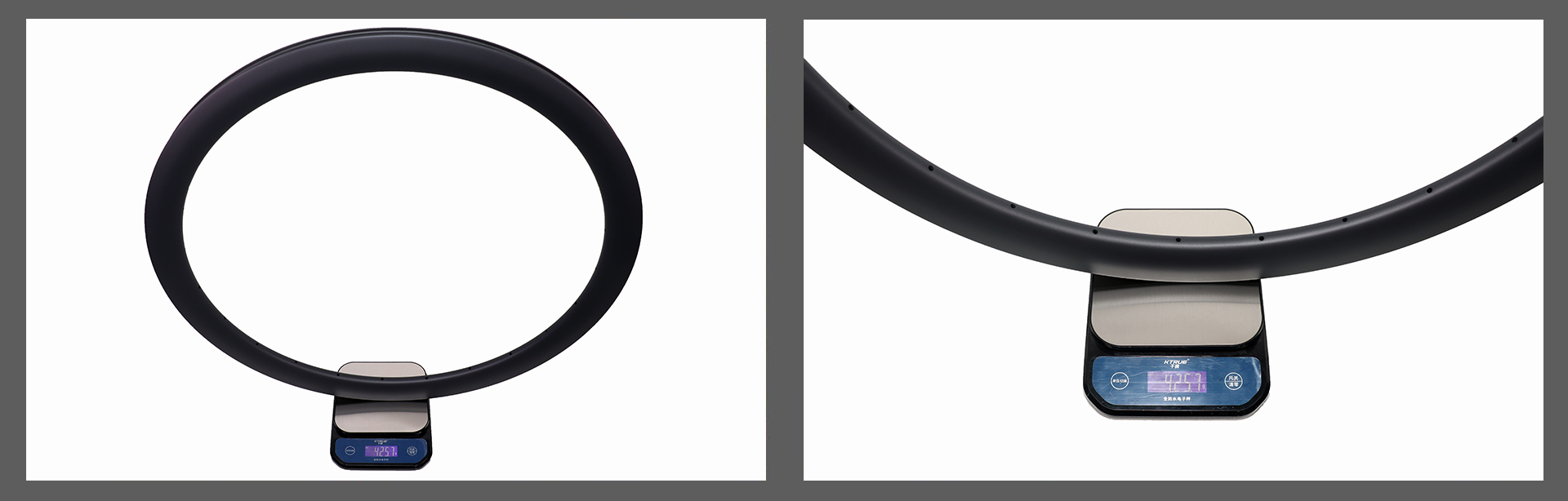

Weight Check:

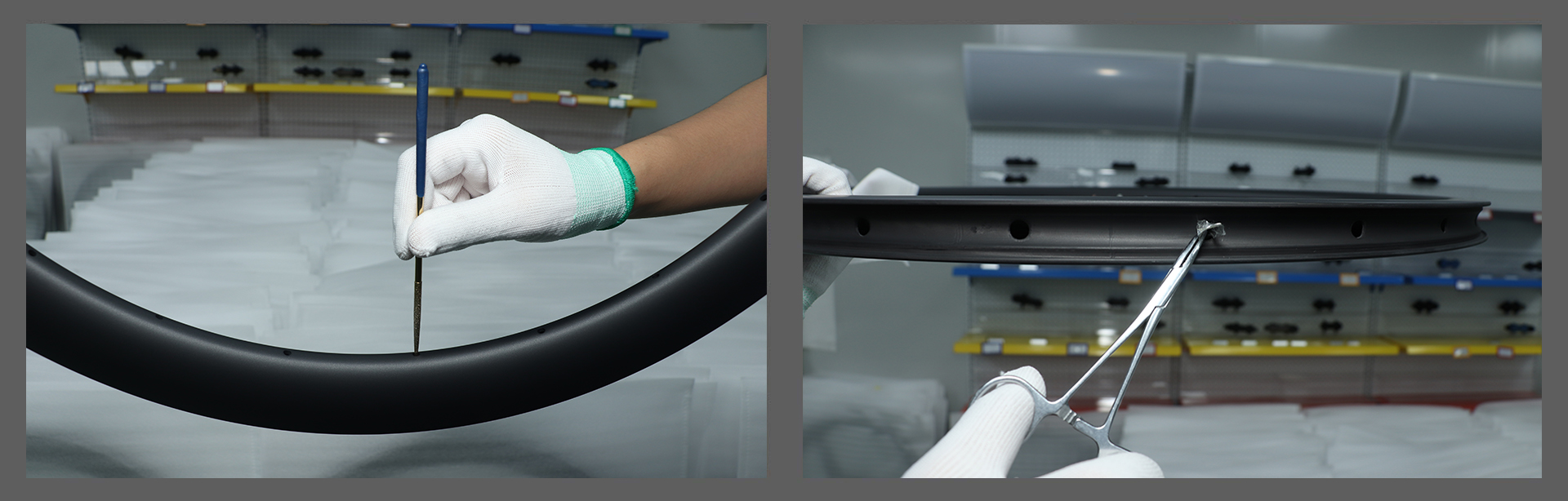

Clean burrs & residues:

Rim Diameters Check:

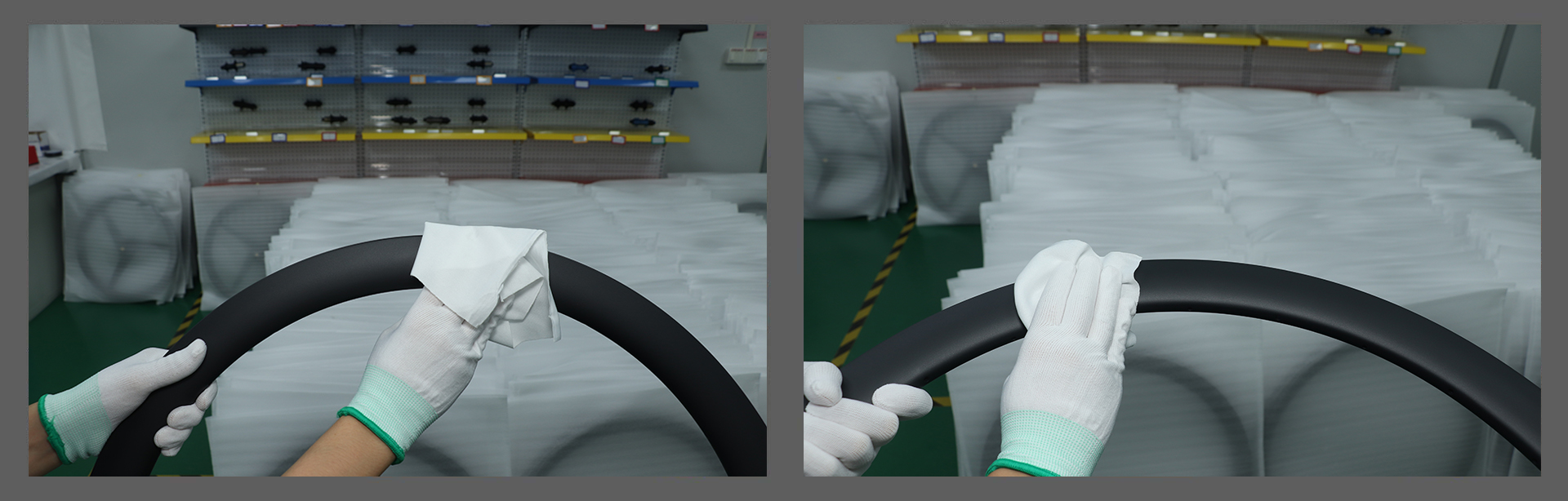

Cleaning:

Packing:

We have been in carbon bicycle production industry since the year of 2015, so 10 years history and experiences.

100 workers, 30 management, 20 Engineers, 10 Sales.

Carbon bicycle rims, carbon spokes, carbon wheels, cranks and other carbon bicycle components.

Our factory area is 2500 square meters, with 2 production lines, one wheel building line.

10.000 pcs/month for carbon rims, 100.000 pcs/month for carbon spokes, 10.000 pcs/month for other carbon bicycle components like cranks, handlebars, thru axles etc.

10-15 days for carbon rims(100-200 pcs), 7-10 days for carbon spokes, 25-30 days for carbon wheels.

It depend on the product models, quantities and and other factors, takes carbon rim for example, price generate from 80-130 USD per piece.

2 years for carbo rims and wheels, 1 year for carbon spokes.

We focus on OEM/ODM service for customers mainly on Europe and American markets.

We have signed confidential agreement with our big OEM customers, so not allow to tell, but the big brands from Europe and America.

Our factory locates in Xiamen, China.