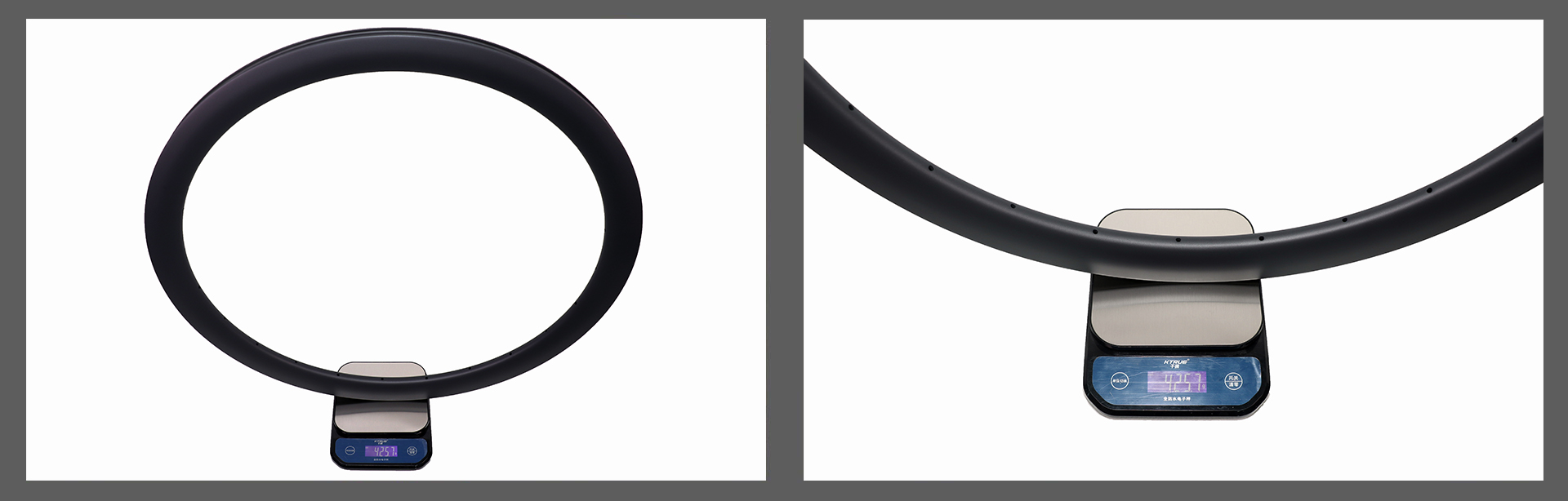

R55X26T :Designed with a 55mm competition-grade frame height and 26mm aerodynamic outer width, it's specifically designed for professional riders pursuing ultimate performance. Made from premium carbon fiber, it uses a military-grade hot-pressing process to achieve an ultra-lightweight performance of only 395g. It also improves longitudinal rigidity compared to traditional rims, and its enhanced tire lip lock design eliminates the risk of high-pressure tire debonding, reducing the chance of flats compared to traditional tubular tires.

Aerodynamics:

A 55mm rim depth reduces frontal windage and smooths airflow through the rim, providing improved crosswind stability. This provides a substantial aerodynamic advantage for speed-conscious riders without the unwieldy handling of taller rims in crosswinds. The use of modern carbon fiber materials enables lightweight designs even with a 55mm rim depth.

High Stiffness:

The use of high-strength and high-modulus carbon fiber materials (such as Toray T700 or T800) ensures exceptional structural stability while maintaining a low weight.

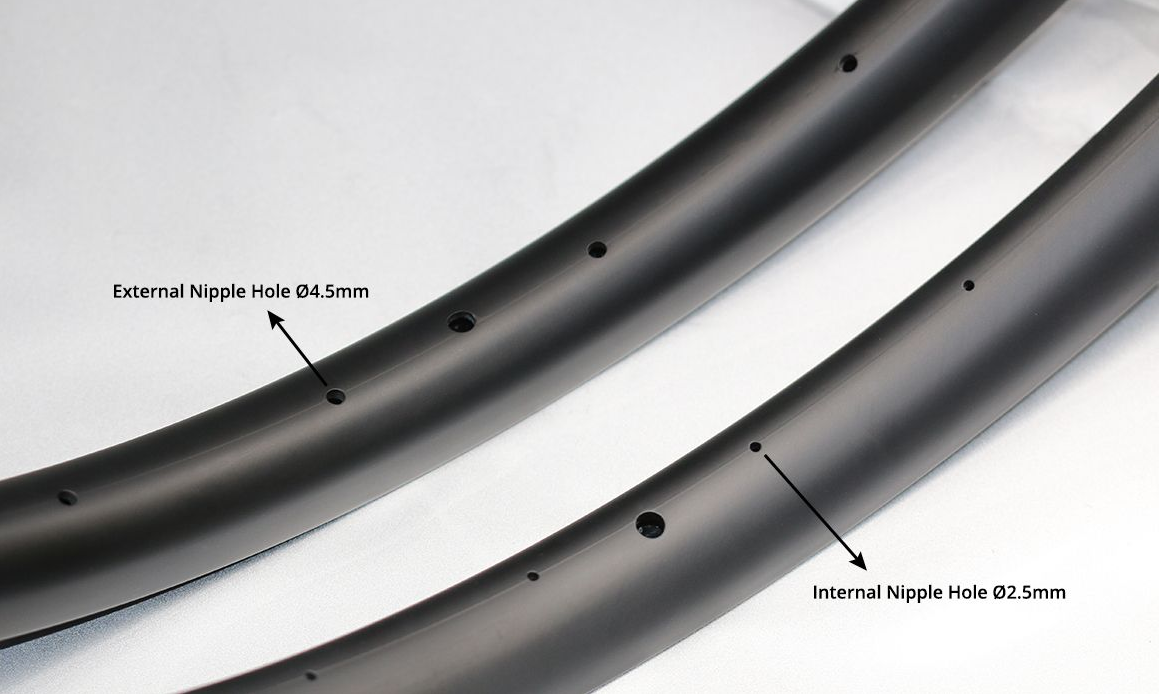

Spoke Hole Design:

Both standard symmetrical and offset spoke hole drilling methods are available. The offset design balances spoke tension on both sides, particularly on the rear drive side, contributing to overall wheel stiffness and durability. This design ensures more efficient energy transfer from the pedals to the ground during high power outputs.

Spoke Configuration and Lacing:

High-performance spokes, such as Sapim CX-Ray, are typically used, with a specific lacing pattern (e.g., radial lacing on the front wheel and 2-cross radial lacing on the non-drive side of the rear wheel). This configuration not only enhances the lateral stiffness of the rim but also improves the responsiveness and efficiency of the overall structure.

High-Temperature Braking Performance:

Carbon fiber itself possesses excellent heat resistance. KOIBIKE's in-house developed Obsidian brake rims are rated for temperatures up to 200°C. To enhance heat resistance, especially against the heat generated during braking, KOIBIKE's carbon fiber rims typically utilize a special heat-resistant resin and surface treatment on the braking surface.

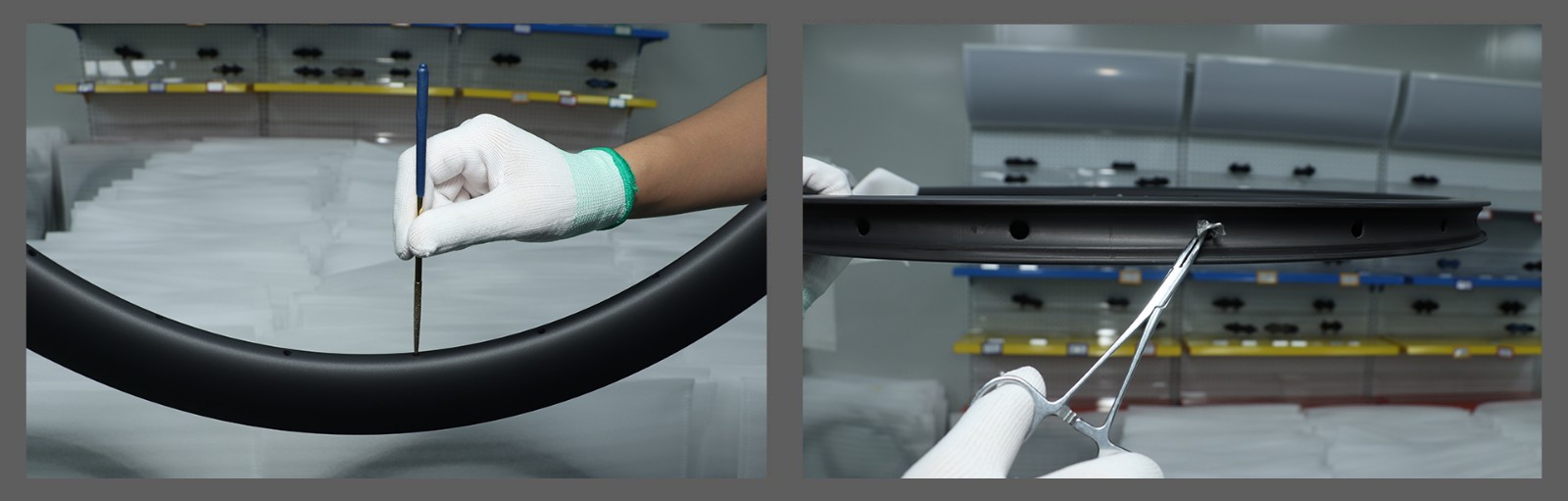

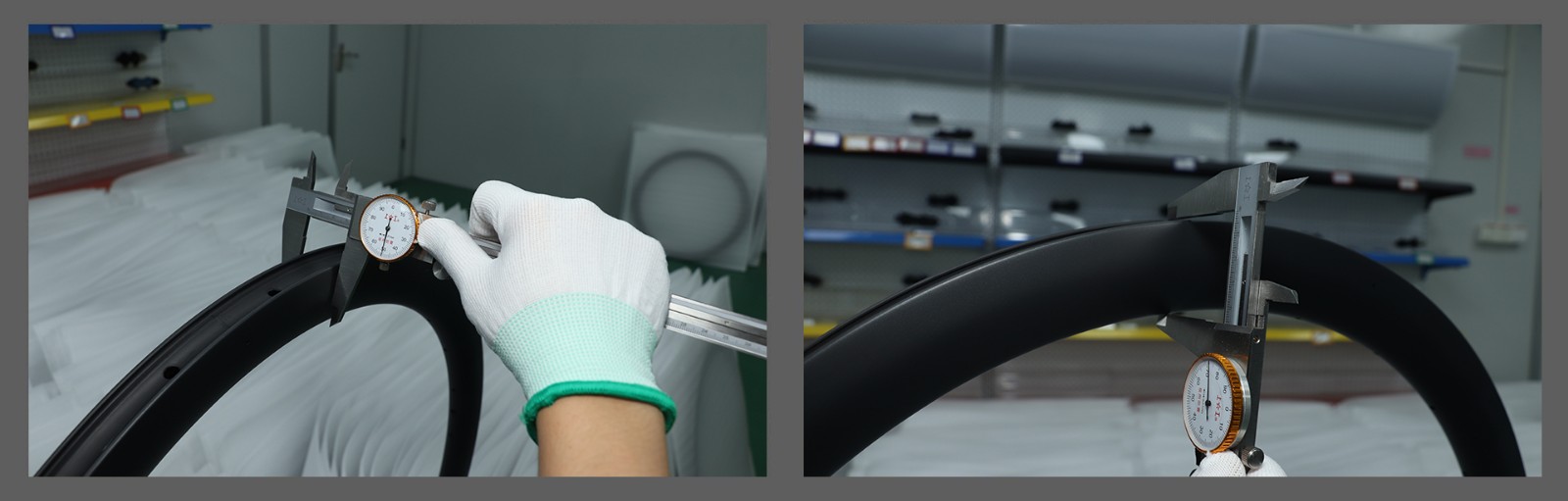

Strict Quality Control:

KOBIKE do 100% tire pressure(150 PSI), flatness(<0.2mm) and roundness(<0.2mm) inspections before shipping, also offering 2 years warranty for our carbon rims.

Tubular rim tires

Supporting a range of tire widths (e.g., 23C to 42C), tubular tires are fully sealed and airtight, eliminating the need for a tube. This means they can be run at lower pressures, improving comfort and traction while reducing rolling resistance.

Rim Sidewalls

To facilitate installation and removal of tubular tires, the rim's sidewalls are typically smooth and slightly concave. This helps the tire adhere more easily to the rim and ensures good adhesion. The rim's sidewalls may have a matte or glossy finish, which not only affects aesthetics but also durability and ease of maintenance. In some cases, special coatings are applied to increase wear resistance or improve braking performance, ensuring high performance and a long lifespan.

Braking Interface:

For non-disc brake wheels, the rim's sidewalls also require a good braking interface. This often involves special resins or coatings to ensure stable braking performance even in high-temperature conditions.

Road Racing:

In professional competitions, especially time trials and individual pursuit events, tubular rims are highly favored for their light weight, high stiffness, and excellent aerodynamics. They offer low rolling resistance and improved speed retention, making them ideal for events where speed and efficiency are paramount.

Endurance & Long-Distance Touring:

While tubular rims have traditionally been used primarily for racing, technological advancements have led to their increasing adoption in long-distance cycling and endurance events. Wider tire widths (e.g., 23C to 42C) allow riders to choose a more comfortable tire setup to combat fatigue from extended rides and improve adaptability to varying road conditions.

Climbing:

For courses with frequent ups and downs, the lightweight design of tubular rims helps reduce overall weight, making climbing easier. Furthermore, their superior acceleration helps riders exit corners and recover faster.

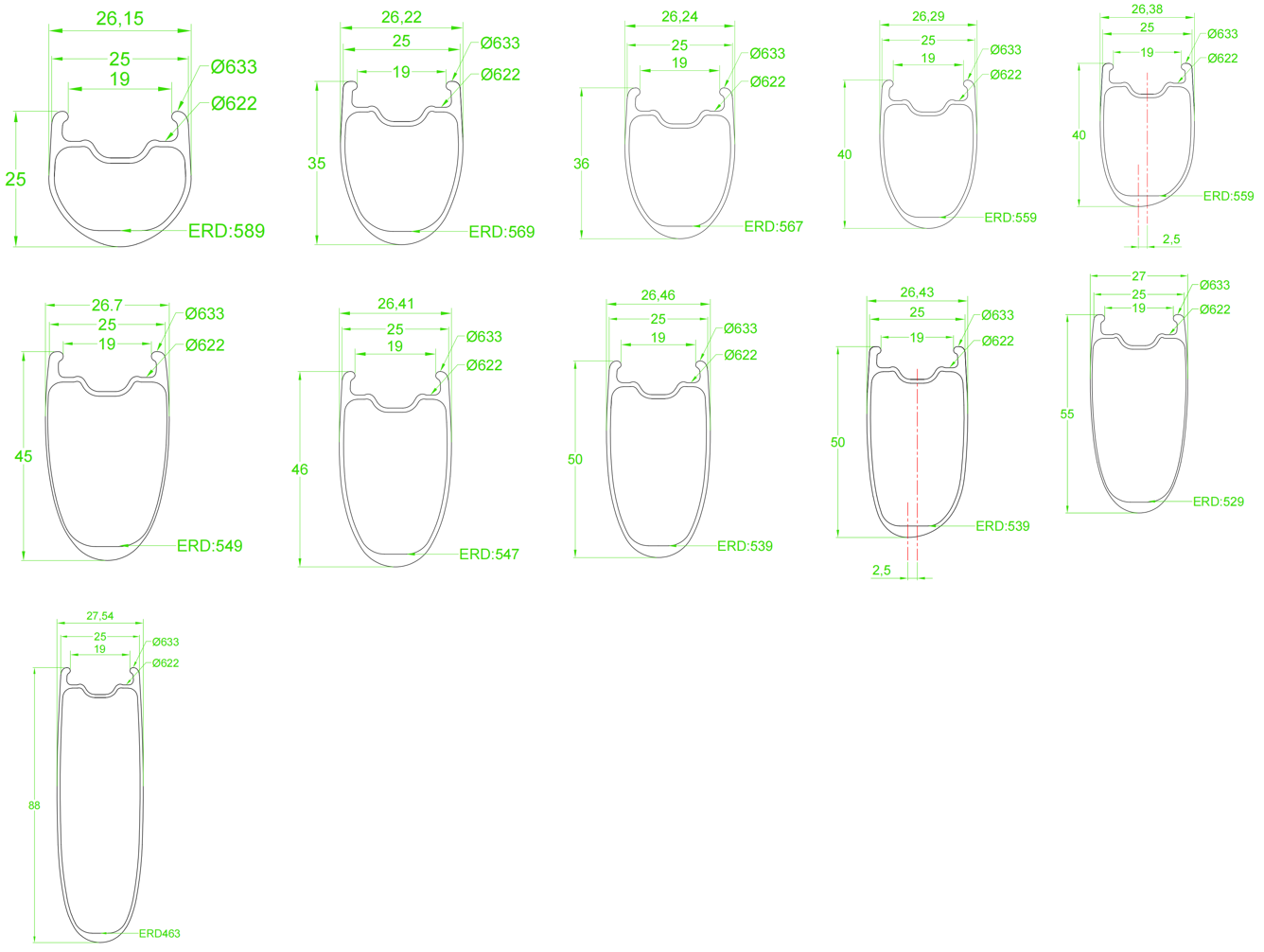

| Model | Weight (Gram) | Brake System | Inner Width | Outer Width | Depth | Available Appearance | Available Spoke Hole Counts |

R25X26TL-NL | 390±15g | Rim/Disc Brake | 19mm | 26mm | 25mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

R25X26TL-UL | 365/330±15g | Rim/Disc Brake | 19mm | 26mm | 25mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

D25X26TL-SL | 360±15g | Disc Brake | 19mm | 26mm | 25mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

R35X26TL-NL | 435±15g | Rim/Disc Brake | 19mm | 26mm | 35mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

R35X26TL-UL | 410/350±15g | Rim/Disc Brake | 19mm | 26mm | 35mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| D35X26TL-SL | 400±15g | Disc Brake | 19mm | 26mm | 35mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R36X26TL-NL | 435/420±15g | Rim/Disc Brake | 19mm | 26mm | 36mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R36X26TL-UL | 410/350±15g | Rim/Disc Brake | 19mm | 26mm | 36mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| D36X26TL-SL | 400±15g | Disc Brake | 19mm | 26mm | 36mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R40X26TL-NL | 455/440±15g | Rim/Disc Brake | 19mm | 26mm | 40mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R40X26TL-UL | 435/375±15g | Rim/Disc Brake | 19mm | 26mm | 40mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| D40X26TL-SL | 420±15g | Disc Brake | 19mm | 26mm | 40mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| RA40X26TL-NL | 455/440±15g | Rim/Disc Brake | 19mm | 26mm | 40mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| RA40X26TL-UL | 435/375±15g | Rim/Disc Brake | 19mm | 26mm | 40mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| DA40X26TL-SL | 420±15g | Disc Brake | 19mm | 26mm | 40mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R45X26TL-NL | 475/460±15g | Rim/Disc Brake | 19mm | 26mm | 45mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R45X26TL-UL | 455/390±15g | Rim/Disc Brake | 19mm | 26mm | 45mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| D45X26TL-SL | 440±15g | Disc Brake | 19mm | 26mm | 45mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R46X26TL-NL | 475/460±15g | Rim/Disc Brake | 19mm | 26mm | 46mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R46X26TL-UL | 455/390±15g | Rim/Disc Brake | 19mm | 26mm | 46mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| D46X26TL-SL | 440±15g | Disc Brake | 19mm | 26mm | 46mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R50X26TL-NL | 495/480±15g | Rim/Disc Brake | 19mm | 26mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R50X26TL-UL | 475/420±15g | Rim/Disc Brake | 19mm | 26mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| D50X26TL-SL | 460±15g | Disc Brake | 19mm | 26mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| RA50X26TL-NL | 495/480±15g | Rim/Disc Brake | 19mm | 26mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| RA50X26TL-UL | 475/420±15g | Rim/Disc Brake | 19mm | 26mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| DA50X26TL-SL | 460±15g | Disc Brake | 19mm | 26mm | 50mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R55X26TL-NL | 525/500±15g | Rim/Disc Brake | 19mm | 26mm | 55mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R55X26TL-UL | 405/440±15g | Rim/Disc Brake | 19mm | 26mm | 55mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| D55X26TL-SL | 480±15g | Disc Brake | 19mm | 26mm | 55mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R55X26T-UL | 395±15g | Rim/Disc Brake | - | 26mm | 55mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R88X27TL-NL | 660/640±15g | Rim/Disc Brake | 19mm | 26mm | 88mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| R88X27TL-UL | 640/620±15g | Rim/Disc Brake | 19mm | 26mm | 88mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

100% Customizable

Customized Weaves & Finishes:

Customized Laser Engraving Brake Track:

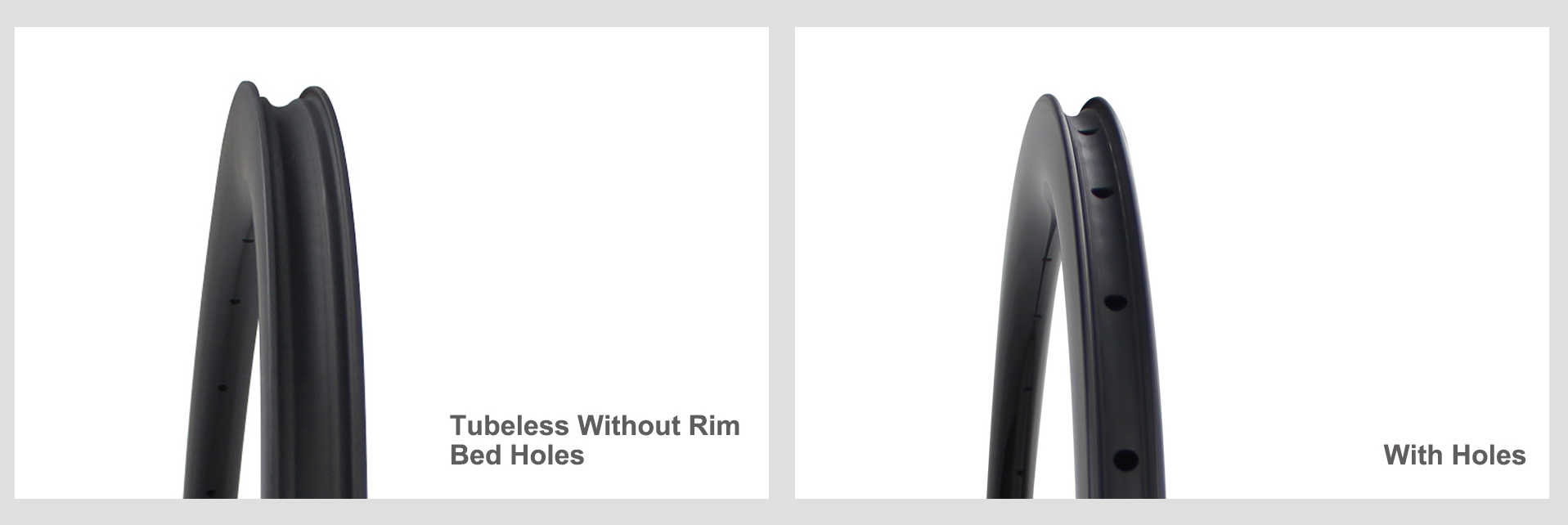

Customized Holes:

![]()

Weight Check:

Clean burrs & residues

Rim Diameters Check:

Cleaning & Packing

We have been in carbon bicycle production industry since the year of 2015, so 10 years history and experiences.

100 workers, 30 management, 20 Engineers, 10 Sales.

Carbon bicycle rims, carbon spokes, carbon wheels, cranks and other carbon bicycle components.

Our factory area is 2500 square meters, with 2 production lines, one wheel building line.

10.000 pcs/month for carbon rims, 100.000 pcs/month for carbon spokes, 10.000 pcs/month for other carbon bicycle components like cranks, handlebars, thru axles etc.

10-15 days for carbon rims(100-200 pcs), 7-10 days for carbon spokes, 25-30 days for carbon wheels.

It depend on the product models, quantities and and other factors, takes carbon rim for example, price generate from 80-130 USD per piece.

2 years for carbo rims and wheels, 1 year for carbon spokes.

We focus on OEM/ODM service for customers mainly on Europe and American markets.

We have signed confidential agreement with our big OEM customers, so not allow to tell, but the big brands from Europe and America.

Our factory locates in Xiamen, China.