KOIBIKE leverages the technological expertise of its own factory to create this rim. The AM-MA28X40HL-29ER-UL all-mountain rims are a professional solution for all-mountain and enduro riding. Our factory's sophisticated carbon fiber processing system supports mass customization and fast delivery for B2B customers, with complete control over the entire process, from material selection to finished product inspection. The 28mm-deep rim body is constructed from Toray T800-grade carbon fiber, molded using a gradient lamination process. At a weight of 460±15 grams, it boasts a 25% improvement in impact strength compared to standard all-mountain rims. The 40mm outer width provides rigid support for ultra-wide tires, while the 3.5mm offset hole diameter ensures more even distribution of centrifugal force during wheel rotation. Both hookless and hooked rims are available to meet diverse tire mounting requirements and riding styles. The all-mountain model offers enhanced torsional resistance for extreme terrain, while the enduro model optimizes rolling efficiency for long-distance riding, providing a highly adaptable core component for OEMs and dealers.

Wide Terrain Control:

40mm Outer Width Compatibility Ultra-wide 2.25-3.1-inch tires offer an 18% increase in contact patch compared to 38mm rims, distributing pressure and preventing tire sinking on extreme terrain like soft snow slopes and gravel flats. With a tire pressure adjustment range of 19-29, grip mode can be precisely adjusted based on road surface hardness, ensuring flawless all-terrain versatility.

Lightweight and Strong Balance:

Thanks to its carbon fiber one-piece molding process and hollow design, the ultra-lightweight 460±15g rim is 35% lighter than a comparable aluminum alloy rim. Furthermore, the T800 carbon fiber boasts a tensile strength of 5.8GPa, maintaining deflection within 0.3mm even when subjected to a 120kg rider and severe impact, ensuring both flexibility and durability.

Offset Aperture Technology:

The 3.5mm offset aperture minimizes spoke tension distribution error to less than 5% by calculating the moment arm relationship between the rim and hub, reducing radial runout to 0.1mm during rotation, significantly less than conventional designs. 40% energy loss, delivering more direct power transfer and zero lag during continuous climbing and high-speed descents.

Dual Edge Technology Showdown:

The hookless straight edge features a hookless design that forms a surface-to-surface seal with the tubeless tire bead, improving airtightness by 30%, reducing installation time by 50%, and reducing stress concentration on the edge for improved impact resistance. The hook edge is compatible with traditional inner tubes and mechanically locks the tire for enhanced tire retention, making it ideal for racing with high tire pressures. These two options cover all riding needs.

Diverse Appearances and Protection:

The UD/Marble/12K/12K Twill finish utilizes a nano-ceramic coating with a surface hardness of HRC50. This reduces scratch depth on rocks to within 0.02mm, increasing wear resistance by 60% compared to conventional coatings, ensuring a pristine finish even after long-term outdoor use.

Strict Quality Control:

KOBIKE do 100% tire pressure(150 PSI), flatness(<0.2mm) and roundness(<0.2mm) inspections before shipping, also offering 2 years warranty for our carbon rims.

Hookless/Hooked Cross-Sectional Analysis:

The hookless has a smooth, rounded cross-section, creating a 15° angle between the sidewall and the rim after installation. The rim features a cambered angle to distribute lateral forces; the hook edge features a 2.5mm raised claw that mechanically engages the tire. Both structures have passed 1,000 cycles of fatigue testing to ensure structural stability under extreme conditions.

Rim Mechanical Matrix:

The 28mm-tall rim utilizes a "honeycomb" carbon fiber weave. The longitudinal fibers enhance tensile strength, while the circumferential fibers increase torsional strength. With a 40mm external width for lateral support, the rim achieves a roll stiffness of 800N/mm during cornering, a 30% improvement over narrower rims of the same height.

Bead Seal:

Three stepped grooves on the inner side create a labyrinth-like seal with the tubeless tire when combined with the hookless straight edge. Even at -15°C, tire pressure decay is kept to 0.5psi/hour, making it more stable than a traditional single-groove design.

Offset Hole Layout:

The 3.5mm offset, optimized through CAD simulation, maintains a constant spoke-rim tangent angle. 22°, the optimal mechanical angle, evenly distributes the centrifugal force during rotation to the hub bearings, extending service life by over 30%.

Application areas for the AM-MA28X40HL-29ER-UL carbon bicycle rim:

All-Mountain Extreme Challenge:

The All-Mountain model exhibited no cracks in a 3-meter drop test, making it suitable for demanding scenarios like rock ledge descents and rocky slopes, providing reliable support for hardcore riders.

Enduro Long-Distance Expedition: The Enduro model offers 8% less rolling resistance than standard rims over a 6-hour continuous ride, making it ideal for mountain marathons under 200 kilometers, saving riders energy.

Snow and Mud Crossing:

The 40mm outer width paired with a 3.1-inch puncture-resistant tire provides 40% greater flotation in 15cm deep snow and 25% greater mud shedding, making it an ideal choice for winter adventures and rainy season off-roading.

Team Customization:

Custom paint jobs in team colors are supported, including 3.5mm The offset bore diameter accommodates mainstream hub specifications, providing professional teams with a personalized, high-performance wheel solution.

Advanced Player Upgrade:

The upgraded carbon rim reduces overall weight by approximately 1.2kg and improves handling responsiveness by 15%, making it ideal for advanced riders seeking breakthrough performance.

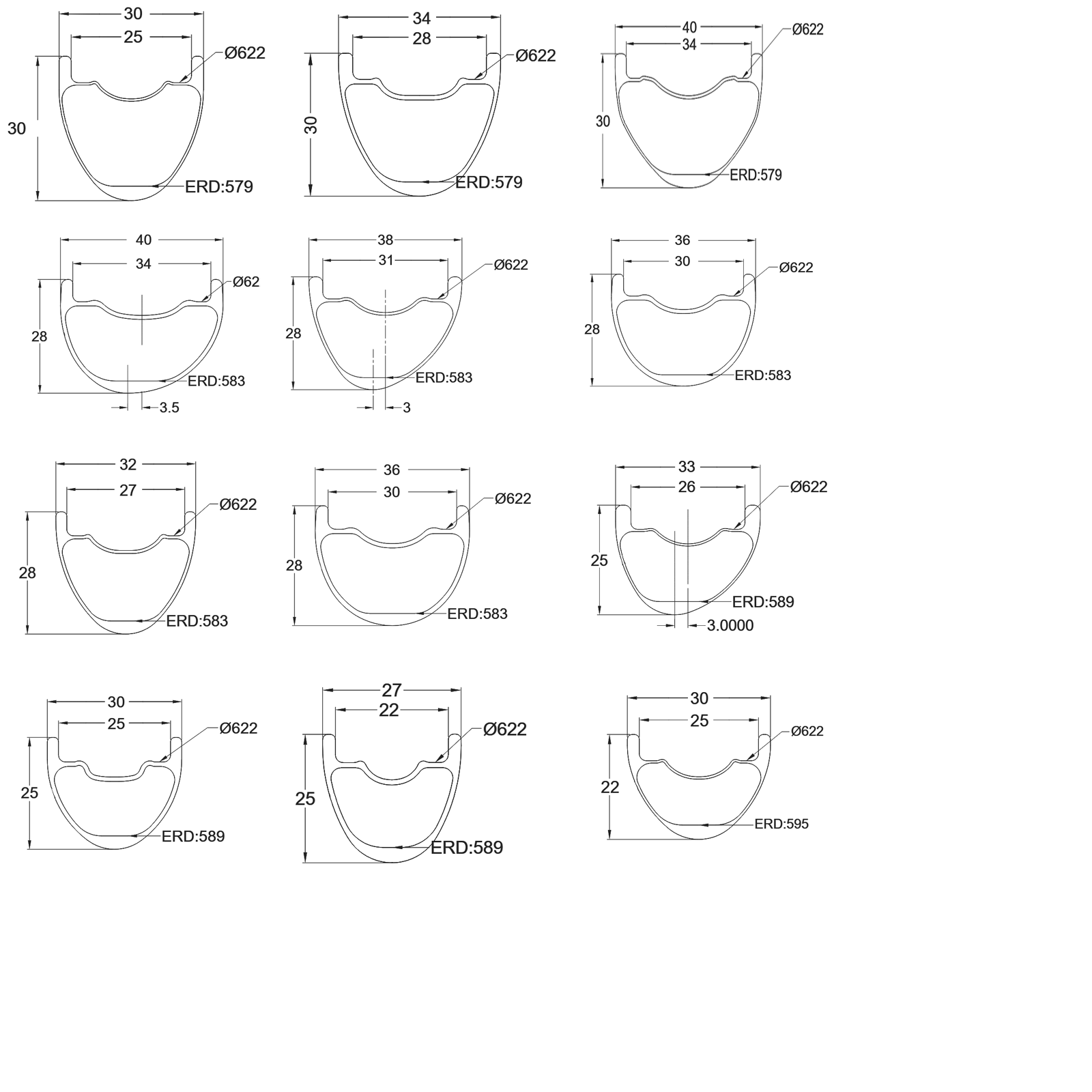

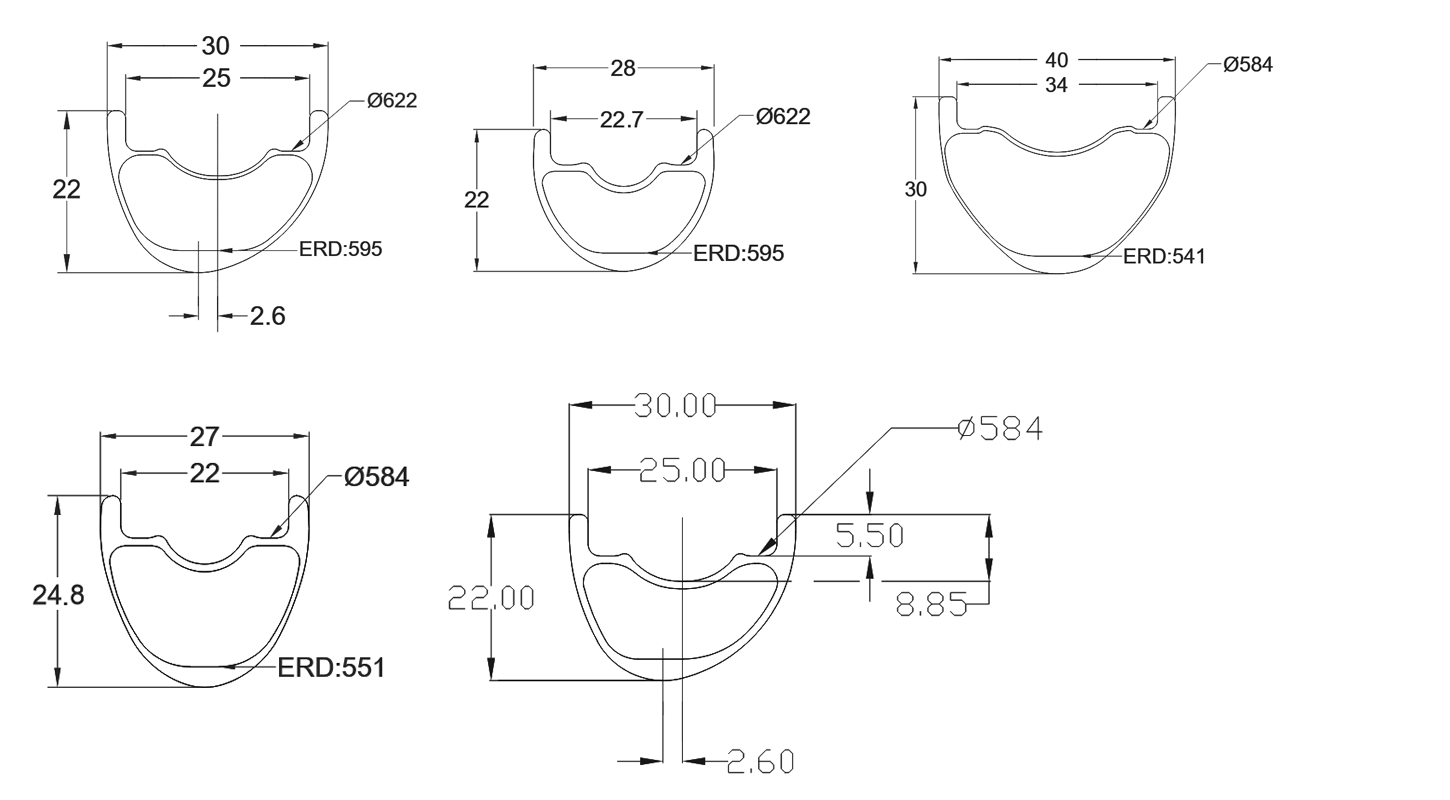

| Model | Weight (Gram) | Inner Width | Outer Width | Depth | Brake System | Available Appearance | Available Spoke Hole Counts |

| XC-M25X27HL-27.5-SL | 345±15 | 22mm | 27mm | 24.8mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-M25X27HL-27.5-UL | 265±15 | 22mm | 27mm | 24.8mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-MA22X30HL-27.5-SL | 345±15 | 25mm | 30mm | 22mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-MA22X30HL-27.5-UL | 295±15 | 25mm | 30mm | 22mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| AM-MA25X33HL-27.5-SL | 360±15 | 26mm | 33mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-MA25X33HL-27.5-UL | 320±15 | 26mm | 33mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| EN-M30X40HL-27.5-SL | 460±15 | 34mm | 40mm | 30mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| AM-M30X40HL-27.5-UL | 420±15 | 34mm | 40mm | 30mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-M22X28HL-29ER-UL | 300±15 | 22.7mm | 28mm | 22mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-MA22X30HL-29ER-NL | 360±15 | 25mm | 30mm | 22mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-MA22X30HL-29ER-SL | 310±15 | 25mm | 30mm | 22mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-MA22X30HL-29ER-UL | 255±15 | 25mm | 30mm | 22mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| XC-M22X30HL-29ER-NL | 360±15 | 25mm | 30mm | 22mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-M22X30HL-29ER-SL | 310±15 | 25mm | 30mm | 22mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-M22X30HL-29ER-UL | 255±15 | 25mm | 30mm | 22mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| XC-M25X27HL-29ER-SL | 370±15 | 22mm | 27mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-M25X27HL-29ER-UL | 285±15 | 22mm | 27mm | 25mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| XC-M20X36HL-29ER | 285±15 | 30mm | 36mm | 20mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| XC-M25X30HL-29ER-NL | 360±15 | 25mm | 30mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-M25X30HL-29ER-SL | 310±15 | 25mm | 30mm | 25mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| XC-M25X30HL-29ER-UL | 260±15 | 25mm | 30mm | 25mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| AM-MA25X33HL-29ER | 400±15 | 26mm | 33mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| TR-MA25X33HL-29ER | 380±15 | 26mm | 33mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-MA25X33HL-29ER | 340±15 | 26mm | 33mm | 25mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| AM-M25X35HL-29ER | 385±15 | 28mm | 35mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-MA25X35HL-29ER-NL | 360±15 | 30mm | 35mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-MA25X35HL-29ER-SL | 320±15 | 30mm | 35mm | 25mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| XC-MA25X35HL-29ER-UL | 280±15 | 30mm | 35mm | 25mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| XC-MA25X33HL-29ER-SL | 380±15 | 27mm | 32mm | 25mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-MA25X33HL-29ER-UL | 330±15 | 27mm | 32mm | 25mm | Disc Brake | UD | 16/18/20/21/24/28/32/36H |

| AM-M22X30HL-29ER-SL | 435±15 | 25mm | 30mm | 22mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-M22X30HL-29ER-UL | 360±15 | 25mm | 30mm | 22mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| EN-MA28X38HL-29ER-SL | 490±15 | 31mm | 38mm | 28mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| AM-MA28X38HL-29ER-UL | 450±15 | 31mm | 38mm | 28mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| EN-MA28X40HL-29ER-SL | 490±15 | 34mm | 40mm | 28mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| AM-MA28X40HL-29ER-UL | 460±15 | 34mm | 40mm | 28mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-M30X30HL-29ER-SL | 380±15 | 25mm | 30mm | 30mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-M30X30HL-29ER-UL | 345±15 | 25mm | 30mm | 30mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| AM-M30X34HL-29ER-SL | 435±15 | 28mm | 34mm | 30mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| XC-M30X34HL-29ER-UL | 350±15 | 28mm | 34mm | 30mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| EN-M30X40HL-29ER-SL | 480±15 | 34mm | 40mm | 30mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| AM-M30X40HL-29ER-UL | 440±15 | 34mm | 40mm | 30mm | Disc Brake | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

100% Customizable

Customized Weaves & Finishes:

Customized Holes:

![]()

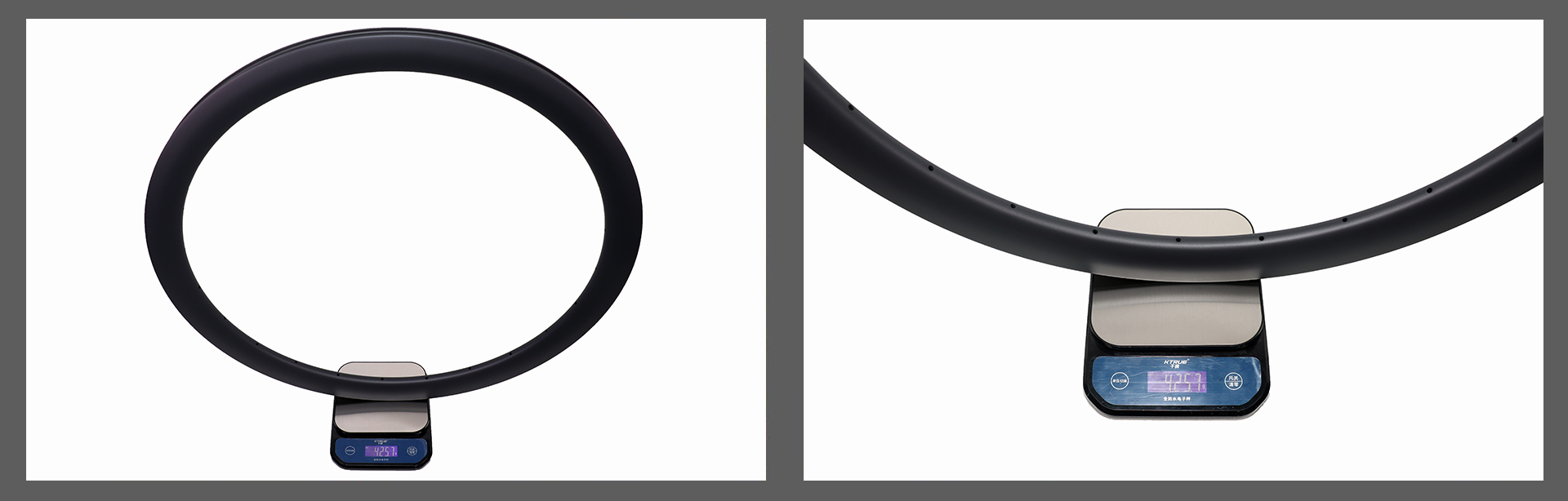

Weight Check:

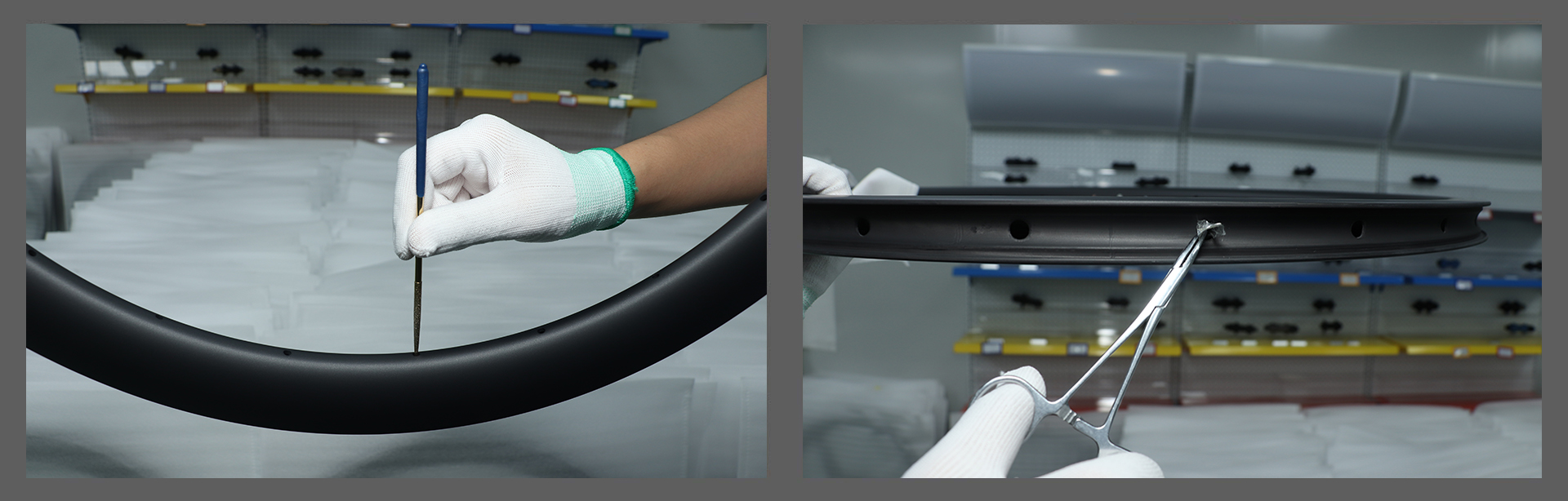

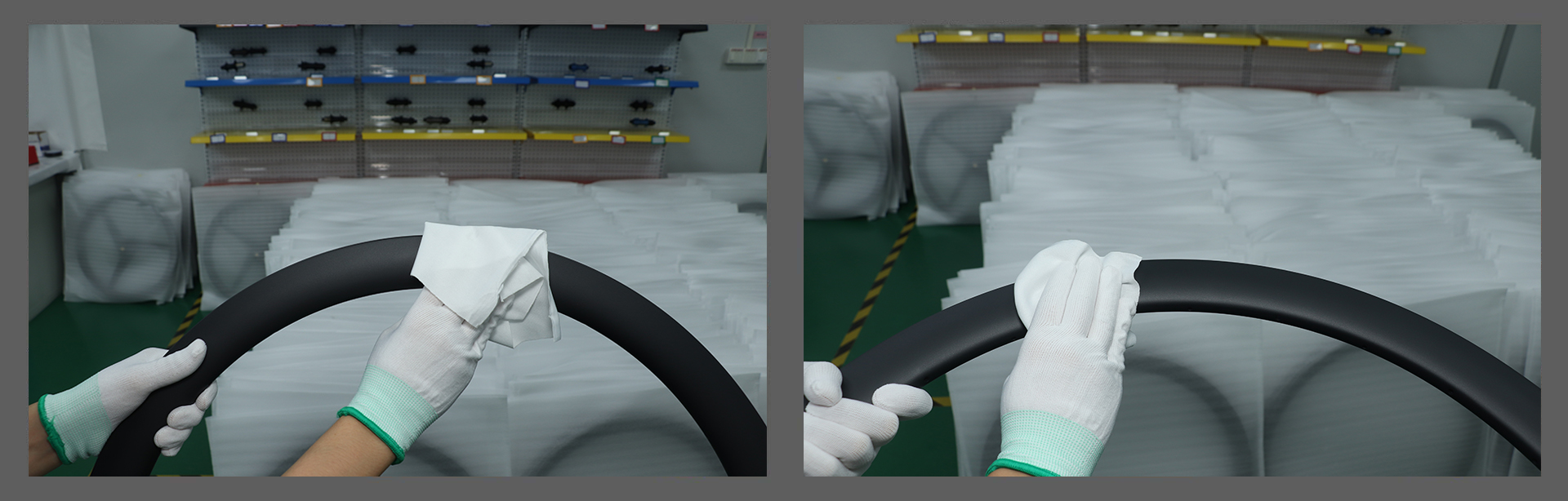

Clean burrs & residues

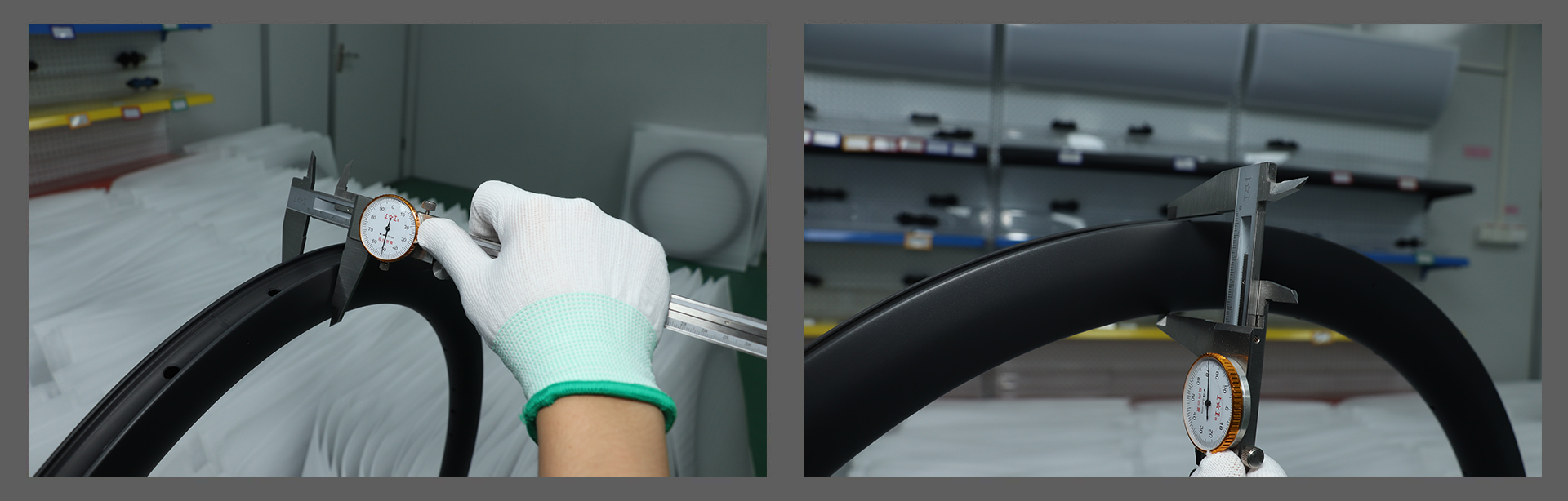

Rim Diameters Check:

Cleaning

Packing

AM-MA28X40HL-29ER-UL Product Show

We have been in carbon bicycle production industry since the year of 2015, so 10 years history and experiences.

100 workers, 30 management, 20 Engineers, 10 Sales.

Carbon bicycle rims, carbon spokes, carbon wheels, cranks and other carbon bicycle components.

Our factory area is 2500 square meters, with 2 production lines, one wheel building line.

10.000 pcs/month for carbon rims, 100.000 pcs/month for carbon spokes, 10.000 pcs/month for other carbon bicycle components like cranks, handlebars, thru axles etc.

10-15 days for carbon rims(100-200 pcs), 7-10 days for carbon spokes, 25-30 days for carbon wheels.

It depend on the product models, quantities and and other factors, takes carbon rim for example, price generate from 80-130 USD per piece.

2 years for carbo rims and wheels, 1 year for carbon spokes.

We focus on OEM/ODM service for customers mainly on Europe and American markets.

We have signed confidential agreement with our big OEM customers, so not allow to tell, but the big brands from Europe and America.

Our factory locates in Xiamen, China.