The RH-CS275T-DB is a carbon spoke hub optimized for road use. Its core advantage lies in its "deep fusion of road racing lightweight and multi-system compatibility." The main body is forged from 6061 aluminum alloy, using five-axis precision machining to eliminate redundant components. Key components such as the axle and freehub interface are constructed from AL7075 (hardness reaches HV155), offering 40% greater wear resistance than 6061. This balance of lightweight without compromising strength is achieved at a total weight of 279 ± 15g.

The front wheel features a 12*100mm diameter thru-axle, while the rear wheel features a 12*142mm diameter thru-axle. Compatible with mainstream road frames, the wheel boasts a clearance of ≤0.01mm and radial runout of ≤0.05mm at high speeds. The 24/24 hole straight-pull design incorporates dedicated carbon spoke hole placement (compatible with both T- and round-end spokes). The curved hole transitions minimize stress concentration during installation, minimizing spoke tension tolerance to within 3%. The wheel comes standard with a 36-tooth ratchet system with a 10° engagement angle, ensuring near-zero pedaling responsiveness. It supports both steel ball bearings (the company's standard configuration, rated IP54 for dust and water resistance) and ceramic bearings (an optional upgrade with a 38% reduction in friction coefficient). It's compatible with disc brakes and freehub bodies from various brands, and can also be customized with laser-engraved hub shell markings. This wheel meets the diverse needs of road cycling, from daily training to professional racing, making it an ideal component for customizing and upgrading carbon-spoke road wheels.

Fully compatible carbon spoke design:

The dedicated hole configuration is compatible with both T-head and round-head carbon spokes. The hole features a 0.5mm radius and carbon fiber reinforcement ring. T-head carbon spoke contact area is 35% greater than with standard hole configurations. Round-head carbon spokes are secured with anti-slip grooves within the hole. Both head configurations ensure uniform spoke tension distribution (≤3%). This solves the pain points of traditional hub carbon spokes, which have limited fit and are prone to loosening. The wheelset is 25% stiffer, ensuring smooth cornering at high speeds.

Dual Bearing Adaptability:

Steel ball bearings are the company's primary configuration, utilizing high-carbon chromium steel balls and rubber seals. They are IP54 dust and water resistant, and boast an 8,000km maintenance interval for road riding, making them suitable for both daily training and long-distance cycling. They offer excellent value for money. Ceramic bearings (silicon nitride ceramic balls) are an optional upgrade, boasting a friction coefficient of only 0.0013, a 42% improvement in rotational smoothness, and a 9% increase in power transmission efficiency compared to steel ball bearings. These bearings are ideal for professional riders pursuing extreme racing performance or in competitions. Both bearings are individually replaceable, ensuring flexible maintenance.

Multi-Freezer Compatibility:

Supports Shimano HG/MSR (compatible with 8-12 speed cassettes), Campagnolo N3W (compatible with Campagnolo's full range of speed systems), and S-Link XDR (compatible with 10-12 speed cassettes) for quick-change freehubs. The freehub interface features a quick-release locking mechanism, allowing tool-free replacement in under 4 minutes. This allows adaption to different drivetrain brands without having to replace the hub body, eliminating hub waste during gear upgrades.

36-Tooth Ratchet for Efficient Drive:

The default 36-tooth ratchet system features a 10° engagement angle, which is 50% more responsive than a 24-tooth ratchet. This ensures zero pedaling power lag and faster acceleration on flat roads. The ratchet teeth are made of AL7075 hard-anodized material, durable for over 100,000 cycles, ensuring long-term use without slipping and ensuring efficient power delivery for road racing.

Personalization and Durability:

The hub shell can be customized with laser engraving (brand logo, model, unique serial number, etc.). Laser engraving is performed to a depth of 0.1mm, ensuring no damage to the shell structure and resisting wear, meeting brand customization or personalization needs. The AL7075 freehub interface with nano-rust-proof coating has passed a 6-month salt spray test with no rust. The disc brake flange concentricity error is ≤0.02mm, and the braking response delay in rainy weather is ≤0.2 seconds, ensuring safe road riding.

OEM & ODM Services:

KOIBIKE have a 2000 square meters production line for hubs, 15+ R&D people and 10+ years production experiences for bicycle hubs and parts, who can provide professional OEM & ODM services for all kind of your requests.

Fast Lead Time:

KOBIKE have a 10000 pairs+ monthly capacity for bicycle hubs, as a professional bike components manufacturer and supplier, we have the ability to deliver your bulk orders within 3-5 weeks after order confirmation

Product Drawings

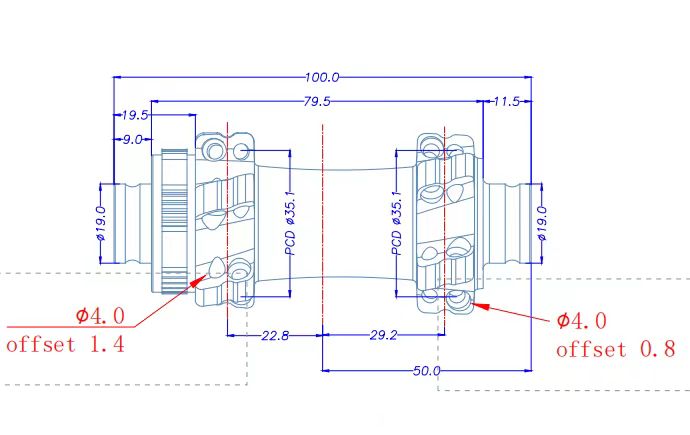

Front Hub Drawing:

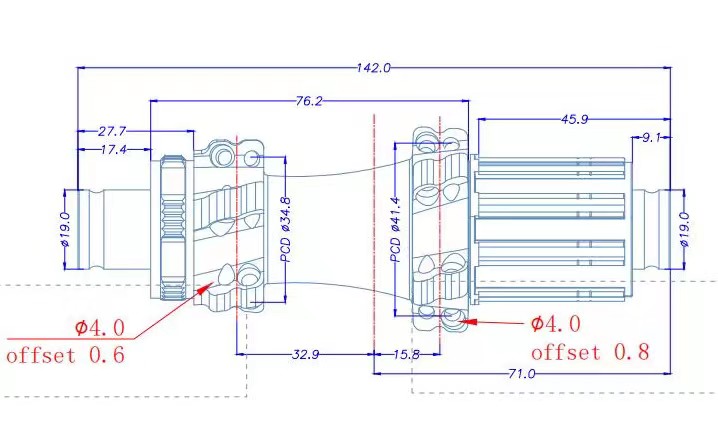

Rear Hub Drawing:

Application areas for the RH-CS275T-DB rim brake hubs:

Road Racing:

A lightweight of 279g, the low-drag properties of ceramic bearings, and the efficient transmission of a 36-tooth ratchet combine with the aerodynamic advantages of carbon spoke wheels to significantly improve acceleration and cruising efficiency in road races and criterium criteriums, giving riders an edge in competitive events. Multi-freehub compatibility allows for adaptability to different team shifting configurations. High-end road bike upgrades:

As a core transmission component for high-end road bikes, its multi-driver body compatibility and carbon spoke compatibility enhance the overall vehicle's product value. A steel bearing version meets the needs of the mass market, while a ceramic bearing version serves as a performance upgrade for high-end models. Custom laser engraving services also allow for unique branding, enhancing product differentiation.

RH: Road Hub

MH: MTB Hub

SS: Stainless Steel Spoke

CS: Carbon Spoke

RB: Rim Brake

DB: Disc Brake

T: T Head Design

| Model | Intended Use | Brake System | Holes | Weight | SP/J-Bend | Bearings | Materials | QR/Thru Axle Size | Freehub Body |

RH-SS280-RB | Road Rim Brake Wheels | Rim Brake | 20/24 | 284±5g | Straight Pull | Steel/Ceramic | Aluminum 6061+7075 | QR 9*100/10*130mm | SHIMANO HG/MSR/N3W/XDR |

RH-CS300-RB | Road Rim Brake Wheels | Rim Brake | 18/21(2:1) | 298±5g | Straight Pull | Steel/Ceramic | Aluminum 6061+7075 | QR 9*100/10*130mm | SHIMANO HG/MSR/N3W/XDR |

RH-SS260-DB | Road Disc Brake Wheels | Disc Brake | 24/24 | 269±5g | Straight Pull | Steel/Ceramic | Aluminum 6061+7075 | Thru Axle 12*100/12*142mm | SHIMANO HG/MSR/N3W/XDR |

RH-CS275-DB | Road Disc Brake Wheels | Disc Brake | 20/20 | 279±5g | Straight Pull | Steel/Ceramic | Aluminum 6061+7075 | Thru axle 12*100/12*142mm | SHIMANO HG/MSR/N3W/XDR |

RH-CS275T-DB | Road Disc Brake Wheels | Disc Brake | 20/20 | 283±5g | Straight Pull | Steel/Ceramic | Aluminum 6061+7075 | Thru axle 12*100/12*142mm | SHIMANO HG/MSR/N3W/XDR |

| RH-SS330-DB | Road Disc Brake Wheels | Disc Brake | 24/24 | 313±5g | Straight Pull | Steel/Ceramic | Aluminum 6061+7075 | Thru axle 12*100/12*142mm | SHIMANO HG/MSR/N3W/XDR |

| MH-SS310-Boost | MTB XC Wheels | Disc Brake | 28/28 | 306±5g | Straight Pull | Steel/Ceramic | Aluminum 6061+7075 | Thru axle 15*100/12*148mm | SHIMANO HG/MS/XD |

| MH-CS320T-Boost | MTB XC Wheels | Disc Brake | 24/24 | 330±5g | Straight Pull | Steel/Ceramic | Aluminum 6061+7075 | Thru axle 15*100/12*148mm | SHIMANO HG/MS/XD |

We have been in carbon bicycle production industry since the year of 2015, so 10 years history and experiences.

100 workers, 30 management, 20 Engineers, 10 Sales.

Carbon bicycle rims, carbon spokes, carbon wheels, cranks and other carbon bicycle components.

Our factory area is 2500 square meters, with 2 production lines, one wheel building line.

10.000 pcs/month for carbon rims, 100.000 pcs/month for carbon spokes, 10.000 pcs/month for other carbon bicycle components like cranks, handlebars, thru axles etc.

10-15 days for carbon rims(100-200 pcs), 7-10 days for carbon spokes, 25-30 days for carbon wheels.

It depend on the product models, quantities and and other factors, takes carbon rim for example, price generate from 80-130 USD per piece.

2 years for carbo rims and wheels, 1 year for carbon spokes.

We focus on OEM/ODM service for customers mainly on Europe and American markets.

We have signed confidential agreement with our big OEM customers, so not allow to tell, but the big brands from Europe and America.

Our factory locates in Xiamen, China.