The FB25X65-26ER is an innovative product born from this robust manufacturing system. It combines the lightweight, rigid, and aerodynamically optimized pursuits of road carbon rims with the demanding requirements of extra-wide support, impact resistance, and low-temperature stability required of snow rims. Utilizing aviation-grade Toray T700/T800 carbon fiber, structural stress distribution is optimized through Finite Element Analysis (FEA) to ensure superior performance even in extreme -30°C conditions. Whether used for branded OEM applications, race equipment upgrades, or high-end custom frames, the FB25X65-26ER demonstrates exceptional engineering value and market competitiveness.

Extra-wide 65mm external width:

Provides strong sidewall support for 4.0–5.0-inch tires, significantly improving flotation and handling stability on snow, sand, and muddy roads.

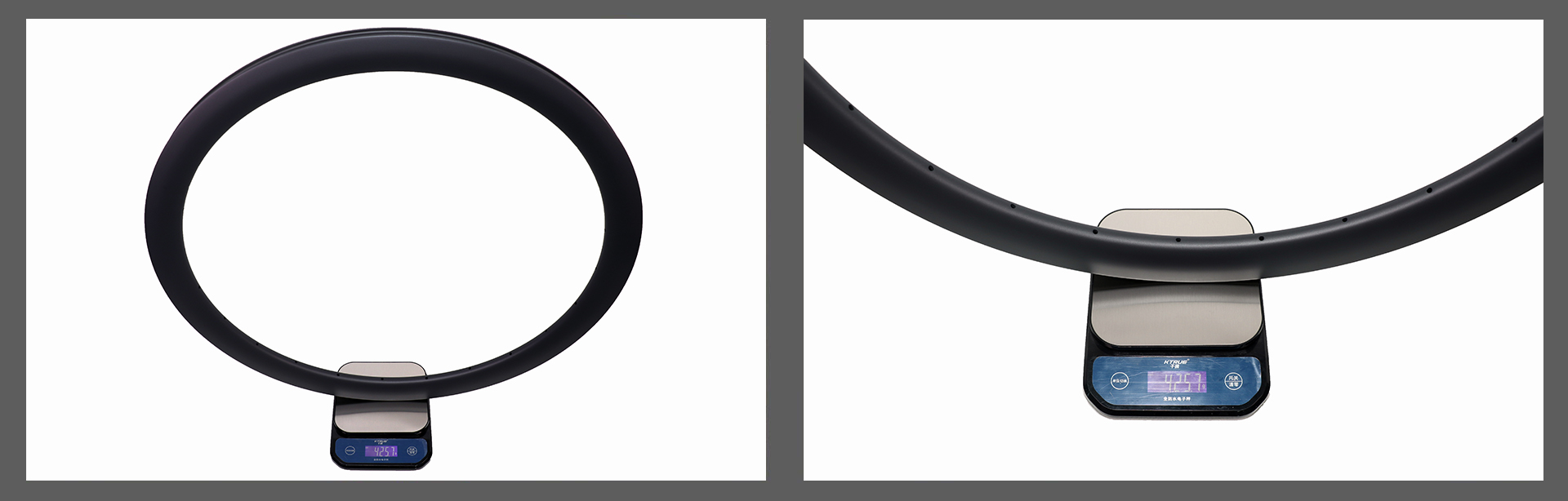

A breakthrough in carbon fiber lightweighting: weighing only 600g (±15g) per rim, it's over 30% lighter than traditional aluminum rims, significantly improving riding efficiency and overall vehicle responsiveness.

Optimized Braking:

Adapted for snow-specific disc brake pads, increasing the braking contact area. The surface has been tested for low-temperature friction coefficient, ensuring stable braking even on ice and snow, reducing stopping distance by approximately 20% compared to standard rims.

Superior Grip Design:

Increases contact area with the snow; dense, fine grooves effectively break through the ice and embed it into the snow, providing strong grip.

Various High-End Paint Options:

Available in UD, marble, 12K straight, and 12K twill finishes, meeting brand differentiation and customization needs.

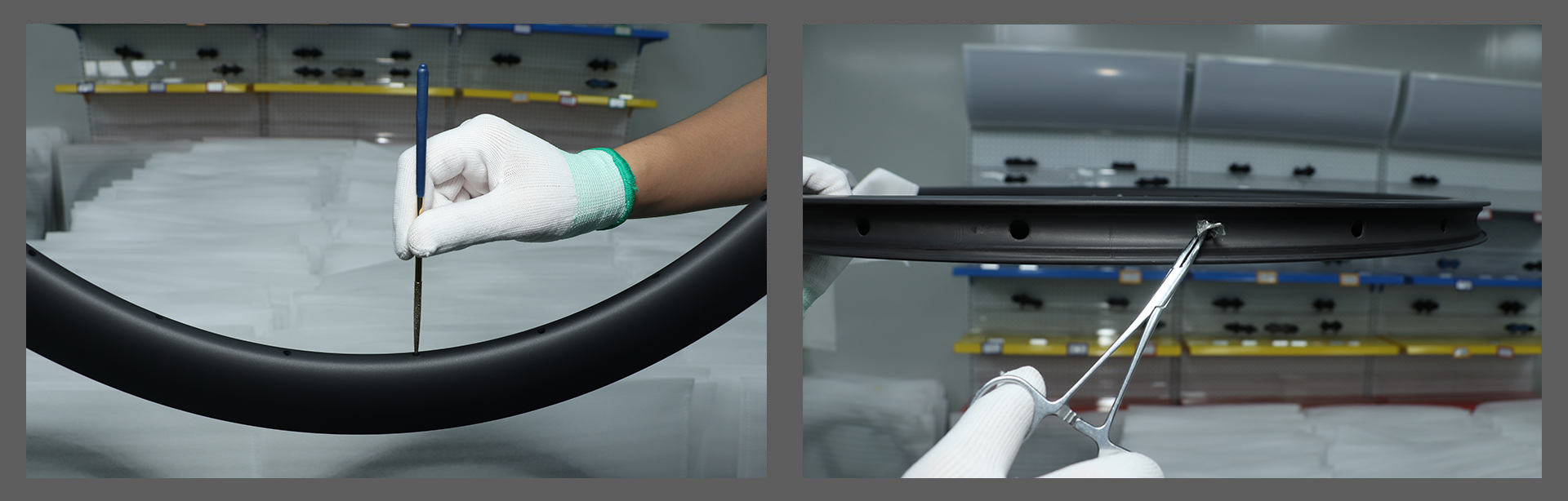

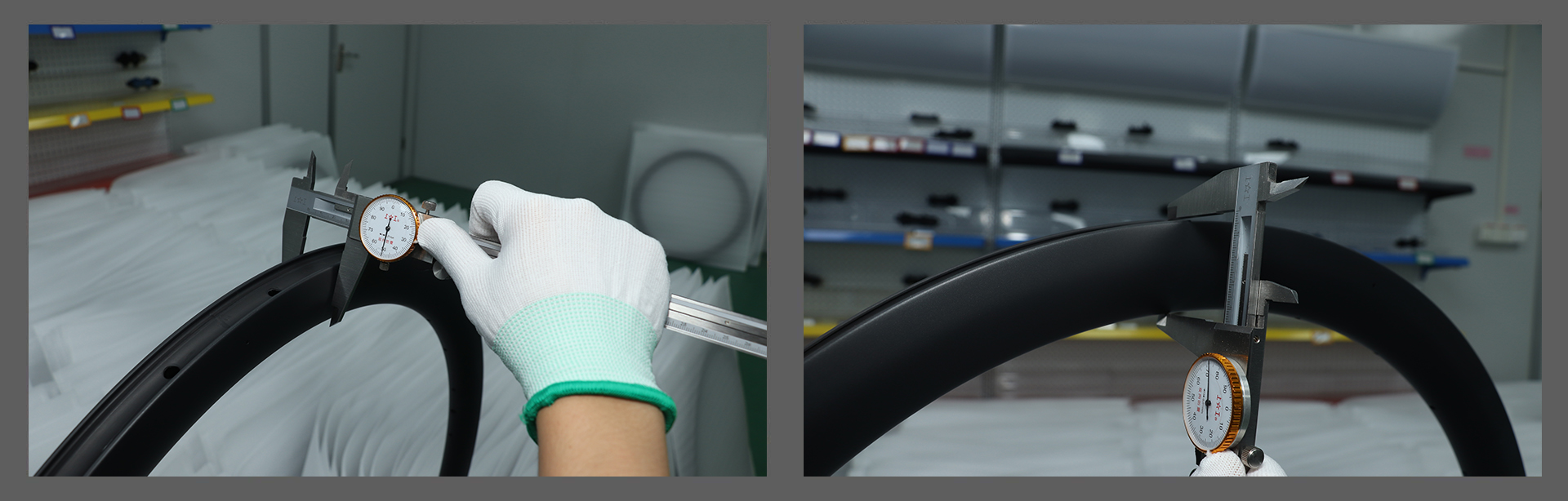

Strict Quality Control:

KOBIKE do 100% tire pressure(150 PSI), flatness(<0.2mm) and roundness(<0.2mm) inspections before shipping, also offering 2 years warranty for our carbon rims.

Rim Height and Profile:

The 25mm low-profile design prioritizes lateral stiffness and stability over aerodynamics, ideal for the low-speed, high-torque characteristics of snow cycling.

External Width and Tubeless Ready Monocoque Construction: 65mm ultra-wide outer diameter, using a vacuum-molded monocoque process, and seamless construction enhances airtightness and overall strength.

Tire Size Recommendation:

Suitable for 26-inch wheels, 4.0–5.0-inch tires are recommended, with tire pressures as low as 5–15 psi for optimal contact patch and cushioning.

Rim Structure and Rigidity:

Utilizing a double-layer carbon fiber reinforcement layer, with a focus on strengthening the tire bed and spoke hole areas, lateral rigidity is approximately 40% higher than similar-sized aluminum rims, effectively reducing pedaling deflection.

Brake Track Design:

Optimized specifically for disc brake systems, the absence of a brake track reduces unnecessary weight while also preventing brake fade associated with carbon brake tracks in cold temperatures.

Aerodynamic Considerations:

While not a high-speed aero wheel, the wide profile still helps guide airflow at low speeds, reducing local turbulence and improving overall vehicle stability.

Application areas for the FB25X65-26ER carbon bicycle rim:

Arctic & Snow Cycling:

Designed for winter polar expeditions and fat bike racing, it provides excellent flotation and traction in deep snow.

Desert & Beach Crossing:

The ultra-wide 65mm rim, when combined with low tire pressure, allows for a "water-skimming" ride on soft sand, making it widely used in desert expeditions and coastal cycling.

Gravel & Bikepacking:

Suitable for extreme mixed terrain, such as frozen soil, gravel, and mud, making it the ultimate choice for long-distance adventure cyclists.

Brand OEM/ODM Cooperation: Suitable for private label production or custom development for high-end domestic and international bicycle brands, tuners, and racing teams. KOIBIKE provides full-cycle support from design to delivery.

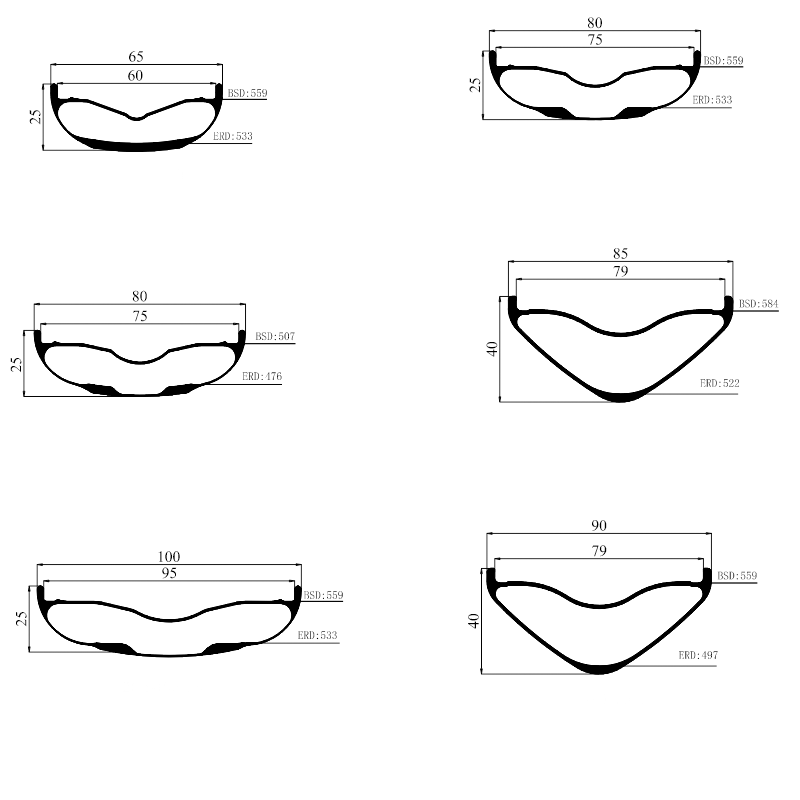

| Model | Weight (Gram) | Brake System | Inner Width | Outer Width | Depth | Available Appearance | Available Spoke Hole Counts |

| FB25X80-24ER | 580±15g | Disc Brake | 75mm | 80mm | 25mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| FB25X65-26ER | 600±15g | Disc Brake | 60mm | 65mm | 25mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| FB25X80-26ER | 680±15g | Disc Brake | 75mm | 80mm | 25mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| FB25X100-26ER | 750±15g | Disc Brake | 95mm | 100mm | 22mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

FB28X80-27.5ER | 615±15g | Disc Brake | 74mm | 80mm | 28mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

FB40X85-27.5ER | 660±15g | Disc Brake | 79mm | 85mm | 40mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

100% Customizable

Customized Weaves & Finishes:

Customized Laser Engraving Brake Track:

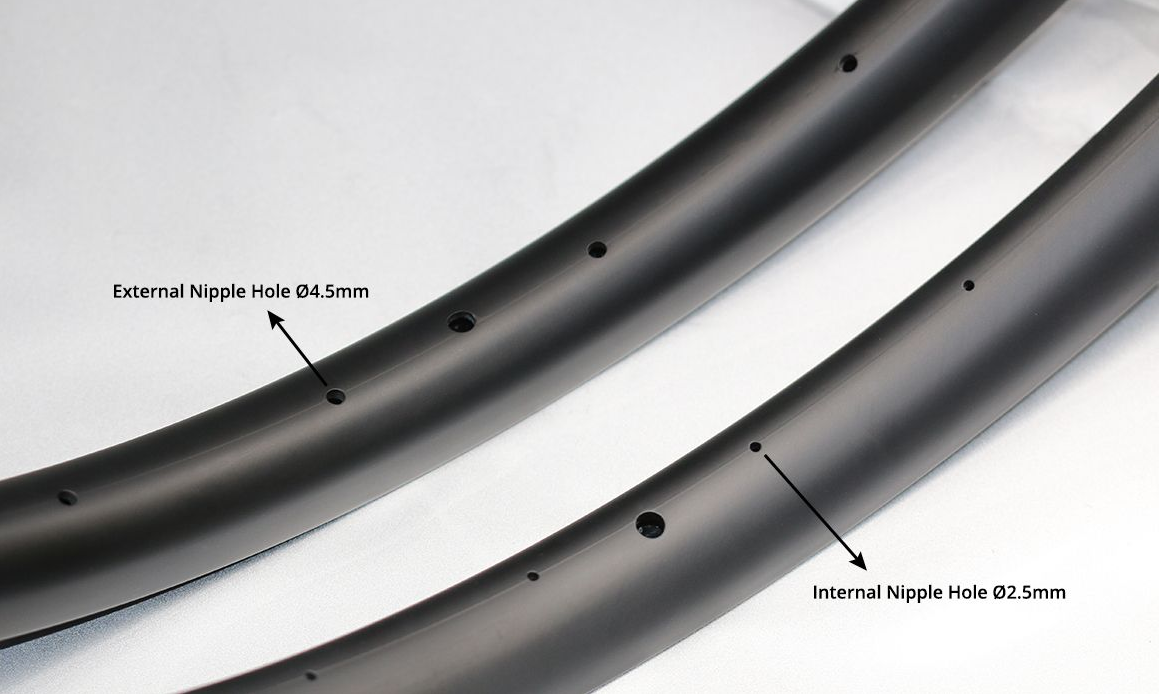

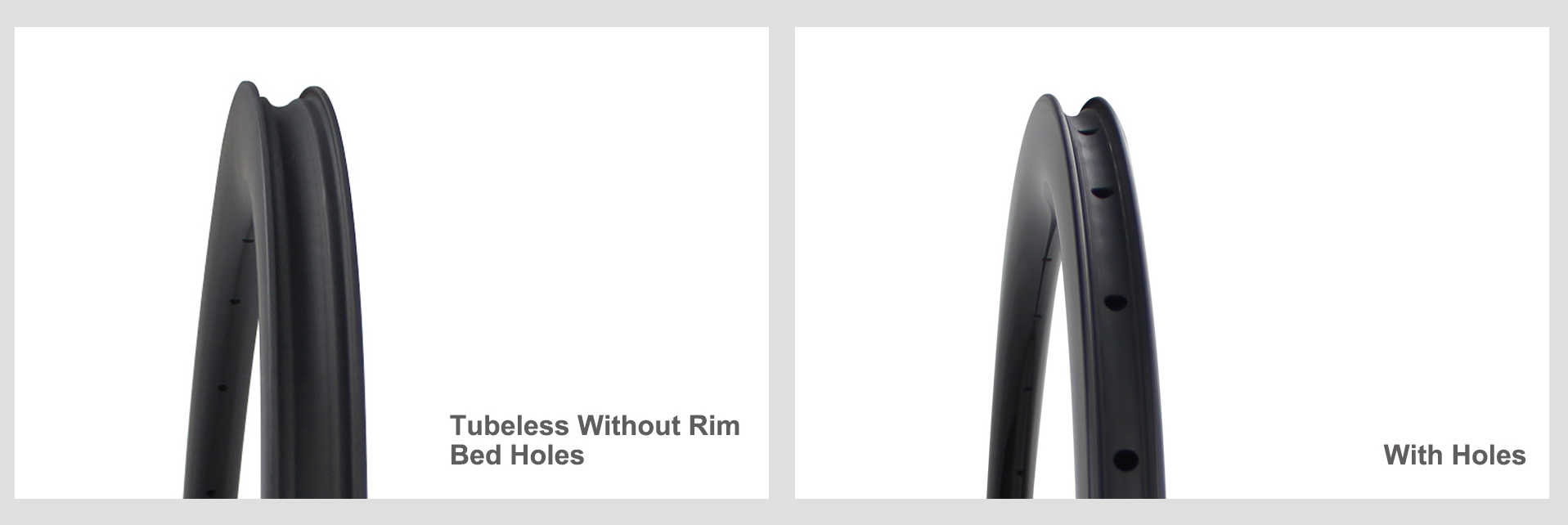

Customized Holes:

![]()

Weight Check:

Clean burrs & residues

Rim Diameters Check:

Cleaning & Packing

We have been in carbon bicycle production industry since the year of 2015, so 10 years history and experiences.

100 workers, 30 management, 20 Engineers, 10 Sales.

Carbon bicycle rims, carbon spokes, carbon wheels, cranks and other carbon bicycle components.

Our factory area is 2500 square meters, with 2 production lines, one wheel building line.

10.000 pcs/month for carbon rims, 100.000 pcs/month for carbon spokes, 10.000 pcs/month for other carbon bicycle components like cranks, handlebars, thru axles etc.

10-15 days for carbon rims(100-200 pcs), 7-10 days for carbon spokes, 25-30 days for carbon wheels.

It depend on the product models, quantities and and other factors, takes carbon rim for example, price generate from 80-130 USD per piece.

2 years for carbo rims and wheels, 1 year for carbon spokes.

We focus on OEM/ODM service for customers mainly on Europe and American markets.

We have signed confidential agreement with our big OEM customers, so not allow to tell, but the big brands from Europe and America.

Our factory locates in Xiamen, China.