KOIBIKE Factory Trading Company independently develops and produces these wide snow rims in its own factory. As a leading manufacturer, we have a mature carbon fiber processing supply chain and can efficiently handle both bulk orders and custom requirements from B2B customers. The rims are constructed from Toray's low-temperature-resistant carbon fiber, formed using a special lamination process. The 25mm low profile optimizes steering response, while the 100mm external width and 95mm internal width create an "extra-fat" design specifically designed for 3.5-4.8-inch wide snow tires, increasing their contact patch and improving flotation. The vacuum-coated, one-piece construction reduces the risk of leaks, and the UD paint finish has been tested for low-temperature durability, ensuring stable performance in extreme cold conditions. The factory supports customization of spoke hole counts and brake track specifications, providing comprehensive support from production to after-sales service for bicycle manufacturers and snow equipment dealers.

Extreme Flotation:

The 95mm internal width is compatible with extra-wide snow tires, providing a 60% increase in contact patch compared to conventional snow rims. The rims maintain stable buoyancy even in 30cm-deep snow, reducing the risk of sinking and improving maneuverability.

Low Profile Handling Advantages:

The 25mm low profile design lowers the center of gravity, resulting in more responsive steering and more stable roll control during cornering, making them ideal for riding on complex snowy terrain.

Cold-Resistant and Durable Material:

Toray carbon fiber has been tested at -40°C and shows no signs of brittleness. The UD paint finish resists freeze-thaw cycles, remaining resistant to peeling and cracking during repeated hot and cold weather, extending its service life.

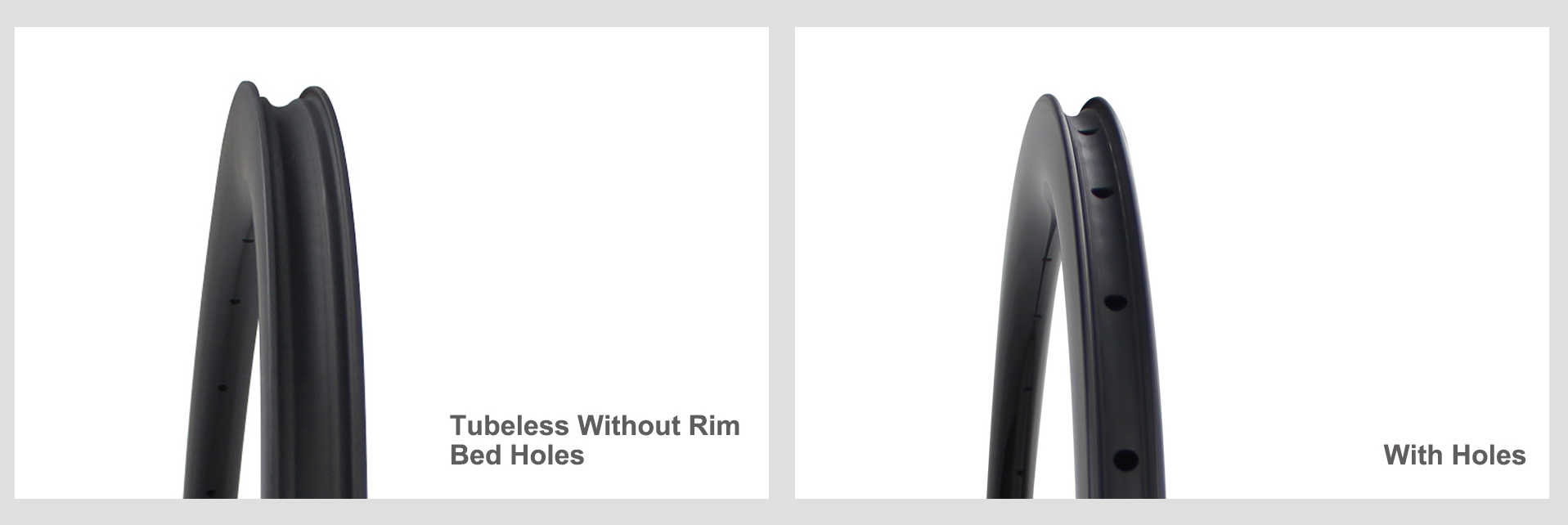

Vacuum Safety Guarantee:

The vacuum-molded, one-piece structure with dedicated sealing grooves ensures stable airtightness even at low temperatures, reducing leaks by 40% compared to traditional tube-based systems and reducing the need for repairs on snowy roads.

Flexible Customization:

Our in-house factory offers custom spokes with 16 to 36 holes to accommodate various wheel weaves. Brake track width can be adjusted as needed to meet the personalized fit needs of B-end customers.

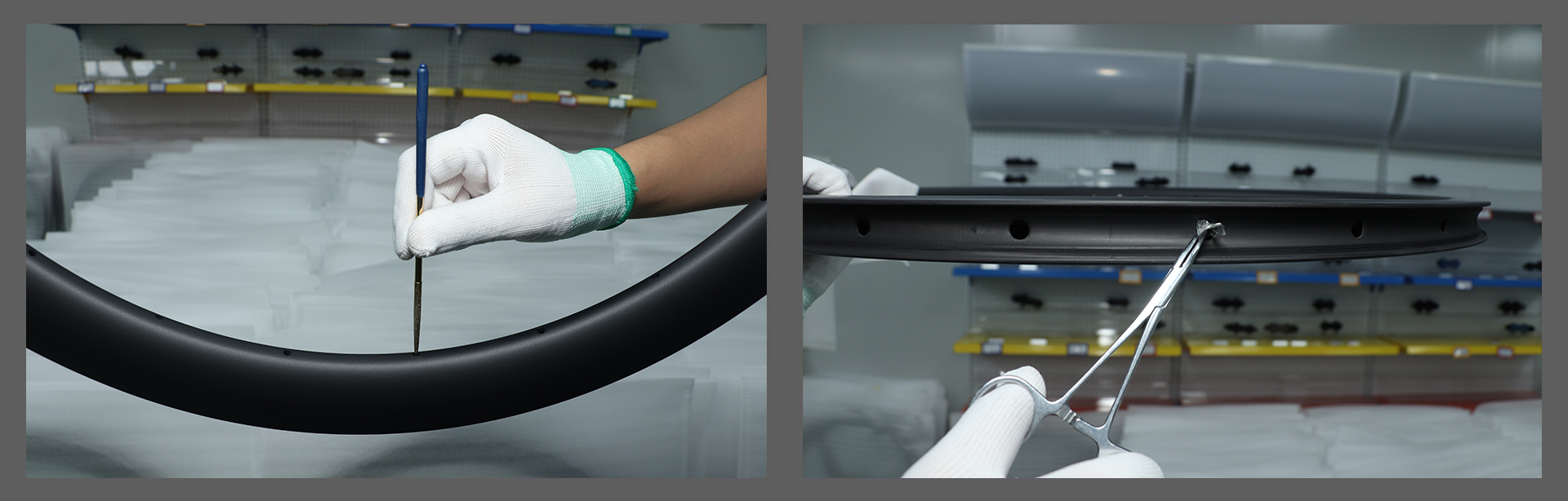

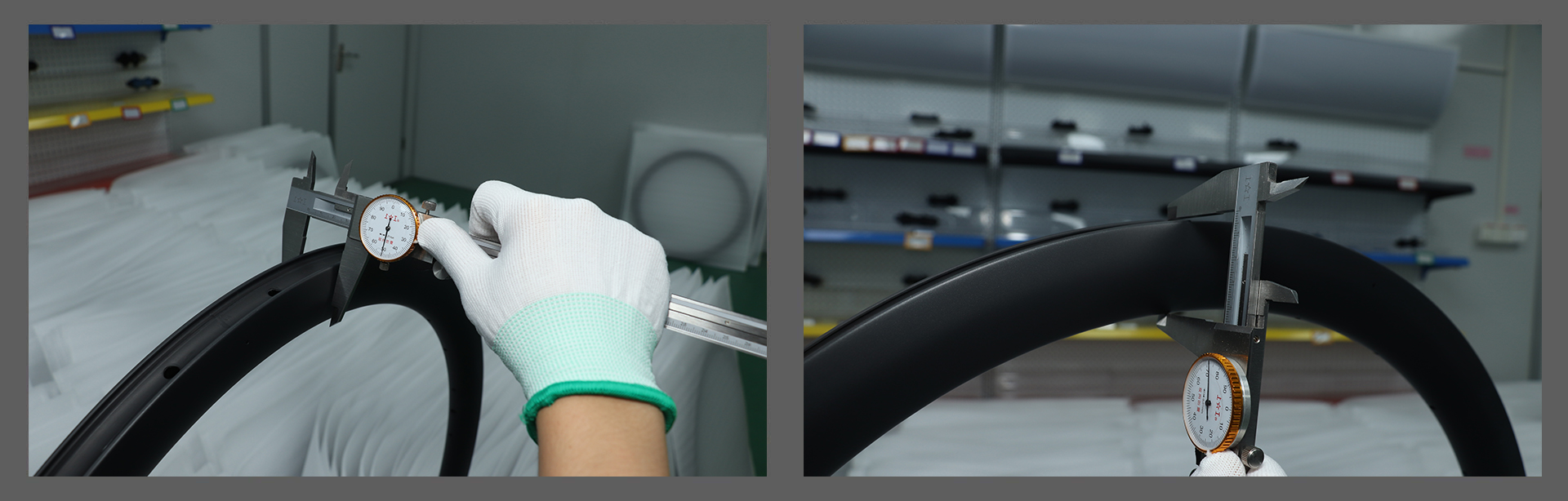

Strict Quality Control:

KOBIKE do 100% tire pressure(150 PSI), flatness(<0.2mm) and roundness(<0.2mm) inspections before shipping, also offering 2 years warranty for our carbon rims.

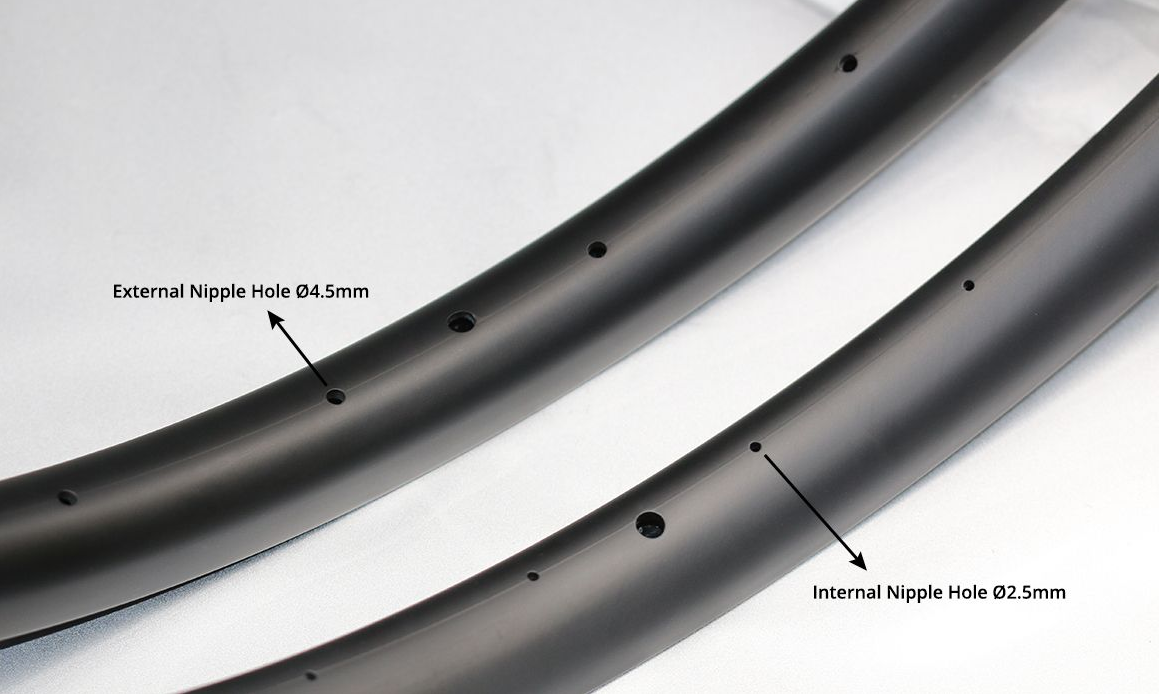

Spoke Hole Design:

Available in a variety of sizes, from 16 to 36 holes, the holes are reinforced with a double layer of carbon fiber with a pull-out strength of 300kg. This evenly distributes spoke tension, maintains rim roundness under wide tire pressure, and is suitable for the intense stresses of snowy riding.

Rim Appearance: The entire rim is covered in a UD matte paint finish, revealing a naturally visible carbon fiber texture. The surface is treated with a low-temperature, wear-resistant coating to resist scratches from snow and gravel, maintaining its appearance intact over long-term use.

Brake Track Construction:

Compatible with snow-specific disc brake pads, the braking contact area is increased by 25%, maintaining a stable friction coefficient at low temperatures, ensuring smooth downhill braking and ensuring safe riding.

Rim Structure:

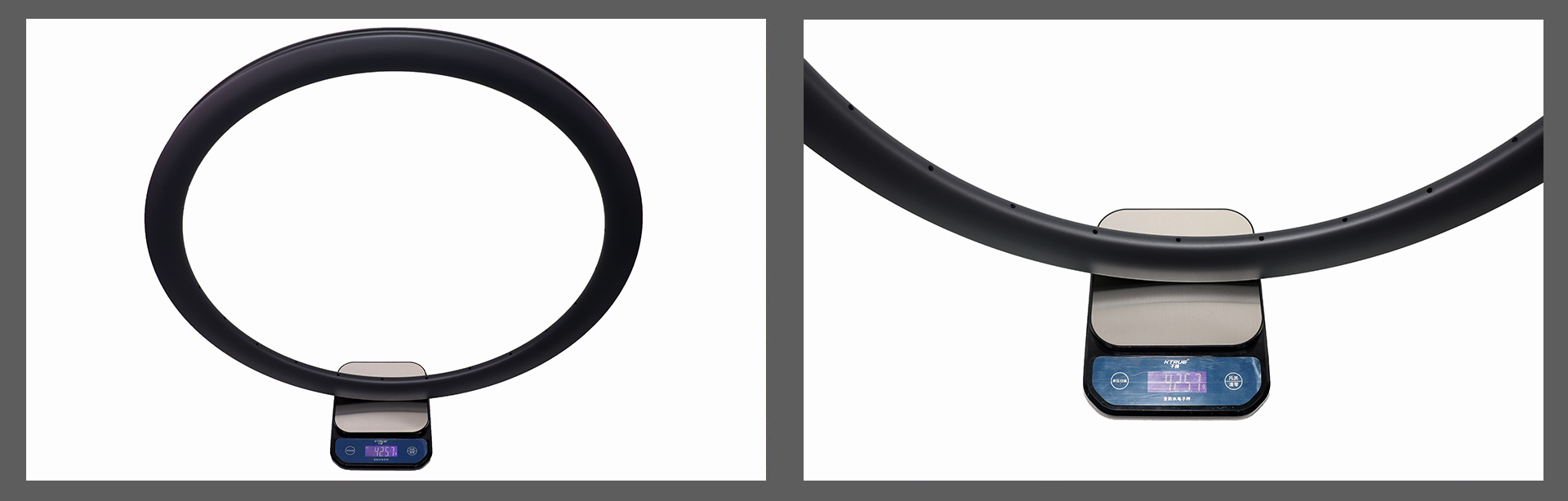

A 25mm low profile and a 100mm outer width create a "flat" streamlined shape. The carbon fiber layers distribute force radially, resulting in a lightweight design (750 ± 15g) while increasing torsional strength by 40%, capable of supporting a 120kg rider without noticeable deformation.

Vacuum Sealing Details:

Multiple annular sealing grooves on the inside of the rim tightly engage the tubeless tire bead, maintaining an airtight seal even at low temperatures and improving tire pressure stability by 30% compared to conventional tubeless rims.

Application areas for the FB25X100-26ER carbon bicycle rim:

Professional Snow Biking: Suitable for high-intensity riding such as off-roading and ice exploration. Its extra-wide size accommodates large tires, making it an ideal choice for professional riders, easily navigating complex terrain such as deep snow and ice.

Snow Scenic Area Rental Equipment: Snow bike rental locations in scenic areas are equipped with these rims, improving rider safety and experience, reducing snow-sinking problems, and lowering maintenance costs.

Polar Scientific Expedition Logistics: Providing rims for polar expedition teams' commuter bicycles, ensuring reliable performance in extreme low temperatures and deep snow, and ensuring efficient mobility.

B-End Vehicle Assembly: Bicycle manufacturers equip these rims on professional snow bike models, leveraging their extra-wide flotation to enhance product competitiveness and attract snow bike enthusiasts.

Snow Racing Equipment: As the designated rim for snow bike racing, its low-profile handling and high flotation combine to help athletes maximize their performance on complex courses.

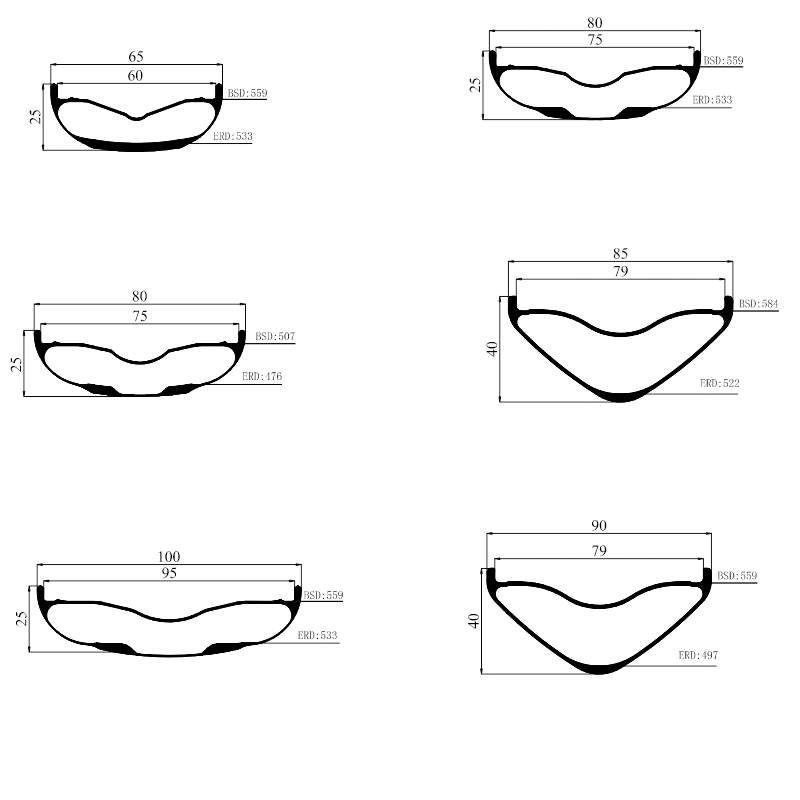

| Model | Weight (Gram) | Brake System | Inner Width | Outer Width | Depth | Available Appearance | Available Spoke Hole Counts |

| FB25X80-24ER | 580±15g | Disc Brake | 75mm | 80mm | 25mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| FB25X65-26ER | 600±15g | Disc Brake | 60mm | 65mm | 25mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| FB25X80-26ER | 680±15g | Disc Brake | 75mm | 80mm | 25mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

| FB25X100-26ER | 750±15g | Disc Brake | 95mm | 100mm | 22mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

FB28X80-27.5ER | 615±15g | Disc Brake | 74mm | 80mm | 28mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

FB40X85-27.5ER | 660±15g | Disc Brake | 79mm | 85mm | 40mm | UD/Marble/12K/Twill | 16/18/20/21/24/28/32/36H |

100% Customizable

Customized Weaves & Finishes:

Customized Laser Engraving Brake Track:

Customized Holes:

![]()

Weight Check:

Clean burrs & residues

Rim Diameters Check:

Cleaning:

Packing:

FB25X100-26ER Product Show

We have been in carbon bicycle production industry since the year of 2015, so 10 years history and experiences.

100 workers, 30 management, 20 Engineers, 10 Sales.

Carbon bicycle rims, carbon spokes, carbon wheels, cranks and other carbon bicycle components.

Our factory area is 2500 square meters, with 2 production lines, one wheel building line.

10.000 pcs/month for carbon rims, 100.000 pcs/month for carbon spokes, 10.000 pcs/month for other carbon bicycle components like cranks, handlebars, thru axles etc.

10-15 days for carbon rims(100-200 pcs), 7-10 days for carbon spokes, 25-30 days for carbon wheels.

It depend on the product models, quantities and and other factors, takes carbon rim for example, price generate from 80-130 USD per piece.

2 years for carbo rims and wheels, 1 year for carbon spokes.

We focus on OEM/ODM service for customers mainly on Europe and American markets.

We have signed confidential agreement with our big OEM customers, so not allow to tell, but the big brands from Europe and America.

Our factory locates in Xiamen, China.