Recycled Carbon Fiber: Turning Waste into Wheels

One of the biggest breakthroughs in sustainable carbon fiber wheel production is the adoption of recycled carbon fiber (rCF). Traditionally, carbon fiber—known for its strength-to-weight ratio—has been a challenge to recycle: once cured (hardened) in the manufacturing process, it’s difficult to break down without losing structural integrity. But new technologies are changing that.

Brands like Belgium’s Recycled Carbon Fiber Company (RCC) and U.S.-based Vartega now use chemical and mechanical processes to recover carbon fiber from old wind turbine blades, aircraft parts, and even discarded bike frames. This recycled material is then transformed into carbon fiber sheets (prepregs) that meet the strict performance standards of bike wheel manufacturing. In 2024, leading wheel brand Zipp launched its 303 Firecrest rCF wheel, made with 40% recycled carbon fiber. Testing showed the wheel matched the stiffness and weight of its virgin carbon fiber counterpart—while cutting carbon emissions by 35% during production.

“For years, carbon fiber waste was seen as a dead end,” says Emma Lindgren, sustainability director at Zipp. “Now, we’re turning that waste into wheels that perform just as well as new. It’s a win for cyclists and the planet.”

Energy-Efficient Manufacturing: Cutting Carbon at the Source

Beyond materials, wheel makers are overhauling their manufacturing processes to reduce energy use and emissions. Traditional carbon fiber wheel production relies on high-temperature ovens (autoclaves) to cure the carbon fiber, which consume large amounts of electricity and release greenhouse gases. Today, brands are adopting low-temperature curing and out-of-autoclave (OOA) technologies to slash energy waste.

Italian brand Campagnolo, for example, redesigned its wheel production facility in Vicenza to use OOA curing for its Bora Ultra WTO wheels. By eliminating the need for high-pressure autoclaves and using LED-based heating systems, the company reduced energy consumption per wheel by 28%. Meanwhile, U.S. brand Enve implemented solar panels at its Utah factory, covering 60% of the energy needed to power its carbon fiber wheel 生产线. The result? A 22% drop in carbon emissions per wheel since 2022.

These changes aren’t just good for the environment—they’re also cost-effective. “Energy efficiency reduces our operational costs, which lets us keep prices competitive for cyclists,” explains Marco Bertolazzi, Campagnolo’s manufacturing chief. “Sustainability doesn’t have to be a luxury.”

Circular Design: Wheels That Last (and Get Reborn)

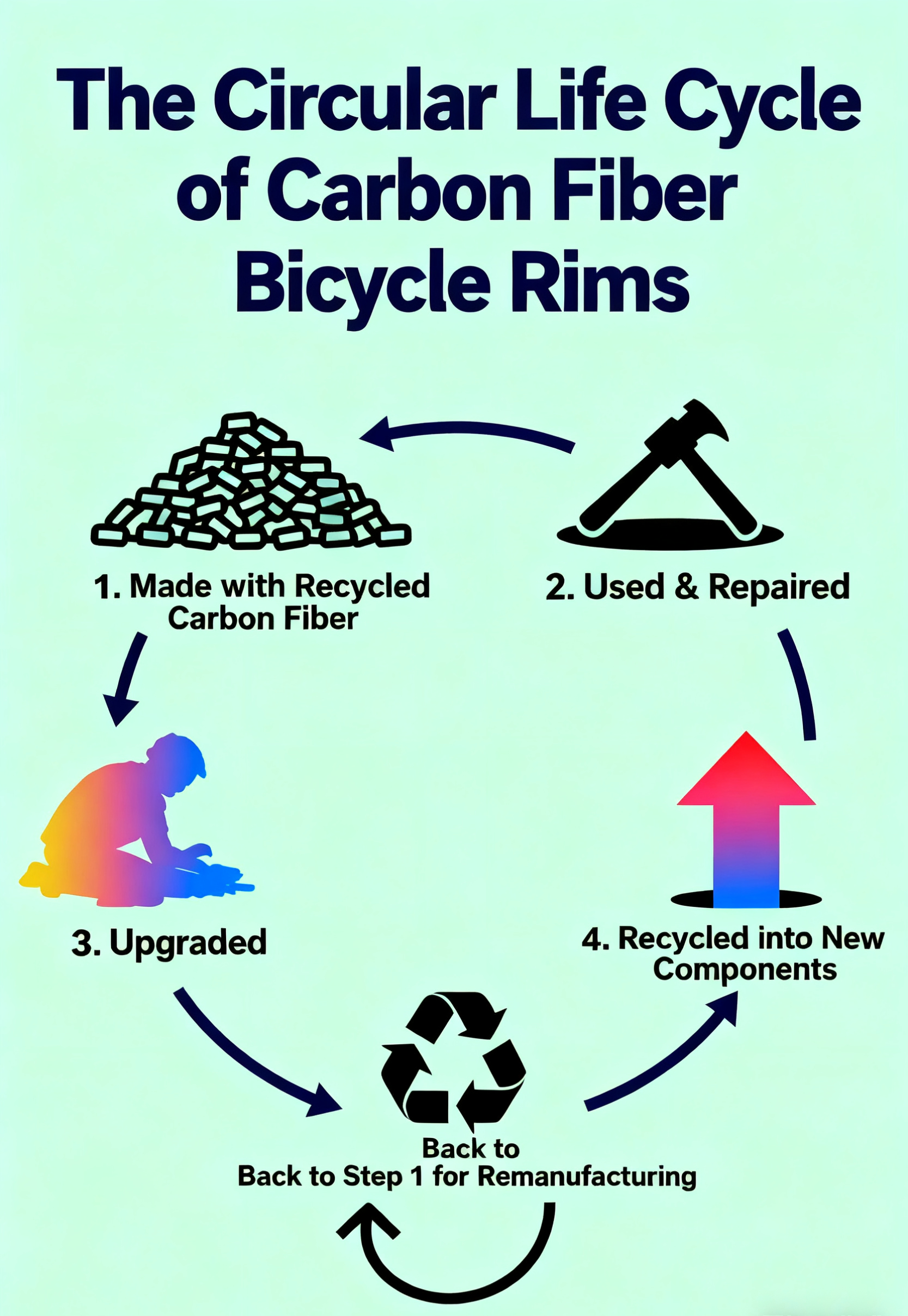

Sustainability isn’t just about how wheels are made—it’s about how long they last, and what happens to them when they’re no longer usable. To address this, brands are focusing on circular design: making wheels easier to repair, upgrade, and recycle at the end of their life.

Specialized, a leader in cycling innovation, launched its “Wheel Lifetime Program” in 2023. The program allows cyclists to send in damaged carbon fiber wheels (even non-Specialized models) for repair or recycling. For repairable wheels, Specialized uses precision patching techniques to fix cracks or dents—extending the wheel’s life by 2–3 years on average. For wheels that can’t be repaired, the brand partners with Vartega to recycle the carbon fiber into new components, like handlebars or seat posts.

Other brands are designing wheels with modularity in mind. Dutch startup Van Rysel’s Carbon R500 wheel features a replaceable rim bed: if the rim gets damaged, cyclists can swap out just the bed instead of buying a whole new wheel. This “replace, don’t replace” model cuts down on waste and saves cyclists money.

“Circularity is about rethinking ‘end of life’ as ‘new beginning’,” says Lucas de Vries, founder of Van Rysel. “A wheel shouldn’t end up in a landfill because one part breaks. We’re making it easy for cyclists to choose sustainability without sacrificing performance.”

The Future of Green Wheels: What’s Next?

As demand for sustainable cycling gear grows, the industry is already looking ahead to even more eco-friendly innovations. Researchers at the University of Washington are developing bio-based carbon fiber—made from plant materials like flax and hemp—that’s fully biodegradable. Early tests show the material is 20% lighter than traditional carbon fiber and emits 50% less carbon during production.

Brands are also exploring carbon-neutral shipping: ENVE now uses electric delivery trucks for U.S. orders and offsets international shipping emissions through reforestation projects. And in 2025, the Global Cycling Federation (GCF) plans to launch a “Sustainable Wheel Certification” program, labeling wheels that meet strict standards for recycled materials, energy use, and recyclability.

For cyclists, this means more choices than ever to ride green. “You don’t have to compromise on speed or style to be sustainable,” says Lindgren. “The best carbon fiber wheels now are the ones that let you ride hard—and feel good about it.”

Conclusion: Ride Green, Ride Far

The shift to sustainable carbon fiber bike wheels is more than just an industry trend—it’s a commitment to protecting the planet we ride on. From recycled materials to energy-efficient factories and circular design, every innovation brings cyclists closer to a future where high-performance gear and environmental responsibility coexist.

Whether you’re a weekend commuter or a competitive racer, choosing a sustainable carbon fiber wheel isn’t just a purchase—it’s a statement. It says you care about the roads, trails, and mountains you ride, and that you want to keep them healthy for generations of cyclists to come.

As the industry continues to go green, one thing is clear: the future of cycling is light, fast, and sustainable. And it’s rolling out now.