Carbon fiber frames are expensive and fragile; they break easily if you fall? And if they break, they're completely unusable? Breaking Your Stereotypes About Carbon Frames.

Core Knowledge of Carbon Fiber Frames

What exactly is carbon fiber? These black filaments, ten times thinner than a human hair, are the famous carbon fibers. Although they feel soft to the touch, when thousands of these carbon filaments are woven into a fabric and coated with resin, their strength is 3-7 times that of steel. If this soft carbon fabric is like rebar, then the resin is like cement, forming an indestructible carbon fiber composite material.

How are Carbon Fiber Frames Made?

So how does carbon fiber transform into a bicycle frame? Road bike frames are made from a type of carbon fabric called "prepreg." This carbon fabric is pre-impregnated with resin, like a giant sticker that can be peeled off and applied to a mold, making it very convenient. Each piece of carbon fabric is then cut into different shapes; a single frame requires about 300 pieces of carbon fabric. For example, the Giant TCR adv 3 10th generation uses 270 pieces of carbon fabric, 30 fewer than the older model. This is the reason for its further weight reduction.

So why are some small manufacturers' carbon frames heavier than aluminum frames? The reason is that they are afraid the frame won't be stiff or strong enough,

so they add excessive amounts of carbon fabric, resulting in a carbon fiber frame that is almost as heavy as an aluminum frame. This shows that "thicker isn't always better" when it comes to carbon fabric. The entire frame is built by skilled craftsmen layering the carbon fabric onto the mold, a process that heavily relies on their experience.

After the entire frame is assembled, it is placed in a mold and heated for shaping. A basic carbon frame is then complete. Each frame then undergoes more than a dozen tests; if any part fails, the frame is scrapped or recycled, which is another reason why these frames are so expensive.

How to determine the quality of a carbon fiber frame?

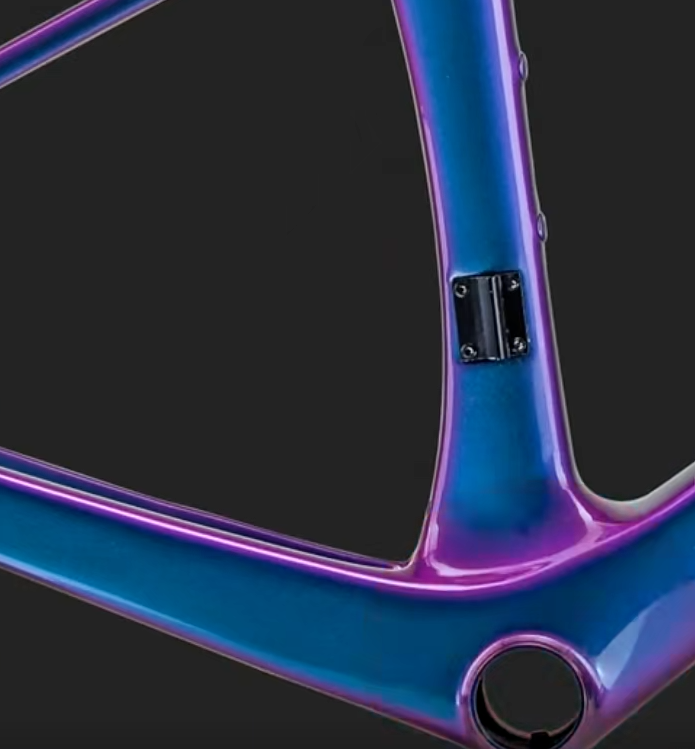

Some people will say to look at the carbon fiber grade! Like T800 is stronger than T700, but the frame quality isn't as dependent on the carbon fiber grade as you might think. The real determinant of a carbon frame's performance is the layup design. Layup design refers to how these 300 sheets of carbon fiber are applied? What angles are used (0°/45°/90°)? How many layers are applied to each part? Whether higher-grade carbon fiber is used to reinforce critical areas like the bottom bracket, head tube, and top tube. This is what truly determines the quality of a carbon frame.

For example, in this disassembled frame, you can see that the top tube uses higher-grade carbon fiber fabric to enhance local strength or rigidity, resulting in better rigidity and strength. In other words, even two frames made of the same Toray T1000 carbon fiber fabric can have significantly different rigidity, strength, and weight. It's like cooking; the same ingredients prepared by different chefs will result in noticeably different tastes. So, when you see T700, T800 reinforcement, or T1100+M40X reinforcement, it means that the frame uses higher-grade carbon fiber fabric in areas like the bottom bracket, enhancing the frame's rigidity and strength while further reducing weight. Its quality will definitely be better than a frame without carbon fiber reinforcement. Another point is to look at the inner wall craftsmanship; the smoother the inner wall, the better the factory's skill and quality control. If there are wrinkles or bubbles on the inner wall, these are the most likely places for future cracks to appear.

Misconceptions about Carbon Fiber Frames

Misconception 1: A carbon frame that "can be squeezed" = poor quality?

Many people like to "squeeze" carbon frames, and if they find certain areas can be pressed in, they conclude the frame is too soft, lacks rigidity, and is of poor quality. However, the fact that it can be squeezed doesn't necessarily mean the frame lacks rigidity. Excellent carbon frames, to achieve a balance of rigidity, strength, and lightweight properties, will use less carbon fiber in the downtube and chainstays, while using more in areas like the bottom bracket, top tube, and fork. Some people online, for sensationalism, tend to squeeze the areas with less carbon fiber.

This isn't cutting corners; some frames are indeed very hard in these areas, which only means the manufacturer used more carbon fiber, but this leads to increased weight. The lightweight advantage of carbon fiber is then lost. On the other hand, excessive rigidity prevents effective shock absorption, resulting in a less comfortable ride. However, if the bottom bracket and head tube can be easily squeezed, then you should be wary. These areas bear immense pedaling torque and control forces; significant deformation indicates insufficient layering or poor manufacturing, which is very unsafe.

Misconception 2: Are carbon frames really that easy to break?

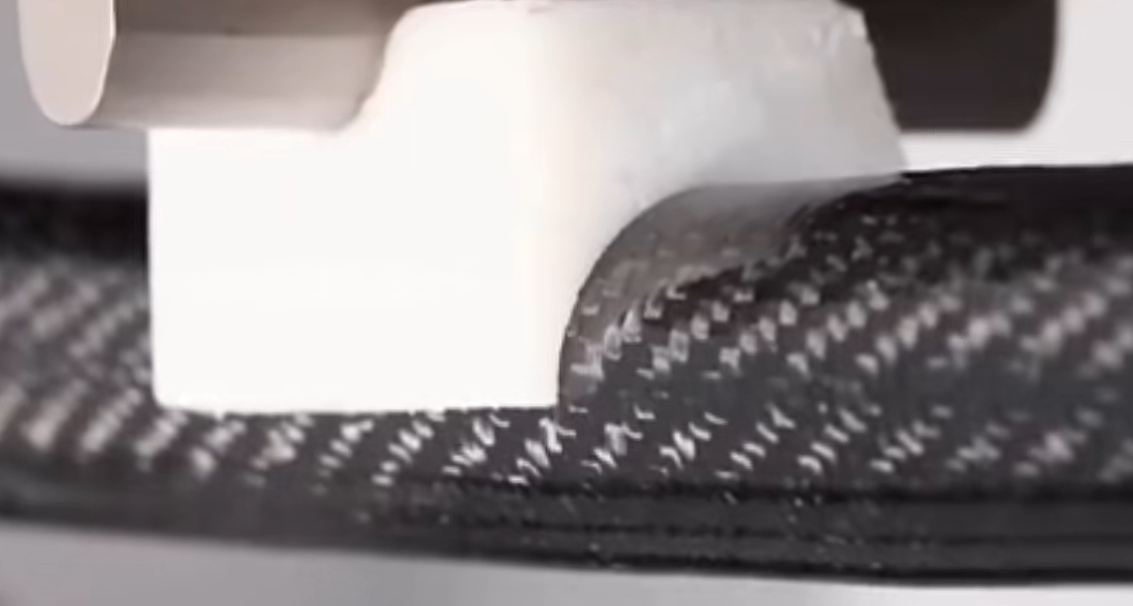

Carbon frames are not as fragile as we imagine. A blogger abroad conducted a test comparing the compressive strength of carbon fiber and aluminum alloy frames. In terms of compressive strength, carbon fiber can withstand approximately 2050 pounds of pressure, far exceeding the 1464 pounds of aluminum alloy. At the same time, carbon frames also have stronger impact resistance. Therefore, in most cases of normal falls, tumbles, or minor skids, carbon frames can withstand the impact. What carbon frames are really afraid of is not falls, but sharp objects. Because carbon fiber is essentially a fabric woven from threads, it has high hardness and strong toughness, but this is based on a large surface area of force. If a sharp object penetrates the carbon fiber material, it can directly destroy its structure. If you fall and hit a sharp stone, it may cause damage to the frame. So, carbon frames are not afraid of falling, but of being punctured.

Misconception 3: Do carbon frames only have a five-year lifespan?

Carbon fiber material itself is very durable and can last a very long time. The key factor affecting the carbon frame is the resin that binds the carbon fibers. In the past, resin technology was not good enough and aged faster.

However, mainstream manufacturers now use high-performance epoxy resins with mature processes, and they can easily last 8-10 years with normal riding. Resin is most afraid of ultraviolet rays, so as long as you avoid prolonged exposure to sunlight, riding for ten years is completely fine.

Have you been riding your carbon frame for several years and are looking to replace it?

Contact KOIBIKE; we are a professional wheelset manufacturing factory.