For most cyclists, the wheel set is the "foundation" of a smooth ride, and spokes, as the "skeleton" of the wheel set, directly determine its rigidity, stability, and service life. Many riders only notice spokes when there is an abnormal sound or loosening, but professional riders know that mastering the knowledge of spoke lacing methods and maintenance is the key to maximizing the performance of the wheel set. Today, we will decode the core secrets of spokes that are valued by pros.

Spoke Classification

According to head structure

Spokes can be divided into J-bend spokes and straight-drawn spokes based on their head structure.

J-bend spokes:The most common type of spoke has a 90° bend (shaped like a "J") at the end that connects to the hub, allowing it to hook into the hub flange hole. This design effectively prevents the spokes from twisting at the hub end, facilitating assembly and replacement, and is compatible with the vast majority of hubs. Hubs that accommodate J-shaped bend spokes have a simpler structure and are less expensive.

Straight-pull spokes:Because the spoke head has no bend, there's no need to worry about weak points at the hub-spoke connection, theoretically offering higher durability. However, wheel assembly and spoke replacement are more difficult. Straight-pull spokes lack the cushioning effect of bends, requiring precise alignment with the hub bore during installation. Furthermore, spoke head shapes vary between brands, resulting in poor interchangeability. Adjustment space during weaving is limited, leading to a low margin for error. If a spoke breaks, replacement often requires disassembling the freehub or even the tire. Additionally, if the spoke head isn't securely locked, it can easily rotate inside the hub. Therefore, the entire process demands specialized tools and considerable experience.

According to shaft shape

Spokes can be divided into constant diameter spokes and variable diameter spokes based on their shaft shape.

Constant diameter spokes (Straight Gauge Spokes)

Butted Spokes

Spoke Material

The material is a core factor determining spoke performance. Different materials directly affect the strength, weight, durability, and riding experience of the wheelset.

Stainless Steel: The most widely used spoke material, combining strength, durability, and corrosion resistance. It achieves a good balance between weight and performance, making it suitable for various riding scenarios. It is reliable and offers excellent value for money. However, compared to aluminum alloy or carbon fiber, it is heavier, which may be slightly insufficient for riders seeking extreme lightweight designs.

Aluminum alloy is lighter than stainless steel spokes, but has lower strength and is prone to fatigue after long-term use, posing a certain disadvantage in high-stress environments.

Titanium alloys are lighter than stainless steel, stronger than aluminum alloys, and possess excellent corrosion resistance. Furthermore, the slight elasticity of titanium alloys effectively improves riding comfort.

Carbon fiber is extremely lightweight, extremely rigid, and responsive, designed for ultimate aerodynamic efficiency. It's commonly used in road bikes and triathlon wheelsets, maximizing performance advantages in high-stakes races.

Notably, koibike's in-house carbon fiber spokes utilize a paint-free process that retains surface resin, optimizing toughness and effectively mitigating the bumps felt with traditional carbon spokes, thus improving riding comfort. Its extremely lightweight, high-strength, and direct energy transfer characteristics significantly enhance acceleration, climbing efficiency, and riding response.

Berd rope spokes are primarily made of Dyneema, a material also used in bulletproof vests, known for its exceptional strength-to-weight ratio and durability. Its strength-to-weight ratio is 12 times that of steel, its fatigue resistance is superior to steel spokes, and its lifespan is longer. Light enough to float on water, each spoke weighs only about 2.5g, while also providing excellent shock absorption for a more comfortable riding experience. Despite its higher price, its unique advantages make it a common choice for bicycles.

Spoke Lacing

Different lacing schemes affect the rim's strength, stiffness, and weight. Choose the right scheme based on your riding style and actual conditions.

Straight-Pull Lacing (OX): The spokes do not cross each other and connect directly radially from the hub to the rim. This lacing scheme puts more stress on the hub shell, so most hub manufacturers limit the maximum spoke tension to 100 kg/f.

The straight-pull lacing scheme is the shortest path connecting the hub and rim, resulting in the shortest spoke length and the lightest wheelset weight. However, its structural strength is relatively weak, and it is typically used on the front wheel of rim-brake road bikes, and occasionally on the non-drive side of the rear wheel.

Cross-lacing (2-Cross/3-Cross): Cross-lacing allows spokes to support each other, improving the overall rigidity and durability of the wheelset. Compared to straight-pull lacing (0X), cross-lacing has a significantly larger tangential angle, enhancing the wheelset's torque capacity.

2:1 Lacing: This refers to a 2:1 ratio of spokes on the drive side to spokes on the non-drive side. This lacing is commonly used on road bike rear wheels to handle asymmetrical forces generated by the drivetrain. By balancing the tension on both sides, it improves the overall strength and durability of the wheelset, reducing the risk of spoke breakage or wheelset deformation. Typically, spoke holes on hubs are evenly distributed, but there are exceptions: In Campagnolo G3 lacing, three spoke holes are grouped closely together, not following a uniform distribution rule.

Spoke Tension:

Hubs, rims, and spokes all have their respective manufacturer-recommended tension ranges. If a rim manufacturer states that its rims can withstand a tension of 140 kgf, while the hub manufacturer specifies a maximum of 120 kgf, the lower value should be used when assembling the wheels. Generally, the standard tension for most wheelsets is 120-130 kgf, unless certain components have pressure limitations.

Ensure that the tension on each spoke is even and within a reasonable range, while also following proper wheel assembly procedures such as stress relief. If your wheel assembler is not using a precisely calibrated tension meter or claims to rely on feel, this is undoubtedly a risky sign, and we recommend considering a more professional option (such as having us assemble the wheels for you before shipping).

Spoke Length:

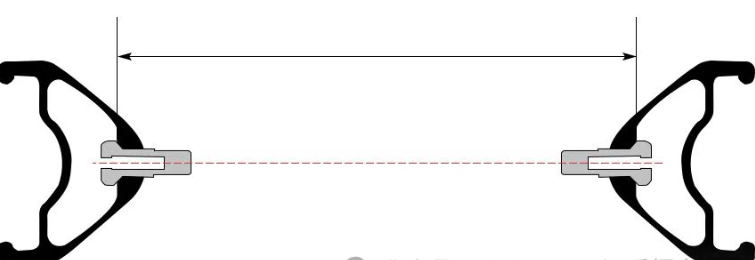

To accurately calculate the spoke length, you first need to obtain the effective diameter (ERD) of the rim. The ERD values for all LeBike rims are published on the corresponding product details page. Our ERD measurement standard is: the distance from the spoke cap base on one side of the rim to the spoke cap base on the other side (as shown in the picture), excluding the spoke tip length.

When using different types of spoke caps, adjustments to the calculation results may be necessary: Standard head external spoke caps: Most online calculators will provide the accurate length by simply entering our ERD.

Internal spoke caps: For 10mm spoke caps, add 8mm to the calculation result; for 12mm spoke caps, add 10mm; for 14mm spoke caps, add 12mm.

High-profile external spoke caps (such as DT Swiss Squorx or Double Square): Add 2mm to the calculation result to ensure the spoke length is appropriate.

Spoke Number and Hole Count:

The number of spokes on different bike models is directly related to load requirements.

For example, mountain bikes, such as XC bikes prioritizing lightweight design, often use a 28-hole design. AM bikes, also often using 28-hole for lightweight purposes, are similarly common. EN and DH bikes, requiring higher strength, typically use 32 or even 36-hole configurations.

Fat tire wheelsets, due to their wider rims and tires, often use 32-hole spokes to ensure support.

Rim brake road bikes commonly have 24-hole spokes on the rear wheel and 20 on the front. Disc brake road bikes currently primarily use a 24-hole design front and rear, while 28-hole designs are often used by heavier riders or those seeking higher strength.

Carbon fiber wheelsets rarely use a 36-hole configuration because the rim itself is more rigid than aluminum alloy, although some BMX bikes or touring wheelsets use this specification. Note that because the rear wheel needs to withstand greater impact loads and weight pressure, it usually has 4 more spokes than the front wheel.

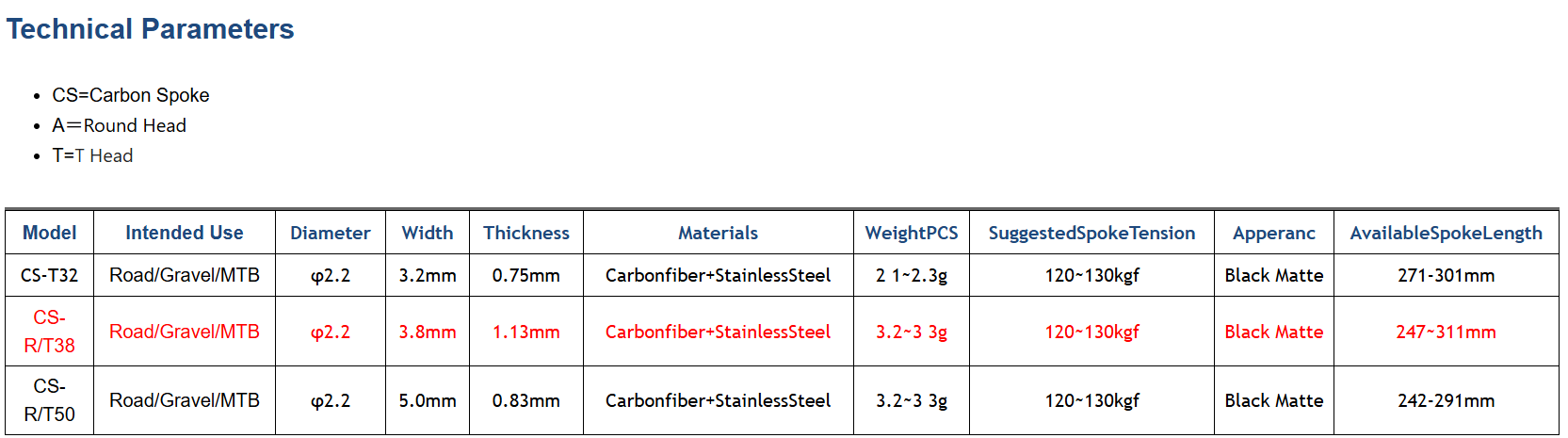

KOIBIKE's Spokes:

Spoke Routine Maintenance and Inspection

Spoke malfunctions (loosening, breakage) are common problems in cycling. Regular maintenance can extend their lifespan and avoid safety risks.

Visual Inspection: Observe the spokes for bends, rust, and broken strands, paying particular attention to the bends of J-shaped spokes and stress concentration areas in the thin sections of variable-diameter spokes. Rotate the wheelset to check if the gap between the rim and brake pads is uniform. If the runout exceeds 0.4mm, adjust it immediately.

Tactile Inspection: Gently tap each spoke with your finger. A crisp, consistent sound indicates even tension. If a spoke produces a dull sound, it is likely loose and needs to be calibrated with a tension meter.

For more detailed information on spoke tension adjustment and wheelset runout adjustment, please click: Beginner's Guide: From Tools to Adjustment, Carbon Fiber Wheelset Setup Guide

Cleaning: Clean the spokes with a soft brush or cloth. Avoid using materials that may scratch or damage the spokes. Dirt can be removed with neutral soap or bicycle cleaner. After cleaning, rinse thoroughly with water and dry completely with a cloth to prevent water residue from causing rust.

Lubrication: Apply a small amount of lubricant to the spoke cap and spoke junction. This effectively prevents seizing caused by oxidation or moisture and facilitates future adjustments.

Note: Avoid over-lubrication. Excess grease will attract dust and dirt, accelerating wear. After lubrication, wipe off any excess lubricant with a cloth.