Carbon fiber rims have different textures, including unidirectional (UD), multidirectional weaves (such as 1K, 3K, and 12K), and special textures (such as marble and butterfly patterns). The most common weave types are distinguished by the number of carbon fiber bundles and the weaving method. For example, UD weave is a unidirectional arrangement of carbon fibers, while the K number (1K, 3K, and 12K) indicates the number of carbon fiber bundles per millimeter of width. The weave method is further divided into plain and twill to achieve different visual and structural effects.

Carbon Fabric Textures: From Craftsmanship to Aesthetics

1. UD (Unidirectional) Texture: A Performance Aesthetic in Simplicity

The carbon fibers are arranged parallel in a single direction, without any interlaced grain. When exposed to light, the fine, luster-like texture reveals itself, creating a subtle, technological aesthetic. This texture's core advantage is "performance-first"—the fiber orientation aligns with the force applied to the rim, maximizing stiffness. This makes it the preferred choice for professional road racing wheels.

Variant Textures:

2. 3K Texture: A Delicate, Three-Dimensional Visual Focus

Each strand contains 3,000 carbon filaments, woven in a plain or twill weave to create a fine texture. This texture is more three-dimensional than UD texture, making it a popular choice for both aesthetics and value.

3K Plain Weave:

The texture features a small, checkered pattern with a delicate pattern. When paired with bright-colored frames (such as red or yellow), it creates a contrast between warm and cool, perfect for city commuting or casual riding, adding a touch of energy.

3K Twill:

The texture is angled at 45° for a more dynamic look. The horizontal twill creates a stable, well-suited look for retro-style frames, while the vertical twill creates a slender look, perfect for tall road rims, visually lengthening the rim's lines.

3K Honeycomb:

A special weaving process creates a hexagonal honeycomb structure with a higher density, resembling a "carbon fiber armor," giving it a technical and protective feel. It is commonly used on mountain bike or gravel rims.

3. 12K Twill: A Rugged, Powerful Look

Each strand contains 12,000 carbon filaments, with wider spacing between strands and thicker strands, creating a strong visual impact and instantly distinguishing it from other textures. Its primary application is mid-to-high rims (>40mm). The coarse grain balances the heaviness of taller rims, avoiding visual monotony.

For example, a 50mm-deep road rim paired with a 12K twill creates a sense of flow as the wheel rotates at high speeds, becoming the visual centerpiece of the bike. This is ideal for riders who appreciate a bold and individual look.

4. Special K-Value Textures: A Niche Choice

1K Texture: Each strand contains only 1,000 carbon filaments, with a texture as fine as gauze. It's primarily used in the bead area of the rim, where lightweighting and peel resistance are crucial. The 1K fine texture allows the carbon fabric to adhere more closely to the rim mold, enhancing sealing performance.

18K Texture: Each strand contains 18,000 carbon filaments, with a texture as rough as woven sack, offering an industrial aesthetic. It's used exclusively on heavy-duty mountain bike or fat tire rims. It can withstand the impacts of extreme off-roading, visually conveying a sense of ruggedness and durability.

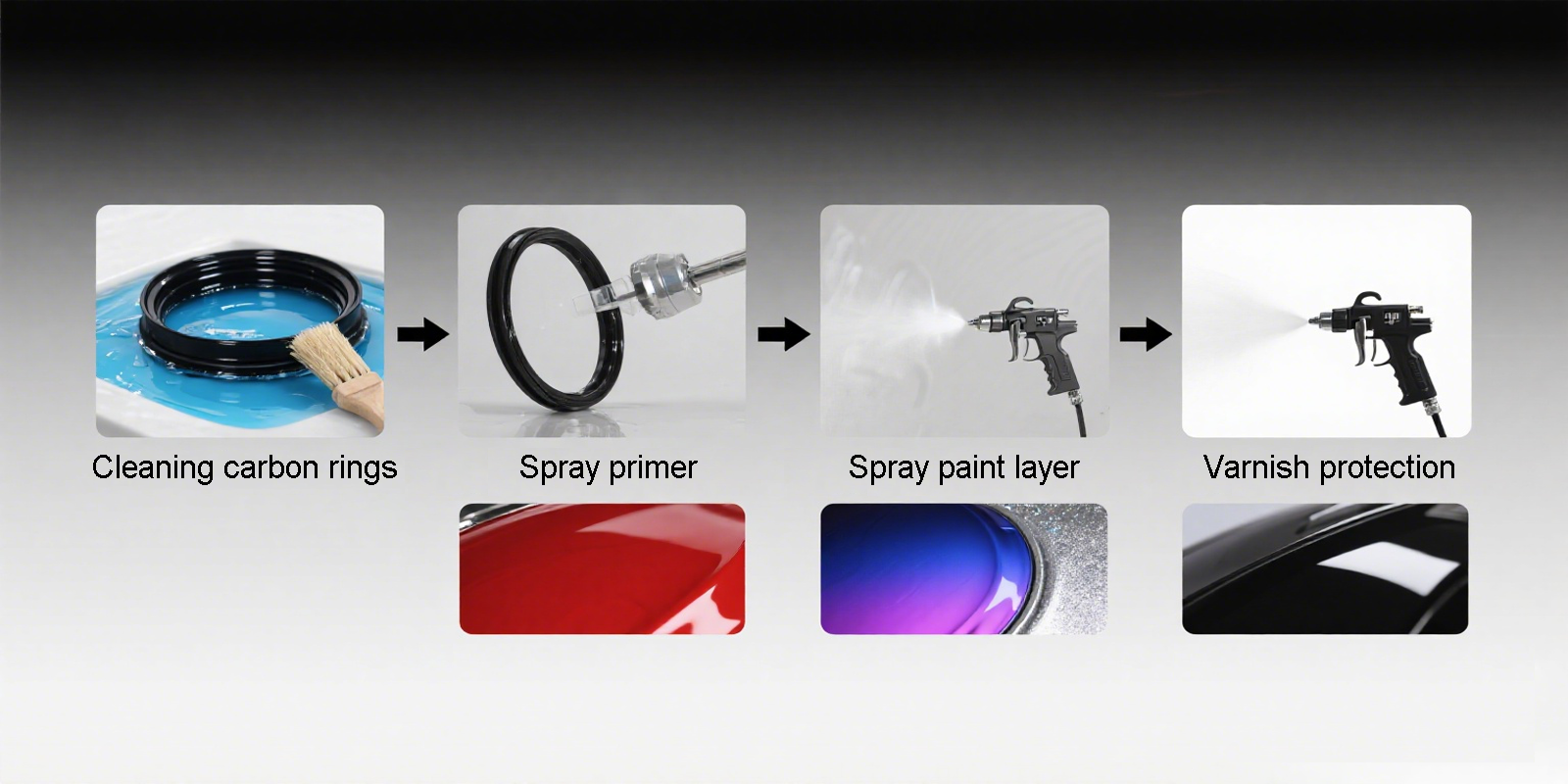

Painting: The Art of Color and Protection

If the carbon fabric texture is the "natural base," then the coating is the "icing on the cake"—it not only imparts a rich color to the rim, but also enhances surface wear resistance and extends its lifespan.

1. Color Coating: A Customized Color Spree

Spraying colored paint on the carbon rims creates a harmonious color connection between the frame and rims, a popular choice for personalized customization.

Popular Styles:

Gradient Paint: A light to dark blue transition paired with a white frame is ideal for summer riding, creating a visually cooling effect.

Chameleon Paint: A chromatic hue changes color depending on the lighting angle (e.g., purple in sunlight, green in shadow). This is ideal for competitors seeking a unique look, making it instantly recognizable on the track. Glitter Paint: Adding fine metallic glitter to the base paint creates a "starlight effect" in sunlight. However, be aware that the glitter adds approximately 5g to the weight, so lightweight enthusiasts should choose with caution.

2. Clearcoat: Rediscovering the True Beauty of Carbon Fiber

Spraying only the surface of the carbon rim with clear varnish, completely exposing the carbon fiber texture, is the preferred choice for performance enthusiasts. Compared to base paint, clearcoat can reduce weight by 15-20g while enhancing the natural texture of the carbon fiber.

Use Case: In professional road racing, most competitors choose clearcoat rims. This reduces weight while creating a clean visual combination of "carbon texture and racing suit color" that doesn't distract from the competition.

3. Textured Paint: A Niche, High-End Choice

Using a special process to create a three-dimensional texture on the paint surface, transcending the limitations of flat coatings. This is suitable for cyclists seeking a niche, high-end look.

Crystal Texture Paint: A mixture of distilled water, urea, and a wetting agent is sprayed on, creating a chemical reaction that creates a crystalline, concave and convex texture. Each wheel rim is unique, creating a signature imprint. However, please note: this process is complex, with a customization cycle of up to two weeks and an additional weight of approximately 30g.

Frosted Texture Paint: Frosted particles are added to the clear varnish to create a matte finish with a fine, grainy feel. It effectively resists fingerprints and minor scratches, making it suitable for everyday use and easier to maintain.

Pattern and Coating Compatibility Guide

Road Racing: UD Texture + Clear Coat / Light Gradient Paint, prioritizing lightweight and low drag.

Mountain Cross Country: 12K Texture + Matte Paint / Dark Paint, emphasizing durability and scratch resistance.

Urban Commuting: 3K Plain Texture + Glitter Paint / Bright Color Paint, balancing aesthetics with daily care. Gravel Cycling: Marble UD Grain + Clearcoat: Balancing Performance and Scratch Hiding.

From the simplicity of UD grain to the ruggedness of 12K, from the authenticity of clearcoat to the niche of crystal lacquer, the look and finish of carbon fiber rims have long been part of cycling culture. They're not just a vehicle for performance, but an extension of the rider's personality. Whether you're a competitive rider striving for extreme speed or a casual enthusiast enjoying the scenery, you can find your own unique cycling identity in the grain and color of carbon rims.